What is Global Wafer AOI System Market?

The Global Wafer AOI (Automated Optical Inspection) System Market is a specialized segment within the semiconductor industry that focuses on the inspection of wafers during the manufacturing process. These systems are designed to detect defects and ensure the quality of wafers, which are thin slices of semiconductor material used in the production of integrated circuits and other microdevices. The market for wafer AOI systems is driven by the increasing demand for high-quality semiconductor devices, which are essential for various applications such as consumer electronics, automotive, telecommunications, and industrial automation. The adoption of advanced technologies like AI and machine learning in AOI systems has further enhanced their accuracy and efficiency, making them indispensable in modern semiconductor manufacturing. As the semiconductor industry continues to grow, the demand for wafer AOI systems is expected to rise, driven by the need for higher yields and improved product quality.

300mm AOI Wafer Inspection Equipment, 200mm AOI Wafer Inspection Equipment, 150mm AOI Wafer Inspection Equipment in the Global Wafer AOI System Market:

300mm AOI Wafer Inspection Equipment is a critical component in the Global Wafer AOI System Market, primarily used for inspecting larger wafers that are 300 millimeters in diameter. These larger wafers are increasingly popular in the semiconductor industry due to their ability to produce more chips per wafer, thereby reducing manufacturing costs. The 300mm AOI systems are equipped with advanced imaging and analysis technologies that can detect even the smallest defects, ensuring the highest quality standards are met. On the other hand, 200mm AOI Wafer Inspection Equipment is used for inspecting wafers that are 200 millimeters in diameter. While not as large as the 300mm wafers, 200mm wafers are still widely used in the industry, particularly for the production of analog devices, power semiconductors, and MEMS (Micro-Electro-Mechanical Systems). The 200mm AOI systems are designed to provide high-resolution imaging and precise defect detection, making them essential for maintaining product quality. Lastly, 150mm AOI Wafer Inspection Equipment is used for inspecting wafers that are 150 millimeters in diameter. These smaller wafers are typically used in niche applications and older semiconductor manufacturing processes. Despite their smaller size, the 150mm AOI systems are equipped with sophisticated inspection technologies to ensure that even the smallest defects are identified and addressed. Overall, the different sizes of AOI wafer inspection equipment cater to the diverse needs of the semiconductor industry, ensuring that wafers of all sizes meet the stringent quality standards required for modern electronic devices.

Advanced Packaging, MEMS or Microfluidic, LED, Laser/VCSEL, Others in the Global Wafer AOI System Market:

The usage of Global Wafer AOI System Market spans across various applications, including Advanced Packaging, MEMS or Microfluidic, LED, Laser/VCSEL, and others. In Advanced Packaging, wafer AOI systems play a crucial role in inspecting the intricate structures and interconnections that are essential for high-performance semiconductor devices. These systems ensure that the packaging process is free from defects, thereby enhancing the reliability and performance of the final product. In the realm of MEMS or Microfluidic devices, wafer AOI systems are used to inspect the tiny mechanical and fluidic structures that are critical for the functionality of these devices. The high-resolution imaging capabilities of AOI systems enable the detection of minute defects that could impact the performance of MEMS and microfluidic devices. For LED manufacturing, wafer AOI systems are employed to inspect the epitaxial layers and other critical structures to ensure that the LEDs meet the required brightness and efficiency standards. The ability to detect defects early in the manufacturing process helps in reducing waste and improving yield. In the case of Laser/VCSEL (Vertical-Cavity Surface-Emitting Laser) devices, wafer AOI systems are used to inspect the laser structures and ensure that they meet the stringent quality requirements for applications such as data communication and sensing. The high precision and accuracy of AOI systems are essential for maintaining the performance and reliability of Laser/VCSEL devices. Additionally, wafer AOI systems are used in other applications such as power semiconductors, analog devices, and RF (Radio Frequency) components, where the detection of defects is critical for ensuring the performance and reliability of the final product. Overall, the usage of wafer AOI systems across these diverse applications highlights their importance in maintaining the quality and performance of modern semiconductor devices.

Global Wafer AOI System Market Outlook:

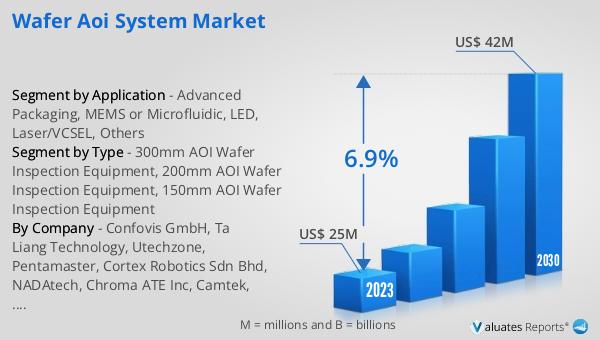

The global Wafer AOI System market was valued at US$ 25 million in 2023 and is anticipated to reach US$ 42 million by 2030, witnessing a CAGR of 6.9% during the forecast period 2024-2030. This growth is driven by the increasing demand for high-quality semiconductor devices across various industries, including consumer electronics, automotive, telecommunications, and industrial automation. The adoption of advanced technologies such as AI and machine learning in AOI systems has further enhanced their accuracy and efficiency, making them indispensable in modern semiconductor manufacturing. As the semiconductor industry continues to grow, the demand for wafer AOI systems is expected to rise, driven by the need for higher yields and improved product quality. The market outlook for wafer AOI systems is positive, with significant growth opportunities in the coming years. The increasing complexity of semiconductor devices and the need for stringent quality control measures are expected to drive the adoption of wafer AOI systems across various applications. Additionally, the ongoing advancements in AOI technology, such as the development of high-resolution imaging and advanced defect detection algorithms, are expected to further boost the market growth. Overall, the global Wafer AOI System market is poised for significant growth, driven by the increasing demand for high-quality semiconductor devices and the continuous advancements in AOI technology.

| Report Metric | Details |

| Report Name | Wafer AOI System Market |

| Accounted market size in 2023 | US$ 25 million |

| Forecasted market size in 2030 | US$ 42 million |

| CAGR | 6.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Confovis GmbH, Ta Liang Technology, Utechzone, Pentamaster, Cortex Robotics Sdn Bhd, NADAtech, Chroma ATE Inc, Camtek, TAKAOKA TOKO, Intekplus, Machine Vision Products, Inc., SMEE, PEMTRON, Hangzhou Changchuan Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |