What is Global Ceramic Substrate Production Systems Market?

The Global Ceramic Substrate Production Systems Market is a specialized sector within the broader electronics and materials industry. Ceramic substrates are essential components used in various electronic devices due to their excellent thermal conductivity, electrical insulation, and mechanical strength. These substrates serve as the foundation for mounting electronic circuits and components, making them crucial in the manufacturing of high-performance electronic devices. The market for ceramic substrate production systems encompasses a range of equipment and technologies designed to produce these substrates efficiently and with high precision. This includes machinery for drilling, cutting, stacking, lamination, and printing, among other processes. The demand for ceramic substrates is driven by their application in industries such as telecommunications, automotive, aerospace, and consumer electronics, where reliability and performance are paramount. As technology advances and the need for miniaturization and enhanced performance in electronic devices grows, the market for ceramic substrate production systems is expected to expand, driven by innovations and increasing adoption across various sectors.

Drilling/Cutting Machine (for Green Sheet), Stacking/Lamination Equipment (for Green Sheet), Printing Equipment, Others in the Global Ceramic Substrate Production Systems Market:

Drilling/Cutting Machines for Green Sheets are integral to the production of ceramic substrates. These machines are designed to precisely drill and cut green sheets, which are thin layers of ceramic material in their unfired state. The accuracy of these machines ensures that the substrates meet the stringent specifications required for high-performance electronic applications. Stacking/Lamination Equipment for Green Sheets is another critical component in the production process. This equipment is used to stack multiple layers of green sheets and laminate them together, forming a multi-layered ceramic substrate. The lamination process is crucial for creating substrates with complex circuit patterns and enhanced functionality. Printing Equipment plays a vital role in the production of ceramic substrates by applying conductive, resistive, and dielectric inks onto the green sheets. This step is essential for creating the intricate circuit patterns that are necessary for the operation of electronic devices. The precision and quality of the printing process directly impact the performance and reliability of the final product. Other equipment used in the production of ceramic substrates includes sintering furnaces, which are used to fire the laminated green sheets at high temperatures, transforming them into solid ceramic substrates. Quality control and inspection systems are also essential to ensure that the substrates meet the required standards and specifications. The integration of advanced technologies such as automation, robotics, and artificial intelligence in these production systems has further enhanced their efficiency and precision, enabling manufacturers to meet the growing demand for high-quality ceramic substrates.

HTCC/LTCC, DBC/DPC/AMB/AMB, Others in the Global Ceramic Substrate Production Systems Market:

The Global Ceramic Substrate Production Systems Market finds extensive usage in various applications, including HTCC (High-Temperature Co-fired Ceramic), LTCC (Low-Temperature Co-fired Ceramic), DBC (Direct Bonded Copper), DPC (Direct Plated Copper), AMB (Active Metal Brazed), and others. HTCC and LTCC are widely used in the production of electronic components that require high thermal stability and reliability. HTCC substrates are typically used in high-temperature environments, such as automotive and aerospace applications, where they provide excellent thermal management and mechanical strength. LTCC substrates, on the other hand, are used in applications that require lower processing temperatures, such as telecommunications and consumer electronics. DBC, DPC, and AMB substrates are used in power electronics and high-frequency applications. DBC substrates consist of a ceramic layer bonded to a copper layer, providing excellent thermal conductivity and electrical insulation. They are commonly used in power modules, inverters, and other high-power electronic devices. DPC substrates are similar to DBC substrates but use a different bonding process, resulting in improved thermal performance and reliability. AMB substrates are used in applications that require high thermal conductivity and mechanical strength, such as power electronics and LED lighting. Other applications of ceramic substrates include sensors, actuators, and medical devices, where their unique properties make them ideal for use in harsh environments and demanding applications. The versatility and performance of ceramic substrates make them a critical component in the development of advanced electronic devices, driving the demand for production systems that can deliver high-quality substrates with precision and efficiency.

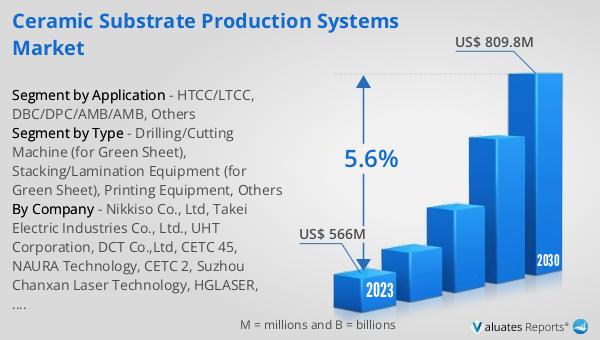

Global Ceramic Substrate Production Systems Market Outlook:

The global Ceramic Substrate Production Systems market was valued at US$ 566 million in 2023 and is anticipated to reach US$ 809.8 million by 2030, witnessing a CAGR of 5.6% during the forecast period 2024-2030. This growth is driven by the increasing demand for high-performance electronic devices across various industries, including telecommunications, automotive, aerospace, and consumer electronics. The advancements in technology and the need for miniaturization and enhanced performance in electronic devices are also contributing to the growth of the market. The integration of advanced technologies such as automation, robotics, and artificial intelligence in production systems has further enhanced their efficiency and precision, enabling manufacturers to meet the growing demand for high-quality ceramic substrates. As the market continues to evolve, manufacturers are focusing on developing innovative solutions that can deliver superior performance and reliability, driving the adoption of ceramic substrate production systems across various sectors.

| Report Metric | Details |

| Report Name | Ceramic Substrate Production Systems Market |

| Accounted market size in 2023 | US$ 566 million |

| Forecasted market size in 2030 | US$ 809.8 million |

| CAGR | 5.6% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Nikkiso Co., Ltd, Takei Electric Industries Co., Ltd., UHT Corporation, DCT Co.,Ltd, CETC 45, NAURA Technology, CETC 2, Suzhou Chanxan Laser Technology, HGLASER, Hefei Facerom |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |