What is Global Drug Transporter Service Market?

The Global Drug Transporter Service Market is a specialized sector within the pharmaceutical industry that focuses on the study and application of drug transporters. These transporters are proteins that play a crucial role in the absorption, distribution, and elimination of drugs within the human body. By understanding how these transporters work, pharmaceutical companies can develop more effective and safer medications. The market for these services includes various activities such as in vitro and in vivo testing, transporter assays, and consulting services. These services help in predicting drug-drug interactions, optimizing drug formulations, and ensuring regulatory compliance. The growing demand for personalized medicine and the increasing complexity of drug development are driving the growth of this market. Companies and research institutions are investing heavily in this area to gain a competitive edge and improve patient outcomes. The Global Drug Transporter Service Market is essential for advancing our understanding of drug behavior and enhancing the efficacy and safety of pharmaceutical products.

ABC Transporters, SLC Transporters in the Global Drug Transporter Service Market:

ABC Transporters and SLC Transporters are two major types of drug transporters that are extensively studied within the Global Drug Transporter Service Market. ABC (ATP-Binding Cassette) Transporters are a large family of proteins that utilize ATP hydrolysis to transport various molecules across cellular membranes. These transporters are known for their role in multidrug resistance, particularly in cancer cells, where they pump out chemotherapeutic agents, rendering treatments less effective. ABC Transporters are also involved in the transport of lipids, bile acids, and other endogenous substances. On the other hand, SLC (Solute Carrier) Transporters are a diverse group of membrane proteins that facilitate the movement of a wide range of solutes, including ions, sugars, amino acids, and drugs, across cellular membranes. Unlike ABC Transporters, SLC Transporters do not use ATP for their function but rely on ion gradients and other mechanisms. These transporters are crucial for drug absorption in the intestines, drug distribution in tissues, and drug elimination in the liver and kidneys. The study of these transporters involves various techniques such as gene expression analysis, transporter assays, and computational modeling. Understanding the function and regulation of ABC and SLC Transporters is vital for predicting drug-drug interactions, optimizing drug dosing, and minimizing adverse effects. The Global Drug Transporter Service Market provides the necessary tools and expertise to conduct these studies, thereby aiding in the development of safer and more effective drugs.

Enterprise, Hospital in the Global Drug Transporter Service Market:

The usage of Global Drug Transporter Service Market in enterprises and hospitals is multifaceted and essential for improving healthcare outcomes. In enterprises, particularly pharmaceutical and biotechnology companies, these services are used to streamline the drug development process. By understanding how drugs interact with transporters, companies can predict potential drug-drug interactions and optimize drug formulations. This not only speeds up the development process but also reduces the risk of late-stage failures, saving both time and resources. Additionally, these services help in ensuring regulatory compliance by providing the necessary data to meet the stringent requirements set by health authorities. In hospitals, the application of drug transporter services is equally important. Hospitals use these services to personalize patient treatment plans. By analyzing how a patient's body will absorb, distribute, and eliminate a drug, healthcare providers can tailor treatments to achieve the best possible outcomes. This is particularly important for patients with complex medical conditions who are on multiple medications. Understanding drug transporters can help in avoiding adverse drug reactions and ensuring that patients receive the most effective treatment. Furthermore, hospitals can use these services to conduct clinical research, contributing to the broader medical knowledge and improving future patient care. Overall, the Global Drug Transporter Service Market plays a crucial role in both enterprise and hospital settings by enhancing drug development and patient care.

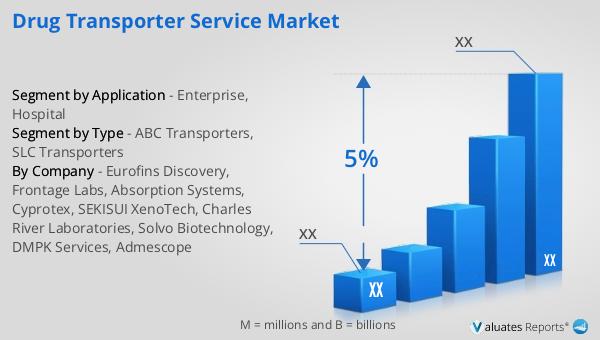

Global Drug Transporter Service Market Outlook:

The global pharmaceutical market was valued at approximately 1,475 billion USD in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5% over the next six years. In comparison, the chemical drug market has shown significant growth as well. It was estimated to increase from 1,005 billion USD in 2018 to 1,094 billion USD in 2022. This growth highlights the expanding demand for pharmaceutical products and the continuous advancements in drug development. The increase in market size reflects the industry's efforts to address various medical needs and improve patient outcomes. The data underscores the importance of the pharmaceutical sector in the global economy and its potential for future growth.

| Report Metric | Details |

| Report Name | Drug Transporter Service Market |

| CAGR | 5% |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Eurofins Discovery, Frontage Labs, Absorption Systems, Cyprotex, SEKISUI XenoTech, Charles River Laboratories, Solvo Biotechnology, DMPK Services, Admescope |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |