What is Global Laser Skin Resurfacing Machines Market?

The Global Laser Skin Resurfacing Machines Market refers to the worldwide industry focused on the production, distribution, and utilization of laser devices designed for skin resurfacing treatments. These machines use concentrated light beams to remove damaged skin layers, promoting the growth of new, healthier skin. The market encompasses a variety of laser technologies, including CO2 lasers, Nd:YAG lasers, and other types, each offering unique benefits for different skin conditions and types. The demand for these machines is driven by the growing interest in non-invasive cosmetic procedures, advancements in laser technology, and the increasing prevalence of skin-related issues such as acne scars, wrinkles, and pigmentation. The market serves a diverse range of end-users, including hospitals, clinics, and dermatology centers, reflecting its broad applicability in both medical and aesthetic fields. As more people seek effective and minimally invasive solutions for skin rejuvenation, the Global Laser Skin Resurfacing Machines Market continues to expand, offering innovative treatments that cater to varying patient needs and preferences.

CO2 Laser, Nd:YAG Laser, Others in the Global Laser Skin Resurfacing Machines Market:

CO2 lasers, Nd:YAG lasers, and other types of lasers play a significant role in the Global Laser Skin Resurfacing Machines Market, each bringing distinct advantages to the table. CO2 lasers are known for their precision and effectiveness in treating deep wrinkles, scars, and other severe skin imperfections. They work by emitting a concentrated beam of carbon dioxide, which vaporizes the outer layers of damaged skin, stimulating collagen production and promoting the growth of new skin. This type of laser is particularly favored for its ability to deliver dramatic results with relatively few treatments, although it may require a longer recovery period compared to other laser types. Nd:YAG lasers, on the other hand, are versatile and can penetrate deeper into the skin, making them suitable for treating vascular lesions, pigmentation issues, and even hair removal. They operate at a wavelength that allows them to target specific skin structures without damaging the surrounding tissue, which makes them a popular choice for patients seeking minimal downtime and reduced risk of side effects. Other types of lasers, such as Erbium lasers and fractional lasers, offer additional options for skin resurfacing. Erbium lasers are often used for more superficial skin issues, providing a gentler alternative to CO2 lasers with a shorter recovery time. Fractional lasers, which can be either CO2 or Erbium-based, create microscopic treatment zones, leaving surrounding tissue intact and thus speeding up the healing process. These lasers are particularly effective for treating fine lines, sun damage, and mild to moderate skin laxity. The diversity of laser technologies available in the market allows practitioners to tailor treatments to the specific needs of their patients, enhancing the overall effectiveness and satisfaction of laser skin resurfacing procedures. As technology continues to evolve, new laser systems are being developed that offer improved precision, safety, and patient comfort, further driving the growth and innovation within the Global Laser Skin Resurfacing Machines Market.

Hospitals, Clinics in the Global Laser Skin Resurfacing Machines Market:

The usage of Global Laser Skin Resurfacing Machines in hospitals and clinics highlights the versatility and effectiveness of these devices in various medical and aesthetic applications. In hospitals, laser skin resurfacing machines are often utilized in dermatology and plastic surgery departments to treat a wide range of skin conditions. These include severe acne scars, deep wrinkles, and other significant skin imperfections that require more intensive treatment. The advanced capabilities of CO2 and Nd:YAG lasers make them ideal for hospital settings, where patients may need more comprehensive care and monitoring. Hospitals also benefit from the ability to offer these treatments as part of a broader range of dermatological services, providing patients with access to cutting-edge technology and highly skilled medical professionals. In clinics, laser skin resurfacing machines are commonly used for cosmetic procedures aimed at improving the appearance of the skin. Clinics often cater to patients seeking non-invasive or minimally invasive treatments for issues such as fine lines, sun damage, and mild to moderate acne scars. The use of fractional lasers and Erbium lasers in these settings allows for effective treatment with minimal downtime, making them attractive options for patients with busy lifestyles. Clinics also benefit from the ability to offer personalized treatment plans, utilizing the diverse range of laser technologies available to address specific patient concerns. The growing popularity of aesthetic treatments has led to an increase in the number of clinics offering laser skin resurfacing, further expanding the market and making these treatments more accessible to a wider audience. Both hospitals and clinics play a crucial role in the Global Laser Skin Resurfacing Machines Market, leveraging the advanced capabilities of these devices to provide high-quality care and achieve optimal patient outcomes. As the demand for effective and minimally invasive skin treatments continues to rise, the adoption of laser skin resurfacing machines in these settings is expected to grow, driving further advancements and innovation in the field.

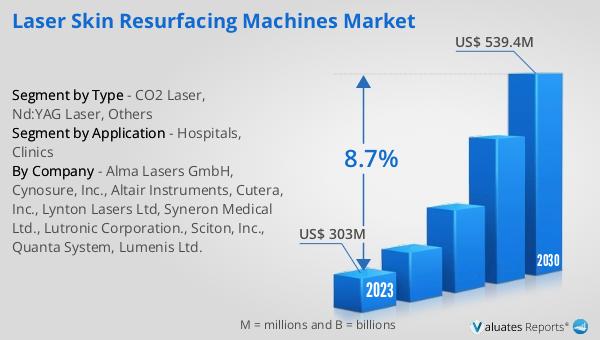

Global Laser Skin Resurfacing Machines Market Outlook:

The global Laser Skin Resurfacing Machines market was valued at US$ 303 million in 2023 and is anticipated to reach US$ 539.4 million by 2030, witnessing a CAGR of 8.7% during the forecast period 2024-2030. This significant growth reflects the increasing demand for advanced skin resurfacing treatments and the continuous advancements in laser technology. The market's expansion is driven by a combination of factors, including the rising prevalence of skin-related issues, the growing popularity of non-invasive cosmetic procedures, and the increasing availability of laser treatments in both medical and aesthetic settings. As more people seek effective solutions for skin rejuvenation, the adoption of laser skin resurfacing machines is expected to rise, contributing to the market's robust growth. The projected increase in market value underscores the importance of these devices in addressing a wide range of skin concerns and highlights the ongoing innovation and development within the industry. With a strong focus on improving patient outcomes and enhancing the overall effectiveness of treatments, the Global Laser Skin Resurfacing Machines Market is poised for continued growth and success in the coming years.

| Report Metric | Details |

| Report Name | Laser Skin Resurfacing Machines Market |

| Accounted market size in 2023 | US$ 303 million |

| Forecasted market size in 2030 | US$ 539.4 million |

| CAGR | 8.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | Alma Lasers GmbH, Cynosure, Inc., Altair Instruments, Cutera, Inc., Lynton Lasers Ltd, Syneron Medical Ltd., Lutronic Corporation., Sciton, Inc., Quanta System, Lumenis Ltd. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |