What is Global Laser Processing Machine for IC Substrates Market?

The Global Laser Processing Machine for IC Substrates Market refers to the industry focused on the production and utilization of laser processing machines specifically designed for integrated circuit (IC) substrates. These machines are essential in the semiconductor manufacturing process, where precision and accuracy are paramount. IC substrates serve as the foundation for semiconductor devices, providing the necessary support and electrical connections. Laser processing machines are employed to perform various tasks such as drilling, cutting, and patterning on these substrates. The market for these machines is driven by the increasing demand for advanced electronic devices, miniaturization of components, and the need for high-performance semiconductors. As technology continues to evolve, the demand for more efficient and precise laser processing machines is expected to grow, making this market a critical component of the semiconductor industry.

Drilling Machine for IC Substrate, Laser Direct Imaging (LDI) for IC Substrate in the Global Laser Processing Machine for IC Substrates Market:

Drilling machines for IC substrates are specialized laser processing machines designed to create precise holes or vias in the substrate material. These holes are essential for establishing electrical connections between different layers of the substrate, enabling the integration of complex circuitry. The drilling process requires high precision and accuracy to ensure the reliability and performance of the final semiconductor device. Laser Direct Imaging (LDI) for IC substrates is another critical application of laser processing machines. LDI technology uses laser beams to directly transfer circuit patterns onto the substrate, eliminating the need for traditional photomasks. This process offers several advantages, including higher resolution, improved accuracy, and reduced production time. LDI is particularly beneficial for the production of high-density interconnects and fine-pitch circuitry, which are essential for advanced electronic devices. The global market for laser processing machines for IC substrates encompasses a wide range of applications, including drilling, cutting, and patterning. These machines are used in various stages of semiconductor manufacturing, from the initial substrate preparation to the final assembly of the device. The demand for laser processing machines is driven by the increasing complexity of semiconductor devices, the need for higher performance, and the trend towards miniaturization. As the semiconductor industry continues to evolve, the role of laser processing machines in ensuring the precision and reliability of IC substrates becomes increasingly important. The market is characterized by continuous innovation and technological advancements, with manufacturers constantly developing new and improved laser processing solutions to meet the growing demands of the industry. The integration of advanced features such as automation, real-time monitoring, and adaptive control systems further enhances the capabilities of these machines, making them indispensable tools in the semiconductor manufacturing process. Overall, the global laser processing machine for IC substrates market plays a crucial role in the production of high-performance semiconductor devices, supporting the ongoing advancements in electronics and technology.

FC-BGA, FC-CSP, BGA/CSP, SiP and RF Modules in the Global Laser Processing Machine for IC Substrates Market:

The usage of global laser processing machines for IC substrates extends to various areas, including FC-BGA, FC-CSP, BGA/CSP, SiP, and RF modules. FC-BGA (Flip Chip Ball Grid Array) is a packaging technology that involves flipping the chip and attaching it to the substrate using solder balls. Laser processing machines are used to create precise vias and patterns on the substrate, ensuring reliable electrical connections and optimal performance. FC-CSP (Flip Chip Chip Scale Package) is another packaging technology that benefits from laser processing machines. These machines enable the creation of fine-pitch circuitry and high-density interconnects, which are essential for the compact and efficient design of FC-CSP packages. BGA (Ball Grid Array) and CSP (Chip Scale Package) are widely used packaging technologies in the semiconductor industry. Laser processing machines are employed to drill vias, cut substrates, and pattern circuits, ensuring the accuracy and reliability of these packages. SiP (System in Package) is an advanced packaging technology that integrates multiple semiconductor devices into a single package. Laser processing machines play a crucial role in the production of SiP by enabling the precise drilling, cutting, and patterning of substrates, ensuring the seamless integration of different components. RF modules, which are used in wireless communication devices, also benefit from laser processing machines. These machines enable the creation of high-frequency circuits and interconnects, ensuring the performance and reliability of RF modules. The versatility and precision of laser processing machines make them indispensable tools in the production of various semiconductor packages, supporting the ongoing advancements in electronics and technology. The demand for these machines is driven by the increasing complexity of semiconductor devices, the need for higher performance, and the trend towards miniaturization. As the semiconductor industry continues to evolve, the role of laser processing machines in ensuring the precision and reliability of IC substrates becomes increasingly important. The market is characterized by continuous innovation and technological advancements, with manufacturers constantly developing new and improved laser processing solutions to meet the growing demands of the industry. Overall, the usage of global laser processing machines for IC substrates in FC-BGA, FC-CSP, BGA/CSP, SiP, and RF modules highlights their critical role in the production of high-performance semiconductor devices.

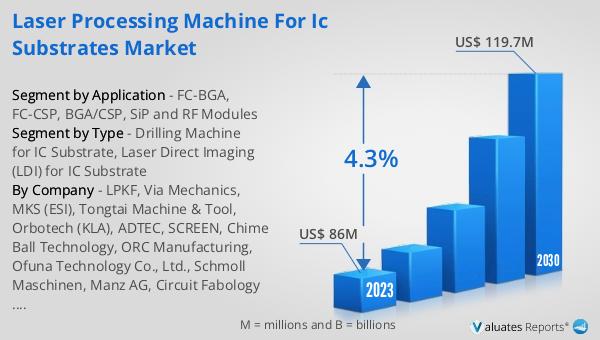

Global Laser Processing Machine for IC Substrates Market Outlook:

The global market for Laser Processing Machines for IC Substrates was valued at $86 million in 2023 and is projected to grow to $119.7 million by 2030, reflecting a compound annual growth rate (CAGR) of 4.3% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for advanced electronic devices, the trend towards miniaturization, and the need for high-performance semiconductors. As technology continues to evolve, the demand for more efficient and precise laser processing machines is expected to grow, making this market a critical component of the semiconductor industry. The market is characterized by continuous innovation and technological advancements, with manufacturers constantly developing new and improved laser processing solutions to meet the growing demands of the industry. The integration of advanced features such as automation, real-time monitoring, and adaptive control systems further enhances the capabilities of these machines, making them indispensable tools in the semiconductor manufacturing process. Overall, the global laser processing machine for IC substrates market plays a crucial role in the production of high-performance semiconductor devices, supporting the ongoing advancements in electronics and technology.

| Report Metric | Details |

| Report Name | Laser Processing Machine for IC Substrates Market |

| Accounted market size in 2023 | US$ 86 million |

| Forecasted market size in 2030 | US$ 119.7 million |

| CAGR | 4.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | LPKF, Via Mechanics, MKS (ESI), Tongtai Machine & Tool, Orbotech (KLA), ADTEC, SCREEN, Chime Ball Technology, ORC Manufacturing, Ofuna Technology Co., Ltd., Schmoll Maschinen, Manz AG, Circuit Fabology Microelectronics Equipment Co.,Ltd., TZTEK Company, Han's Laser, Jiangsu Yingsu IC Equipment, HGLaser Engineering, Vega Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |