What is Global Production Equipment for IC Substrate Market?

The Global Production Equipment for IC Substrate Market refers to the industry that manufactures and supplies machinery and tools used in the production of IC (Integrated Circuit) substrates. IC substrates are essential components in semiconductor devices, acting as the base on which ICs are built. These substrates provide mechanical support and electrical connections for the ICs. The market for production equipment includes a wide range of machinery such as direct imaging exposure systems, drilling machines, automated optical inspection systems, routing machines, automated vision inspection systems, ABF film laminators, VCP equipment, flying probe testers, and PTH (plated through-hole) machines. These machines are crucial for ensuring the precision, efficiency, and quality of IC substrates, which are used in various electronic devices like smartphones, computers, and other digital gadgets. The demand for advanced production equipment is driven by the growing need for high-performance electronic devices and the continuous advancements in semiconductor technology.

Direct Imaging Exposure System/LDI, Drilling Machine for IC Substrate, Automated Optical Inspection (AOI) for IC Substrate, Routing Machine for IC Substrate, Automated Vision Inspection (AVI) for IC Substrate, ABF Film Laminator, VCP Equipment, Flying Probe Tester, PTH, Others in the Global Production Equipment for IC Substrate Market:

Direct Imaging Exposure System/LDI (Laser Direct Imaging) is a critical piece of equipment in the IC substrate production process. It uses laser technology to directly image the circuit patterns onto the substrate, ensuring high precision and accuracy. This system is essential for creating fine lines and spaces required in modern IC designs. Drilling Machines for IC Substrates are used to create holes or vias in the substrate, which are necessary for electrical connections between different layers of the circuit. These machines must be highly accurate to ensure the proper alignment and size of the holes. Automated Optical Inspection (AOI) systems are used to inspect the substrates for defects such as misalignments, scratches, or other imperfections. AOI systems use cameras and image processing software to detect these defects quickly and accurately, ensuring high-quality production. Routing Machines for IC Substrates are used to cut and shape the substrates into the desired dimensions. These machines must be precise to ensure that the substrates fit perfectly into the final electronic devices. Automated Vision Inspection (AVI) systems are similar to AOI systems but are used for final inspection after all other processes are completed. They ensure that the finished substrates meet all quality standards before being shipped to customers. ABF Film Laminators are used to apply ABF (Ajinomoto Build-up Film) to the substrates. ABF is a crucial material that provides insulation and mechanical support to the ICs. VCP (Vertical Continuous Plating) Equipment is used for plating the substrates with metals such as copper, which are necessary for electrical conductivity. Flying Probe Testers are used to test the electrical connections on the substrates. They use probes to make contact with the circuit and measure electrical properties to ensure proper functionality. PTH (Plated Through-Hole) machines are used to create and plate through-holes in the substrates, which are necessary for electrical connections between different layers. Other equipment in the IC substrate production market includes various types of machinery and tools that support the overall production process, ensuring efficiency, precision, and high quality.

FC-BGA (ABF), FC-CSP, BGA/CSP, SiP and RF Modules, Others in the Global Production Equipment for IC Substrate Market:

The usage of Global Production Equipment for IC Substrate Market spans several key areas, including FC-BGA (Flip Chip Ball Grid Array) with ABF (Ajinomoto Build-up Film), FC-CSP (Flip Chip Chip Scale Package), BGA/CSP (Ball Grid Array/Chip Scale Package), SiP (System in Package), and RF (Radio Frequency) Modules, among others. FC-BGA (ABF) substrates are used in high-performance computing and communication devices. The production equipment for these substrates must be highly precise and capable of handling the complex designs and fine lines required for these applications. FC-CSP substrates are used in compact electronic devices such as smartphones and tablets. The production equipment for these substrates must be capable of producing small, high-density circuits with high reliability. BGA/CSP substrates are used in a wide range of electronic devices, from consumer electronics to industrial applications. The production equipment for these substrates must be versatile and capable of handling various designs and sizes. SiP substrates are used in advanced electronic devices that integrate multiple ICs into a single package. The production equipment for these substrates must be capable of handling complex designs and ensuring high reliability and performance. RF Modules are used in wireless communication devices such as smartphones, tablets, and IoT (Internet of Things) devices. The production equipment for these substrates must be capable of producing high-frequency circuits with high precision and reliability. Other applications of IC substrates include automotive electronics, medical devices, and aerospace applications. The production equipment for these substrates must be capable of handling the specific requirements of these applications, such as high reliability, precision, and performance. Overall, the usage of Global Production Equipment for IC Substrate Market is essential for producing high-quality IC substrates that meet the demands of modern electronic devices.

Global Production Equipment for IC Substrate Market Outlook:

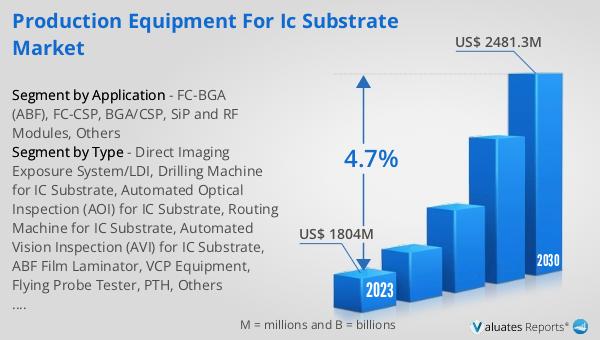

The global Production Equipment for IC Substrate market was valued at US$ 1804 million in 2023 and is anticipated to reach US$ 2481.3 million by 2030, witnessing a CAGR of 4.7% during the forecast period 2024-2030. This growth is driven by the increasing demand for advanced electronic devices and the continuous advancements in semiconductor technology. The market outlook indicates a positive trend, with significant investments in research and development to improve the efficiency and precision of production equipment. The growing adoption of IoT devices, 5G technology, and artificial intelligence is also expected to drive the demand for high-performance IC substrates, further boosting the market for production equipment. Additionally, the increasing focus on miniaturization and the need for high-density circuits in modern electronic devices are expected to drive the demand for advanced production equipment. The market is also witnessing a trend towards automation and digitalization, with manufacturers investing in automated production lines and advanced inspection systems to improve efficiency and reduce production costs. Overall, the global Production Equipment for IC Substrate market is expected to witness significant growth in the coming years, driven by the increasing demand for high-performance electronic devices and continuous advancements in semiconductor technology.

| Report Metric | Details |

| Report Name | Production Equipment for IC Substrate Market |

| Accounted market size in 2023 | US$ 1804 million |

| Forecasted market size in 2030 | US$ 2481.3 million |

| CAGR | 4.7% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Orbotech (KLA), ADTEC, SCREEN, Chime Ball Technology, ORC Manufacturing, Manz (KLEO), Ofuna Technology Co., Ltd., Symtek Automation, C SUN, AMPOC, GROUP UP Industrial (GP), Gallant Precision Machining (GPM), Eclat Forever Company, Utechzone, Ta Liang Technology, MACHVISION Inc Co., LTD, GigaVis, CIMS, Favite, FUSEI MENIX, Mycronic (atg), Circuit Fabology Microelectronics Equipment Co.,Ltd., TZTEK Company, Han's Laser, Jiangsu Yingsu IC Equipment, Kun Shan Korbe Precision Equipment, Kunshan Dongwei Technology, INSPEC, Saki Corporation, Via Mechanics, MKS (ESI), Tongtai Machine & Tool |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |