What is Global Laser Direct Imaging (LDI) System for IC Substrates Market?

The Global Laser Direct Imaging (LDI) System for IC Substrates Market refers to the industry focused on the production and utilization of LDI systems specifically designed for integrated circuit (IC) substrates. These systems use laser technology to directly image circuit patterns onto substrates, which are the base materials used in the manufacturing of ICs. This method offers high precision and efficiency, making it a preferred choice in the semiconductor industry. The market encompasses various types of LDI systems, including full-automatic, semi-automated, and manually operated systems, each catering to different levels of production needs and technological capabilities. The growing demand for miniaturized and high-performance electronic devices drives the need for advanced LDI systems, as they enable the creation of finer and more complex circuit patterns. This market is crucial for the advancement of semiconductor technology, supporting the production of a wide range of electronic components used in consumer electronics, automotive, telecommunications, and other industries. The continuous innovation and development in LDI technology are expected to further enhance the capabilities and applications of IC substrates, contributing to the overall growth and evolution of the semiconductor industry.

Full-Automatic Direct Imaging System, Semi-automated and Manually LDI System in the Global Laser Direct Imaging (LDI) System for IC Substrates Market:

The Full-Automatic Direct Imaging System in the Global Laser Direct Imaging (LDI) System for IC Substrates Market represents the pinnacle of automation and precision. These systems are designed to operate with minimal human intervention, utilizing advanced software and robotics to handle the entire imaging process. This includes substrate loading, alignment, imaging, and unloading, ensuring consistent quality and high throughput. Full-automatic systems are ideal for large-scale production environments where efficiency and accuracy are paramount. They are equipped with sophisticated features such as real-time monitoring, automatic calibration, and error detection, which help in maintaining optimal performance and reducing downtime. On the other hand, Semi-automated LDI systems offer a balance between automation and manual control. These systems typically require human intervention for certain tasks such as substrate loading and unloading, while the imaging process itself is automated. Semi-automated systems are suitable for medium-scale production environments where flexibility and cost-effectiveness are important. They provide a good compromise between the high cost of full-automatic systems and the labor-intensive nature of manual systems. Manually operated LDI systems, as the name suggests, rely heavily on human operators to perform most of the tasks. These systems are generally used in small-scale production or research and development settings where the volume of substrates to be imaged is relatively low. Manual systems offer the highest level of control and flexibility, allowing operators to make adjustments and modifications as needed. However, they are also the most labor-intensive and time-consuming, making them less suitable for high-volume production. Each type of LDI system has its own set of advantages and limitations, and the choice of system depends on factors such as production volume, budget, and specific application requirements. The diversity of LDI systems available in the market ensures that there is a suitable solution for different production needs, from high-volume manufacturing to specialized research and development projects.

FC-BGA (ABF), FC-CSP, BGA/CSP, SiP and RF Modules in the Global Laser Direct Imaging (LDI) System for IC Substrates Market:

The usage of Global Laser Direct Imaging (LDI) System for IC Substrates Market spans several critical areas, including FC-BGA (ABF), FC-CSP, BGA/CSP, SiP, and RF Modules. FC-BGA (Flip Chip Ball Grid Array) substrates, often made from Ajinomoto Build-up Film (ABF), require high precision and fine line imaging capabilities, which LDI systems provide. These substrates are used in high-performance computing and networking applications, where the accuracy and reliability of the circuit patterns are crucial. LDI systems enable the production of complex and dense circuit patterns on FC-BGA substrates, ensuring optimal performance and functionality. FC-CSP (Flip Chip Chip Scale Package) substrates also benefit from LDI technology, as they require precise imaging to accommodate the small size and high density of the circuits. These substrates are commonly used in mobile devices and other compact electronic products, where space is at a premium. LDI systems help in achieving the necessary miniaturization and integration of components, enhancing the overall performance and efficiency of the devices. BGA (Ball Grid Array) and CSP (Chip Scale Package) substrates, used in a wide range of electronic applications, also rely on LDI systems for accurate and efficient imaging. These substrates require fine line and space capabilities to support the high-density interconnections needed for modern electronic devices. LDI technology ensures that the circuit patterns are accurately imaged, reducing the risk of defects and improving the reliability of the final products. SiP (System in Package) technology, which integrates multiple ICs and passive components into a single package, also benefits from LDI systems. The complexity and density of the circuit patterns in SiP require high precision imaging, which LDI systems provide. This technology is used in various applications, including consumer electronics, automotive, and telecommunications, where the integration of multiple functions into a single package is essential. RF (Radio Frequency) Modules, used in wireless communication devices, also require precise and accurate imaging of circuit patterns. LDI systems enable the production of high-frequency circuits with minimal signal loss and interference, ensuring optimal performance of the RF modules. The versatility and precision of LDI technology make it an essential tool in the production of various IC substrates, supporting the advancement of semiconductor technology and the development of high-performance electronic devices.

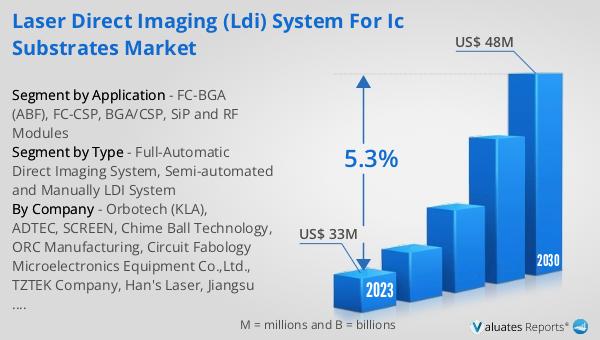

Global Laser Direct Imaging (LDI) System for IC Substrates Market Outlook:

The global Laser Direct Imaging (LDI) System for IC Substrates market was valued at US$ 33 million in 2023 and is anticipated to reach US$ 48 million by 2030, witnessing a CAGR of 5.3% during the forecast period 2024-2030. This market outlook highlights the steady growth and increasing demand for LDI systems in the semiconductor industry. The projected growth reflects the rising need for advanced imaging solutions to support the production of high-performance IC substrates. As electronic devices continue to evolve and become more complex, the demand for precise and efficient imaging technologies like LDI is expected to grow. The market's expansion is driven by the continuous innovation and development in LDI technology, which enhances the capabilities and applications of IC substrates. The increasing adoption of LDI systems in various applications, including FC-BGA, FC-CSP, BGA/CSP, SiP, and RF Modules, further underscores the importance of this technology in the semiconductor industry. The market outlook indicates a positive trend, with significant opportunities for growth and development in the coming years. The steady increase in market value and the projected CAGR demonstrate the critical role of LDI systems in advancing semiconductor technology and supporting the production of high-performance electronic devices.

| Report Metric | Details |

| Report Name | Laser Direct Imaging (LDI) System for IC Substrates Market |

| Accounted market size in 2023 | US$ 33 million |

| Forecasted market size in 2030 | US$ 48 million |

| CAGR | 5.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Orbotech (KLA), ADTEC, SCREEN, Chime Ball Technology, ORC Manufacturing, Circuit Fabology Microelectronics Equipment Co.,Ltd., TZTEK Company, Han's Laser, Jiangsu Yingsu IC Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |