What is Large Rotary Damper - Global Market?

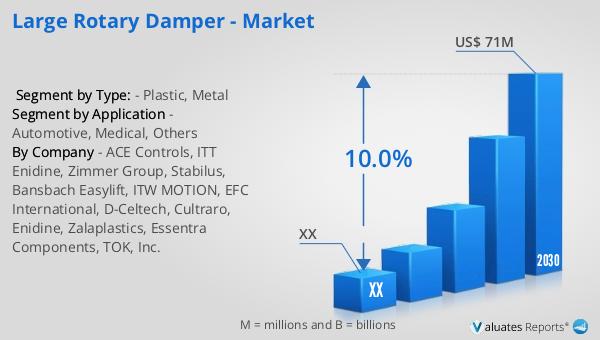

Large rotary dampers are essential components in various industries, designed to control motion by providing resistance to rotational movement. These devices are crucial in applications where smooth and controlled motion is necessary, such as in automotive, medical, and consumer electronics. The global market for large rotary dampers is expanding due to the increasing demand for precision and reliability in these sectors. In 2023, the market was valued at approximately US$ 39 million, and it is projected to grow significantly, reaching an estimated US$ 71 million by 2030. This growth is driven by a compound annual growth rate (CAGR) of 10.0% from 2024 to 2030. The North American market, in particular, is expected to see substantial growth, reflecting the region's technological advancements and industrial needs. As industries continue to innovate and seek more efficient solutions, the demand for large rotary dampers is likely to rise, making them a critical component in the global market landscape. These dampers not only enhance product performance but also contribute to safety and durability, making them indispensable in modern engineering applications. The market's growth trajectory underscores the increasing importance of motion control solutions in various high-tech and industrial applications.

Plastic, Metal in the Large Rotary Damper - Global Market:

In the realm of large rotary dampers, materials play a pivotal role in determining the performance and durability of these components. Plastic and metal are the two primary materials used in their construction, each offering distinct advantages and challenges. Plastic rotary dampers are favored for their lightweight nature and cost-effectiveness. They are particularly useful in applications where weight reduction is crucial, such as in consumer electronics and certain automotive components. Plastics offer excellent resistance to corrosion and can be molded into complex shapes, providing flexibility in design. However, they may not always provide the same level of strength and heat resistance as metal dampers, which can limit their use in high-stress or high-temperature environments. On the other hand, metal rotary dampers are renowned for their robustness and durability. Metals such as aluminum and stainless steel are commonly used, offering superior strength and the ability to withstand extreme conditions. Metal dampers are ideal for applications requiring high load-bearing capacity and long-term reliability, such as in industrial machinery and heavy-duty automotive parts. They also provide better thermal conductivity, which can be advantageous in applications where heat dissipation is a concern. However, metal dampers are generally heavier and more expensive than their plastic counterparts, which can be a drawback in applications where weight and cost are critical considerations. The choice between plastic and metal dampers often depends on the specific requirements of the application, including factors such as load, environmental conditions, and budget constraints. As the global market for large rotary dampers continues to grow, advancements in material science are likely to lead to the development of new materials and composites that combine the best properties of both plastic and metal. This could result in dampers that offer enhanced performance, greater durability, and improved cost-effectiveness, further driving the adoption of these components across various industries. The ongoing research and development in this field highlight the dynamic nature of the market and the continuous quest for innovation to meet the evolving needs of modern engineering applications.

Automotive, Medical, Others in the Large Rotary Damper - Global Market:

Large rotary dampers find extensive usage across various sectors, with automotive, medical, and other industries being significant contributors to their demand. In the automotive sector, these dampers are crucial for enhancing vehicle performance and passenger comfort. They are used in applications such as seat adjusters, glove box dampers, and center console lids, where controlled motion is essential to prevent abrupt movements and ensure smooth operation. The use of rotary dampers in automotive applications not only improves the user experience but also contributes to the longevity of vehicle components by reducing wear and tear. In the medical field, large rotary dampers play a vital role in ensuring the precision and reliability of medical devices. They are used in equipment such as hospital beds, patient lifts, and diagnostic machines, where controlled motion is critical for patient safety and accurate operation. The ability of rotary dampers to provide consistent resistance and smooth motion makes them indispensable in medical applications, where even minor deviations can have significant consequences. Beyond automotive and medical applications, large rotary dampers are also used in a variety of other industries, including consumer electronics, furniture, and industrial machinery. In consumer electronics, they are used in devices such as laptops and cameras to provide smooth opening and closing actions, enhancing user experience and product durability. In the furniture industry, rotary dampers are used in applications such as cabinet doors and drawers to ensure soft closing and prevent slamming, which can damage the furniture and pose safety risks. In industrial machinery, these dampers are used to control the motion of moving parts, reducing the risk of mechanical failure and improving operational efficiency. The versatility and effectiveness of large rotary dampers make them a valuable component in a wide range of applications, driving their demand in the global market. As industries continue to innovate and seek more efficient solutions, the usage of large rotary dampers is expected to expand, further solidifying their position as a critical component in modern engineering applications.

Large Rotary Damper - Global Market Outlook:

The global market for large rotary dampers was valued at approximately US$ 39 million in 2023, with projections indicating a significant increase to US$ 71 million by 2030. This growth is driven by a compound annual growth rate (CAGR) of 10.0% during the forecast period from 2024 to 2030. The North American market, in particular, is poised for substantial growth, reflecting the region's technological advancements and industrial needs. While specific figures for the North American market were not provided, it is clear that the region will play a crucial role in the overall market expansion. The increasing demand for precision and reliability in various sectors, including automotive, medical, and consumer electronics, is a key factor driving the growth of the large rotary damper market. As industries continue to innovate and seek more efficient solutions, the demand for these components is expected to rise, making them an essential part of the global market landscape. The projected growth underscores the importance of motion control solutions in modern engineering applications, highlighting the critical role that large rotary dampers play in enhancing product performance, safety, and durability. As the market continues to evolve, advancements in material science and engineering are likely to lead to the development of new and improved dampers, further driving their adoption across various industries.

| Report Metric | Details |

| Report Name | Large Rotary Damper - Market |

| Forecasted market size in 2030 | US$ 71 million |

| CAGR | 10.0% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | ACE Controls, ITT Enidine, Zimmer Group, Stabilus, Bansbach Easylift, ITW MOTION, EFC International, D-Celtech, Cultraro, Enidine, Zalaplastics, Essentra Components, TOK, Inc. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |