What is Global Urea Control Valve Market?

The Global Urea Control Valve Market is a specialized segment within the broader industrial valve market, focusing on the regulation and control of urea flow in various industrial applications. Urea control valves are essential components in systems that handle urea, a compound widely used in agricultural fertilizers and industrial processes. These valves ensure precise control over the flow rate, pressure, and temperature of urea, which is crucial for maintaining the efficiency and safety of the processes they are involved in. The market for urea control valves is driven by the increasing demand for urea in agriculture, where it is used as a nitrogen-release fertilizer, and in industrial applications such as the production of resins, plastics, and pharmaceuticals. Additionally, the growing emphasis on reducing nitrogen oxide emissions in the automotive industry has led to the adoption of urea-based selective catalytic reduction (SCR) systems, further boosting the demand for urea control valves. The market is characterized by a variety of valve types, including straight type, angle type, and piston type, each designed to meet specific application requirements. Technological advancements and the need for efficient and reliable control systems are expected to drive the growth of the global urea control valve market in the coming years.

Straight Type, Angle Type, Piston Type in the Global Urea Control Valve Market:

In the Global Urea Control Valve Market, there are several types of valves, each designed to meet specific needs and applications. The straight type urea control valve is one of the most commonly used types. It features a straightforward design that allows for easy installation and maintenance. This type of valve is typically used in applications where the flow of urea needs to be controlled in a linear path. Its simple design makes it highly reliable and efficient, ensuring consistent performance in various industrial processes. The angle type urea control valve, on the other hand, is designed to change the direction of the flow. This type of valve is particularly useful in applications where space is limited or where the flow needs to be redirected to different parts of the system. The angle type valve is known for its durability and ability to handle high-pressure and high-temperature conditions, making it suitable for demanding industrial environments. The piston type urea control valve is another important variant in the market. This type of valve uses a piston mechanism to regulate the flow of urea. The piston moves up and down within the valve body, allowing for precise control over the flow rate. Piston type valves are known for their accuracy and reliability, making them ideal for applications that require precise flow control. They are often used in systems where the flow of urea needs to be adjusted frequently or where precise dosing is required. Each of these valve types plays a crucial role in the efficient and safe operation of urea handling systems, and their selection depends on the specific requirements of the application.

Urea reactor, Strippers, Condenser, Others in the Global Urea Control Valve Market:

The Global Urea Control Valve Market finds its usage in various critical areas, including urea reactors, strippers, condensers, and other related equipment. In urea reactors, these control valves are essential for maintaining the optimal flow and pressure of urea, which is crucial for the efficient production of urea-based products. The precise control provided by these valves ensures that the chemical reactions within the reactor occur under the right conditions, leading to higher yields and better product quality. In strippers, urea control valves play a vital role in separating urea from other components. These valves regulate the flow of urea into the stripper, ensuring that the separation process is efficient and effective. By maintaining the correct flow rate and pressure, these valves help in achieving the desired purity levels of urea, which is essential for its subsequent use in various applications. Condensers, which are used to condense urea vapors into liquid form, also rely on urea control valves for optimal performance. These valves control the flow of urea vapors into the condenser, ensuring that the condensation process occurs efficiently. By maintaining the right flow rate and pressure, these valves help in maximizing the efficiency of the condenser, leading to better energy utilization and reduced operational costs. Apart from these specific applications, urea control valves are also used in other related equipment and processes where precise control over the flow of urea is required. This includes applications in the automotive industry, where urea-based selective catalytic reduction (SCR) systems are used to reduce nitrogen oxide emissions. In such systems, urea control valves ensure the accurate dosing of urea, leading to effective emission control and compliance with environmental regulations. Overall, the usage of urea control valves in these critical areas highlights their importance in ensuring the efficient and safe operation of urea handling systems.

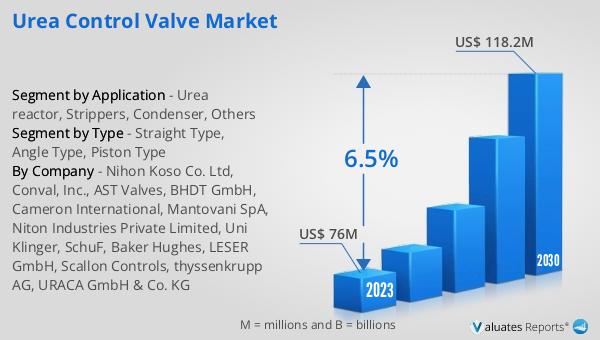

Global Urea Control Valve Market Outlook:

The global Urea Control Valve market was valued at US$ 76 million in 2023 and is anticipated to reach US$ 118.2 million by 2030, witnessing a CAGR of 6.5% during the forecast period 2024-2030. This market outlook indicates a robust growth trajectory driven by increasing demand for urea in various industrial applications. The significant growth rate underscores the expanding use of urea control valves in sectors such as agriculture, automotive, and industrial manufacturing. The rising need for efficient and reliable control systems in urea handling processes is a key factor contributing to this growth. Additionally, technological advancements in valve design and materials are expected to enhance the performance and durability of urea control valves, further driving market expansion. The projected growth also reflects the growing emphasis on environmental sustainability, with urea-based selective catalytic reduction (SCR) systems being increasingly adopted to reduce nitrogen oxide emissions in the automotive industry. As industries continue to seek ways to improve efficiency and comply with environmental regulations, the demand for advanced urea control valves is expected to rise, supporting the market's positive outlook.

| Report Metric | Details |

| Report Name | Urea Control Valve Market |

| Accounted market size in 2023 | US$ 76 million |

| Forecasted market size in 2030 | US$ 118.2 million |

| CAGR | 6.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Nihon Koso Co. Ltd, Conval, Inc., AST Valves, BHDT GmbH, Cameron International, Mantovani SpA, Niton Industries Private Limited, Uni Klinger, SchuF, Baker Hughes, LESER GmbH, Scallon Controls, thyssenkrupp AG, URACA GmbH & Co. KG |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |