What is Global Plasticized PVC Compound Market?

The Global Plasticized PVC Compound Market refers to the worldwide industry focused on the production and distribution of plasticized polyvinyl chloride (PVC) compounds. These compounds are essentially PVC materials that have been softened by the addition of plasticizers, making them more flexible and easier to work with. This flexibility makes plasticized PVC compounds highly versatile and suitable for a wide range of applications across various industries. From construction and automotive to healthcare and consumer goods, these compounds are used in products like pipes, cables, medical devices, and packaging materials. The market is driven by the demand for durable, cost-effective, and adaptable materials that can meet the specific needs of different applications. As industries continue to innovate and expand, the global plasticized PVC compound market is expected to grow, offering new opportunities for manufacturers and suppliers.

Industrial Grade, Food Grade, Medical Grade in the Global Plasticized PVC Compound Market:

In the Global Plasticized PVC Compound Market, there are different grades of PVC compounds tailored to meet specific industry requirements: Industrial Grade, Food Grade, and Medical Grade. Industrial Grade plasticized PVC compounds are designed for applications that require durability and resistance to harsh environmental conditions. These compounds are commonly used in the construction industry for products like pipes, fittings, and profiles, as well as in the automotive sector for components such as gaskets and seals. The flexibility and toughness of industrial-grade PVC make it ideal for heavy-duty applications where mechanical strength and longevity are crucial. Food Grade plasticized PVC compounds, on the other hand, are formulated to meet stringent safety and hygiene standards required for food contact applications. These compounds are used in the production of items like food packaging, conveyor belts in food processing plants, and tubing for beverage dispensing systems. The key characteristics of food-grade PVC include non-toxicity, resistance to contamination, and the ability to withstand various temperatures without degrading. These properties ensure that the materials do not compromise the safety or quality of the food products they come into contact with. Medical Grade plasticized PVC compounds are specifically engineered to meet the rigorous standards of the healthcare industry. These compounds are used in the manufacturing of medical devices such as IV bags, tubing, catheters, and blood bags. Medical-grade PVC must be biocompatible, meaning it should not cause any adverse reactions when in contact with human tissues or fluids. Additionally, these compounds need to be sterilizable, either through autoclaving, gamma radiation, or ethylene oxide gas, to ensure they remain free from harmful microorganisms. The flexibility, clarity, and chemical resistance of medical-grade PVC make it a preferred choice for various medical applications. Each of these grades of plasticized PVC compounds plays a vital role in their respective industries by providing tailored solutions that meet specific regulatory and performance requirements. The ability to customize the properties of PVC through the use of different plasticizers and additives allows manufacturers to produce compounds that are perfectly suited for their intended applications. This versatility is one of the key factors driving the growth and adoption of plasticized PVC compounds across multiple sectors.

Pipe & Fitting, Profiles & Tubes, Wire & Cable, Film & Sheet, Other in the Global Plasticized PVC Compound Market:

The usage of Global Plasticized PVC Compound Market spans several key areas, including Pipe & Fitting, Profiles & Tubes, Wire & Cable, Film & Sheet, and other miscellaneous applications. In the Pipe & Fitting sector, plasticized PVC compounds are extensively used due to their excellent durability, flexibility, and resistance to corrosion. These properties make them ideal for plumbing, irrigation, and sewage systems where long-lasting and reliable materials are essential. The flexibility of plasticized PVC allows for easier installation and reduces the risk of leaks and breaks, which is crucial for maintaining the integrity of piping systems. In the Profiles & Tubes segment, plasticized PVC compounds are used to manufacture a variety of products such as window and door profiles, weatherstripping, and tubing for various industrial applications. The adaptability of PVC compounds allows for the production of profiles and tubes in different shapes and sizes, catering to the specific needs of different industries. The weather resistance and durability of plasticized PVC make it a preferred material for outdoor applications, ensuring that the products can withstand harsh environmental conditions without degrading. The Wire & Cable industry also benefits significantly from the use of plasticized PVC compounds. These compounds are used as insulation and jacketing materials for electrical wires and cables, providing excellent electrical insulation, flexibility, and resistance to fire and chemicals. The ability to withstand high temperatures and mechanical stress makes plasticized PVC an ideal choice for both residential and industrial wiring applications. Additionally, the flexibility of PVC compounds allows for easier handling and installation of wires and cables, reducing the risk of damage during the process. In the Film & Sheet sector, plasticized PVC compounds are used to produce a wide range of products, including packaging films, shrink wraps, and protective sheets. The clarity, flexibility, and strength of plasticized PVC make it suitable for packaging applications where product visibility and protection are important. The ability to create thin, yet durable films and sheets allows manufacturers to produce cost-effective packaging solutions that meet the needs of various industries, from food and beverage to electronics and consumer goods. Other applications of plasticized PVC compounds include the production of flooring, wall coverings, and automotive interiors. The versatility of PVC compounds allows for the creation of products with specific properties such as slip resistance, sound insulation, and aesthetic appeal. In the automotive industry, plasticized PVC is used for interior trim, seat covers, and dashboard components, providing a combination of durability, comfort, and design flexibility. The ability to customize the properties of PVC compounds through the use of different plasticizers and additives ensures that they can meet the diverse requirements of various applications. Overall, the usage of plasticized PVC compounds in these key areas highlights the material's versatility and adaptability. The ability to tailor the properties of PVC to meet specific needs makes it a valuable material for a wide range of industries, driving its continued growth and adoption in the global market.

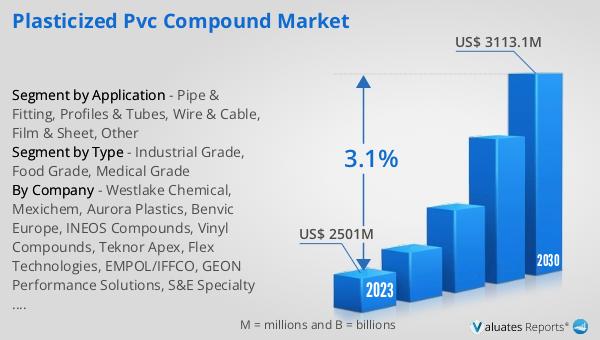

Global Plasticized PVC Compound Market Outlook:

The global Plasticized PVC Compound market was valued at US$ 2501 million in 2023 and is anticipated to reach US$ 3113.1 million by 2030, witnessing a CAGR of 3.1% during the forecast period from 2024 to 2030. This growth reflects the increasing demand for flexible and durable materials across various industries. The market's expansion is driven by the versatility of plasticized PVC compounds, which can be customized to meet the specific requirements of different applications. From construction and automotive to healthcare and consumer goods, the adaptability of plasticized PVC compounds makes them a preferred choice for manufacturers looking for cost-effective and reliable materials. As industries continue to innovate and develop new products, the demand for plasticized PVC compounds is expected to rise, contributing to the market's steady growth. The ability to produce materials that are both flexible and durable ensures that plasticized PVC compounds will remain a key component in various industrial and consumer applications.

| Report Metric | Details |

| Report Name | Plasticized PVC Compound Market |

| Accounted market size in 2023 | US$ 2501 million |

| Forecasted market size in 2030 | US$ 3113.1 million |

| CAGR | 3.1% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Westlake Chemical, Mexichem, Aurora Plastics, Benvic Europe, INEOS Compounds, Vinyl Compounds, Teknor Apex, Flex Technologies, EMPOL/IFFCO, GEON Performance Solutions, S&E Specialty Polymers, Sylvin Technologies, Konnark Polymer, Mazda Plastic, Thevinyl, ACTEGA, Avient Corporation, Hanwha, Kingfa, Thai Plastics |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |