What is Concrete Temperature Sensor - Global Market?

Concrete temperature sensors are specialized devices used to monitor the temperature of concrete during its curing process. These sensors are crucial in ensuring the structural integrity and longevity of concrete structures. By providing real-time data, they help in maintaining optimal curing conditions, which is vital for preventing cracks and ensuring the concrete reaches its desired strength. The global market for concrete temperature sensors is expanding as construction projects worldwide increasingly adopt advanced technologies to enhance quality and efficiency. These sensors are used in various applications, including bridges, buildings, and roads, where precise temperature monitoring can significantly impact the outcome. The market's growth is driven by the rising demand for smart infrastructure and the need for efficient construction practices. As urbanization continues to rise, the importance of these sensors in ensuring safe and durable structures becomes even more pronounced. The integration of IoT and wireless technologies in these sensors further boosts their adoption, offering more convenience and accuracy in data collection and analysis. With the construction industry continuously evolving, the role of concrete temperature sensors is set to become even more critical in the coming years.

Thermocouples, Resistance Temperature Detector, Thermistors in the Concrete Temperature Sensor - Global Market:

Thermocouples, Resistance Temperature Detectors (RTDs), and Thermistors are three primary types of sensors used in the concrete temperature sensor market. Each of these sensors has unique characteristics that make them suitable for specific applications. Thermocouples are widely used due to their broad temperature range and durability. They consist of two different metals joined at one end, creating a junction where the temperature is measured. The voltage generated at this junction is proportional to the temperature difference between the junction and the other ends of the metals. This makes thermocouples ideal for environments where extreme temperatures are present, such as in concrete curing processes. Their robustness and ability to provide quick responses to temperature changes make them a popular choice in the construction industry. On the other hand, Resistance Temperature Detectors (RTDs) are known for their accuracy and stability. They work on the principle that the resistance of a metal changes with temperature. RTDs are typically made of pure platinum, which provides a linear and predictable change in resistance with temperature. This makes them highly reliable for precise temperature measurements, which is crucial in ensuring the quality of concrete curing. However, RTDs are generally more expensive than thermocouples, which can be a consideration in large-scale projects. Thermistors, another type of temperature sensor, are known for their sensitivity and fast response times. They are made of semiconductor materials that exhibit a significant change in resistance with temperature. This makes them highly sensitive to temperature changes, allowing for precise monitoring of concrete temperatures. However, thermistors have a limited temperature range compared to thermocouples and RTDs, which can restrict their use in certain applications. Despite this limitation, their cost-effectiveness and ease of use make them a viable option for many construction projects. In the global market, the choice between these sensors often depends on the specific requirements of the project, including the desired accuracy, temperature range, and budget. As technology advances, the integration of these sensors with wireless and IoT technologies is becoming more common, providing enhanced data collection and analysis capabilities. This integration allows for real-time monitoring and control, which is essential for optimizing the concrete curing process and ensuring the structural integrity of the final product. As the demand for smart construction solutions continues to grow, the role of these sensors in the concrete temperature sensor market is expected to expand, offering new opportunities for innovation and efficiency in the construction industry.

Manufacturing, Engineering, Architecture in the Concrete Temperature Sensor - Global Market:

Concrete temperature sensors play a vital role in various sectors, including manufacturing, engineering, and architecture. In the manufacturing sector, these sensors are used to monitor the temperature of concrete during the production process. This is crucial in ensuring that the concrete achieves the desired properties and strength. By providing real-time data, manufacturers can adjust the curing conditions to optimize the quality of the concrete. This not only enhances the durability of the final product but also reduces the risk of defects and failures. In engineering, concrete temperature sensors are used to monitor the temperature of concrete structures during construction. This is essential in ensuring that the concrete cures properly and achieves the required strength. Engineers rely on these sensors to provide accurate data on the temperature of the concrete, allowing them to make informed decisions about the construction process. This helps in preventing issues such as cracking and ensures the structural integrity of the final product. In architecture, concrete temperature sensors are used to monitor the temperature of concrete elements in buildings and other structures. This is important in ensuring that the concrete cures properly and achieves the desired aesthetic and functional properties. Architects rely on these sensors to provide accurate data on the temperature of the concrete, allowing them to make informed decisions about the design and construction of the structure. This helps in ensuring that the final product meets the desired specifications and is safe and durable. Overall, the use of concrete temperature sensors in these sectors is essential in ensuring the quality and durability of concrete structures. By providing real-time data, these sensors help in optimizing the curing process and ensuring that the concrete achieves the desired properties. This not only enhances the quality of the final product but also reduces the risk of defects and failures, making them an invaluable tool in the construction industry.

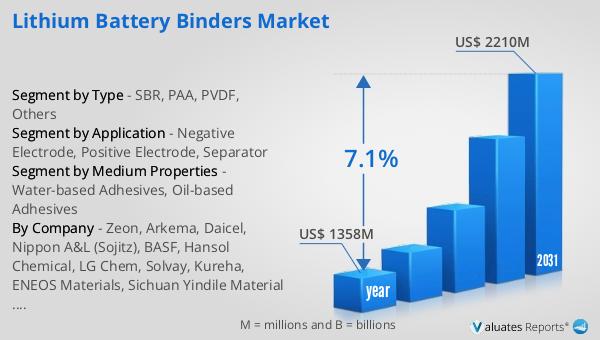

Concrete Temperature Sensor - Global Market Outlook:

The global market for concrete temperature sensors was valued at approximately $116.5 million in 2023. It is projected to grow to a revised size of around $179.9 million by 2030, reflecting a compound annual growth rate (CAGR) of 5.3% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for advanced monitoring solutions in the construction industry, driven by the need for enhanced quality control and efficiency in concrete curing processes. The North American market, in particular, is expected to see significant growth during this period, although specific figures were not provided. The adoption of concrete temperature sensors in this region is likely to be fueled by the ongoing development of smart infrastructure and the increasing emphasis on sustainable construction practices. As the construction industry continues to evolve, the role of concrete temperature sensors in ensuring the structural integrity and longevity of concrete structures is becoming increasingly important. The integration of these sensors with IoT and wireless technologies is expected to further drive market growth, offering more convenience and accuracy in data collection and analysis. Overall, the global market for concrete temperature sensors is poised for significant expansion in the coming years, driven by the growing demand for smart construction solutions and the need for efficient and reliable temperature monitoring in concrete curing processes.

| Report Metric | Details |

| Report Name | Concrete Temperature Sensor - Market |

| Forecasted market size in 2030 | US$ 179.9 million |

| CAGR | 5.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hilti, Giatec Scientific Inc., LumiCon, Doka, COMMAND Center, Kryton, AKCP |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |