What is Global Photomask Production Equipment Market?

The Global Photomask Production Equipment Market refers to the industry that manufactures and supplies equipment used to produce photomasks. Photomasks are essential tools in the semiconductor and electronics industries, serving as templates for transferring circuit patterns onto semiconductor wafers, flat panel displays, and other substrates. This market encompasses a variety of equipment types, including mask aligners, direct write lithography systems, and electron beam lithography systems, among others. The demand for photomask production equipment is driven by the continuous advancements in semiconductor technology, the increasing complexity of integrated circuits, and the growing need for high-resolution displays. As technology evolves, the precision and capabilities of photomask production equipment must also advance to meet the stringent requirements of modern electronics manufacturing. This market is critical for enabling the production of cutting-edge electronic devices, from smartphones and computers to advanced medical equipment and automotive electronics.

Direct Write Lithography (DLW), Electron Beam Lithography System (EBL) in the Global Photomask Production Equipment Market:

Direct Write Lithography (DLW) and Electron Beam Lithography System (EBL) are two advanced technologies used in the Global Photomask Production Equipment Market. DLW is a maskless lithography technique that directly writes patterns onto a substrate using a focused beam of light or electrons. This method is highly flexible and allows for rapid prototyping and small-scale production without the need for a physical photomask. DLW is particularly useful for research and development applications, where quick iterations and modifications are required. On the other hand, Electron Beam Lithography System (EBL) uses a focused beam of electrons to create extremely fine patterns on a substrate. EBL is known for its high resolution and precision, making it ideal for producing photomasks with intricate and detailed designs. This technology is widely used in the semiconductor industry for fabricating advanced integrated circuits and nanostructures. Both DLW and EBL play crucial roles in the photomask production process, offering unique advantages in terms of flexibility, resolution, and precision. As the demand for smaller and more complex electronic devices continues to grow, the importance of these technologies in the photomask production equipment market is expected to increase. The ability to produce high-quality photomasks with fine details and accurate patterns is essential for the advancement of semiconductor technology and the development of next-generation electronic devices.

Semiconductor/IC, Display/LCD, OLED/PCB, Others in the Global Photomask Production Equipment Market:

The usage of Global Photomask Production Equipment Market spans several key areas, including Semiconductor/IC, Display/LCD, OLED/PCB, and others. In the Semiconductor/IC sector, photomask production equipment is vital for the fabrication of integrated circuits. Photomasks serve as templates for transferring intricate circuit patterns onto semiconductor wafers, enabling the production of microchips used in a wide range of electronic devices. The precision and accuracy of photomasks are crucial for ensuring the performance and reliability of these microchips. In the Display/LCD sector, photomask production equipment is used to create masks for manufacturing liquid crystal displays (LCDs). These displays are commonly found in televisions, computer monitors, and mobile devices. The quality of the photomasks directly impacts the resolution and clarity of the displays, making advanced photomask production equipment essential for producing high-definition screens. In the OLED/PCB sector, photomask production equipment is used to produce masks for organic light-emitting diode (OLED) displays and printed circuit boards (PCBs). OLED displays are known for their vibrant colors and energy efficiency, and high-quality photomasks are necessary for achieving these characteristics. PCBs, which serve as the backbone of electronic devices, require precise photomasks to ensure accurate circuit patterns and reliable performance. Additionally, photomask production equipment is used in other areas such as microelectromechanical systems (MEMS), photonics, and biotechnology. In these fields, photomasks are used to create intricate patterns and structures for various applications, from sensors and actuators to optical components and medical devices. The versatility and precision of photomask production equipment make it indispensable for a wide range of industries, driving innovation and enabling the development of advanced technologies.

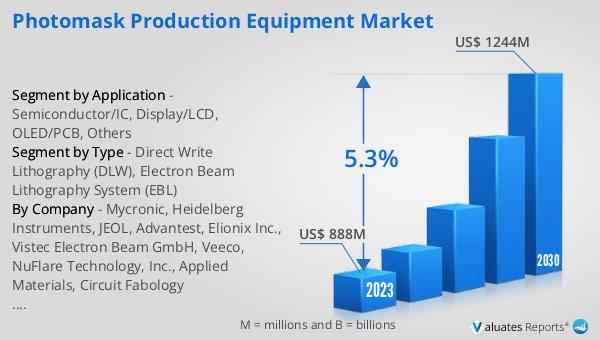

Global Photomask Production Equipment Market Outlook:

The global Photomask Production Equipment market was valued at US$ 888 million in 2023 and is anticipated to reach US$ 1244 million by 2030, witnessing a CAGR of 5.3% during the forecast period 2024-2030. This market outlook highlights the steady growth and increasing demand for photomask production equipment over the coming years. The projected growth rate reflects the continuous advancements in semiconductor technology, the rising complexity of integrated circuits, and the expanding applications of photomasks in various industries. As electronic devices become more sophisticated and miniaturized, the need for high-precision photomasks and advanced production equipment becomes even more critical. The market's growth is also driven by the increasing adoption of advanced display technologies, such as OLED and high-resolution LCDs, which require high-quality photomasks for their production. Furthermore, the ongoing research and development activities in nanotechnology and biotechnology are expected to create new opportunities for photomask production equipment. The ability to produce photomasks with fine details and accurate patterns is essential for the advancement of these cutting-edge technologies. Overall, the global Photomask Production Equipment market is poised for significant growth, driven by technological advancements and the expanding applications of photomasks in various industries.

| Report Metric | Details |

| Report Name | Photomask Production Equipment Market |

| Accounted market size in 2023 | US$ 888 million |

| Forecasted market size in 2030 | US$ 1244 million |

| CAGR | 5.3% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Mycronic, Heidelberg Instruments, JEOL, Advantest, Elionix Inc., Vistec Electron Beam GmbH, Veeco, NuFlare Technology, Inc., Applied Materials, Circuit Fabology Microelectronics Equipment Co.,Ltd., Jiangsu Yingsu IC Equipment |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |