What is Global Photomask Processing Equipment Market?

The Global Photomask Processing Equipment Market refers to the industry that manufactures and supplies equipment used in the creation and maintenance of photomasks. Photomasks are essential tools in the semiconductor and electronics industries, acting as templates for transferring circuit patterns onto semiconductor wafers. This market encompasses a variety of equipment types, including those used for direct write lithography, electron beam lithography, photomask cleaning, etching, and inspection. The demand for photomask processing equipment is driven by the continuous advancements in semiconductor technology, which require increasingly precise and complex photomasks. As technology evolves, the need for high-quality photomasks becomes more critical, pushing the market to innovate and improve the efficiency and accuracy of its equipment. The global photomask processing equipment market is a vital component of the broader semiconductor manufacturing industry, supporting the production of integrated circuits, displays, and other electronic components.

Direct Write Lithography (DLW), Electron Beam Lithography System (EBL), Photomask Cleaning Equipment, Photomask Etching Equipment, Photomask Inspection System in the Global Photomask Processing Equipment Market:

Direct Write Lithography (DLW) is a technique used in the photomask processing equipment market that allows for the direct writing of patterns onto a substrate without the need for a photomask. This method is highly flexible and can be used for rapid prototyping and small-scale production. Electron Beam Lithography System (EBL) is another advanced technology that uses a focused beam of electrons to create extremely fine patterns on a substrate. EBL is known for its high resolution and precision, making it ideal for creating complex and detailed photomasks. Photomask Cleaning Equipment is essential for maintaining the quality and longevity of photomasks. This equipment removes contaminants and particles that can affect the accuracy of the photomask during the lithography process. Photomask Etching Equipment is used to etch patterns onto the photomask, typically using chemical or plasma processes. This equipment must be highly precise to ensure that the patterns are accurately transferred onto the photomask. Photomask Inspection System is crucial for ensuring the quality and accuracy of photomasks. This system uses various techniques, such as optical and electron microscopy, to detect defects and ensure that the photomask meets the required specifications. Each of these equipment types plays a critical role in the photomask processing equipment market, contributing to the production of high-quality photomasks that are essential for the semiconductor and electronics industries.

Semiconductor/IC Photomask, Display/LCD Photomask, OLED/PCB Photomask, Others in the Global Photomask Processing Equipment Market:

The usage of Global Photomask Processing Equipment Market spans several key areas, including Semiconductor/IC Photomask, Display/LCD Photomask, OLED/PCB Photomask, and others. In the Semiconductor/IC Photomask area, photomask processing equipment is used to create the intricate patterns required for integrated circuits. These circuits are the building blocks of all modern electronic devices, and the precision of the photomasks directly impacts the performance and reliability of the final products. In the Display/LCD Photomask area, photomask processing equipment is used to produce the photomasks needed for liquid crystal displays (LCDs). These displays are used in a wide range of devices, from televisions and computer monitors to smartphones and tablets. The quality of the photomasks affects the clarity and resolution of the displays, making high-quality photomask processing equipment essential. In the OLED/PCB Photomask area, photomask processing equipment is used to create photomasks for organic light-emitting diode (OLED) displays and printed circuit boards (PCBs). OLED displays are known for their vibrant colors and high contrast ratios, and the precision of the photomasks is crucial for achieving these characteristics. PCBs are used in virtually all electronic devices, and the accuracy of the photomasks affects the performance and reliability of the circuits. Other areas where photomask processing equipment is used include the production of microelectromechanical systems (MEMS), sensors, and other advanced electronic components. In each of these areas, the quality and precision of the photomasks are critical for the performance and reliability of the final products, making photomask processing equipment an essential part of the manufacturing process.

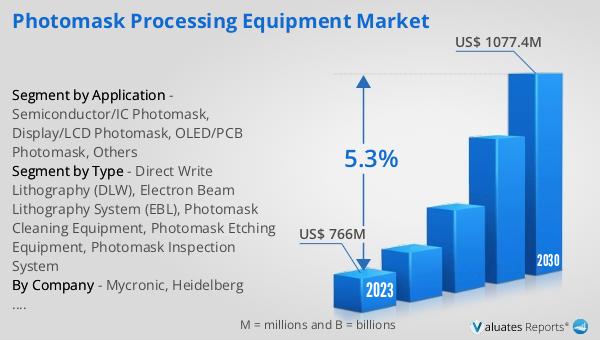

Global Photomask Processing Equipment Market Outlook:

The global Photomask Processing Equipment market was valued at US$ 766 million in 2023 and is anticipated to reach US$ 1077.4 million by 2030, witnessing a CAGR of 5.3% during the forecast period 2024-2030. This growth reflects the increasing demand for high-quality photomasks driven by advancements in semiconductor and electronics technology. As the complexity and precision of electronic devices continue to evolve, the need for advanced photomask processing equipment becomes more critical. The market's growth is also supported by the continuous innovation and development of new technologies in the photomask processing equipment industry. These advancements enable manufacturers to produce more accurate and reliable photomasks, which are essential for the production of high-performance electronic components. The increasing adoption of photomask processing equipment in various applications, such as semiconductor manufacturing, display production, and PCB fabrication, further drives the market's growth. Overall, the global photomask processing equipment market is expected to experience significant growth in the coming years, driven by the ongoing advancements in technology and the increasing demand for high-quality photomasks.

| Report Metric | Details |

| Report Name | Photomask Processing Equipment Market |

| Accounted market size in 2023 | US$ 766 million |

| Forecasted market size in 2030 | US$ 1077.4 million |

| CAGR | 5.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Mycronic, Heidelberg Instruments, JEOL, Advantest, Elionix Inc., Vistec Electron Beam GmbH, Veeco, NuFlare Technology, Inc., SÜSS MicroTec SE, Orbotech (KLA), SHIBAURA MECHATRONICS, V-Technology, ZEISS Group, Lasertec Corporation, SINTO S-PRECISION, ASML(HMI), Applied Materials, Technovision, Amaya CO., LTD, Micro Engineering Inc, Ulvac, Circuit Fabology Microelectronics Equipment Co.,Ltd., Jiangsu Yingsu IC Equipment, Beijing Hualin Jiaye |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |