What is Global Glass Bottle Inspection Machine Market?

The Global Glass Bottle Inspection Machine Market is a specialized segment within the broader industrial machinery market. These machines are designed to ensure the quality and integrity of glass bottles used in various industries, such as food and beverages, pharmaceuticals, and others. The primary function of these machines is to detect defects, contaminants, and inconsistencies in glass bottles, ensuring that only high-quality products reach the end consumer. The market for these machines has been growing steadily due to the increasing demand for quality assurance and safety in product packaging. Technological advancements have also played a significant role in the market's growth, with modern inspection machines now incorporating advanced features like high-speed cameras, X-ray systems, and machine vision technology. These innovations have made the inspection process more efficient and reliable, thereby driving the market forward. The global nature of this market means that manufacturers and suppliers are spread across various regions, each contributing to the overall growth and development of the industry.

X-Ray, Machine Vision, Others in the Global Glass Bottle Inspection Machine Market:

In the Global Glass Bottle Inspection Machine Market, different technologies are employed to ensure the quality and safety of glass bottles. One of the most commonly used technologies is X-ray inspection. X-ray machines are highly effective in detecting internal defects and contaminants that are not visible to the naked eye. They work by passing X-rays through the glass bottle and capturing the image on a detector. Any inconsistencies or foreign objects within the bottle will appear as dark spots on the image, allowing for easy identification and removal. This technology is particularly useful in industries where product safety is paramount, such as pharmaceuticals and food and beverages. Machine vision is another critical technology used in glass bottle inspection. Machine vision systems use high-speed cameras and sophisticated software algorithms to capture and analyze images of glass bottles. These systems can detect a wide range of defects, including cracks, chips, and surface irregularities. Machine vision technology is highly versatile and can be customized to meet the specific needs of different industries. For example, in the beverage industry, machine vision systems can be used to inspect the fill level of bottles, ensuring that each bottle contains the correct amount of liquid. In the pharmaceutical industry, these systems can verify the presence and accuracy of labels, ensuring that the right medication reaches the consumer. Other technologies used in the Global Glass Bottle Inspection Machine Market include ultrasonic inspection and infrared inspection. Ultrasonic inspection uses high-frequency sound waves to detect defects in glass bottles. This technology is particularly effective in identifying cracks and other structural weaknesses that may not be visible on the surface. Infrared inspection, on the other hand, uses infrared light to detect temperature variations in glass bottles. This technology can identify defects such as stress fractures and uneven thickness, which can compromise the integrity of the bottle. Each of these technologies has its own set of advantages and limitations. X-ray inspection is highly effective in detecting internal defects but can be expensive and requires specialized training to operate. Machine vision systems are versatile and can be customized for different applications, but they may struggle with detecting internal defects. Ultrasonic and infrared inspections are effective in identifying specific types of defects but may not be suitable for all applications. Despite these limitations, the combination of these technologies provides a comprehensive solution for ensuring the quality and safety of glass bottles. As the demand for high-quality products continues to grow, the Global Glass Bottle Inspection Machine Market is expected to see continued innovation and development in these technologies.

Food & Beverages, Pharmaceutical Industry, Others in the Global Glass Bottle Inspection Machine Market:

The Global Glass Bottle Inspection Machine Market finds extensive usage in various industries, including food and beverages, pharmaceuticals, and others. In the food and beverage industry, the quality and safety of packaging are of utmost importance. Glass bottles are commonly used for packaging beverages like water, soft drinks, and alcoholic beverages. Inspection machines in this industry are used to detect defects such as cracks, chips, and contamination that could compromise the safety and quality of the product. For instance, a cracked bottle could lead to leakage, while contamination could pose serious health risks to consumers. By ensuring that only defect-free bottles are used, these machines help maintain the integrity of the product and protect consumer health. In the pharmaceutical industry, the stakes are even higher. Glass bottles are often used to package liquid medications, vaccines, and other pharmaceutical products. Any defect in the bottle could compromise the efficacy of the medication and pose serious health risks to patients. Inspection machines in this industry are used to detect a wide range of defects, including cracks, chips, and contamination. They also verify the presence and accuracy of labels, ensuring that the right medication reaches the right patient. Given the stringent regulatory requirements in the pharmaceutical industry, the use of inspection machines is not just a matter of quality assurance but also a regulatory necessity. Other industries that use glass bottle inspection machines include cosmetics, chemicals, and personal care products. In the cosmetics industry, for example, glass bottles are used to package products like perfumes, lotions, and serums. Any defect in the bottle could compromise the quality and safety of the product, leading to customer dissatisfaction and potential health risks. Inspection machines help ensure that only high-quality bottles are used, thereby protecting the brand's reputation and ensuring customer satisfaction. In the chemicals industry, glass bottles are used to package various chemicals and reagents. Any defect in the bottle could lead to leakage or contamination, posing serious safety risks. Inspection machines help detect and eliminate defective bottles, ensuring the safety and integrity of the product. In summary, the Global Glass Bottle Inspection Machine Market plays a crucial role in ensuring the quality and safety of products across various industries. By detecting and eliminating defective bottles, these machines help protect consumer health, ensure regulatory compliance, and maintain the integrity of the product. As the demand for high-quality products continues to grow, the importance of glass bottle inspection machines is only expected to increase.

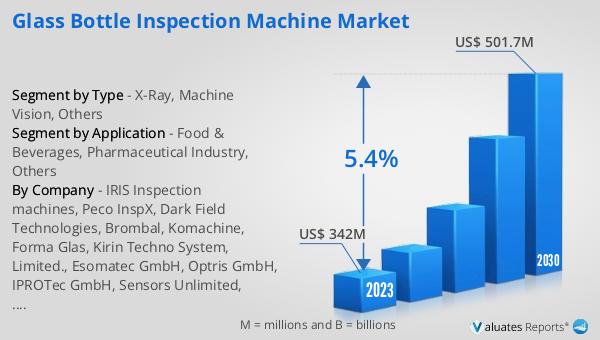

Global Glass Bottle Inspection Machine Market Outlook:

The global Glass Bottle Inspection Machine market was valued at US$ 342 million in 2023 and is anticipated to reach US$ 501.7 million by 2030, witnessing a CAGR of 5.4% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory driven by increasing demand for quality assurance and safety in product packaging. The valuation of US$ 342 million in 2023 reflects the current market size, which is already substantial. However, the projected growth to US$ 501.7 million by 2030 underscores the expanding need for advanced inspection technologies. The compound annual growth rate (CAGR) of 5.4% further highlights the market's robust growth potential. This growth can be attributed to several factors, including technological advancements, increasing regulatory requirements, and rising consumer awareness about product safety. As industries continue to prioritize quality and safety, the demand for glass bottle inspection machines is expected to rise, driving market growth. This positive market outlook suggests that manufacturers and suppliers in this industry have significant opportunities for expansion and innovation in the coming years.

| Report Metric | Details |

| Report Name | Glass Bottle Inspection Machine Market |

| Accounted market size in 2023 | US$ 342 million |

| Forecasted market size in 2030 | US$ 501.7 million |

| CAGR | 5.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | IRIS Inspection machines, Peco InspX, Dark Field Technologies, Brombal, Komachine, Forma Glas, Kirin Techno System, Limited., Esomatec GmbH, Optris GmbH, IPROTec GmbH, Sensors Unlimited, Bucher Emhart Glass, Mettler Toledo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |