What is Global Blanking and Punching Presses Market?

The global blanking and punching presses market is a specialized segment within the broader machinery and equipment industry. Blanking and punching presses are essential tools used in manufacturing processes to cut and shape metal sheets into specific forms and sizes. These machines are widely utilized across various industries, including automotive, aerospace, shipbuilding, home appliances, and general machinery. The market for these presses is driven by the increasing demand for precision and efficiency in metalworking processes. Technological advancements have led to the development of more sophisticated and automated presses, which enhance productivity and reduce operational costs. The global market is characterized by a mix of established players and new entrants, all striving to innovate and offer better solutions to meet the evolving needs of their customers. The market's growth is also influenced by factors such as economic conditions, industrialization, and the adoption of advanced manufacturing techniques. As industries continue to seek ways to improve their production capabilities, the demand for high-quality blanking and punching presses is expected to remain strong.

Mechanical Press, Hydraulic Press in the Global Blanking and Punching Presses Market:

Mechanical presses and hydraulic presses are two primary types of machines used in the global blanking and punching presses market. Mechanical presses operate using a motor-driven flywheel that stores energy and releases it to perform the pressing action. These presses are known for their high-speed operation and are ideal for applications requiring repetitive and consistent force. They are commonly used in the automotive industry for stamping and forming metal parts. Mechanical presses are favored for their reliability, ease of maintenance, and ability to handle high-volume production runs. On the other hand, hydraulic presses use a hydraulic cylinder to generate force, allowing for greater control over the pressing process. These presses are highly versatile and can be used for a wide range of applications, including deep drawing, punching, and forming. Hydraulic presses are preferred for their ability to deliver consistent pressure and their capability to handle complex shapes and materials. They are widely used in industries such as aerospace, shipbuilding, and home appliances, where precision and flexibility are crucial. The choice between mechanical and hydraulic presses depends on various factors, including the specific requirements of the application, the type of material being processed, and the desired production speed. Both types of presses have their unique advantages and are essential tools in modern manufacturing processes.

Automotive, General Machine, Home Appliances, Aerospace & Shipbuilding in the Global Blanking and Punching Presses Market:

The global blanking and punching presses market finds extensive usage in several key industries, including automotive, general machinery, home appliances, aerospace, and shipbuilding. In the automotive industry, these presses are used to manufacture various components such as body panels, chassis parts, and engine components. The high precision and efficiency of blanking and punching presses make them ideal for producing the complex shapes and sizes required in automotive manufacturing. In the general machinery sector, these presses are used to create parts and components for various types of machinery and equipment. The ability to produce high-quality, durable parts quickly and efficiently is crucial in this industry. In the home appliances industry, blanking and punching presses are used to manufacture parts for products such as refrigerators, washing machines, and ovens. The demand for aesthetically pleasing and functional home appliances drives the need for precise and efficient manufacturing processes. In the aerospace industry, these presses are used to produce components for aircraft and spacecraft. The high standards of quality and precision required in this industry make blanking and punching presses an essential tool. In the shipbuilding industry, these presses are used to create parts for ships and other marine vessels. The ability to handle large and complex parts makes these presses ideal for this industry. Overall, the global blanking and punching presses market plays a critical role in supporting the manufacturing needs of various industries, contributing to their growth and development.

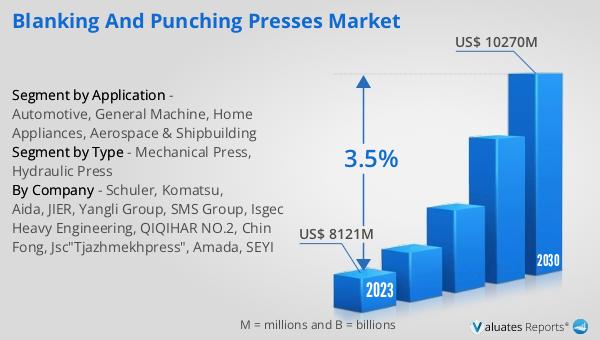

Global Blanking and Punching Presses Market Outlook:

The global blanking and punching presses market was valued at $8,121 million in 2023 and is expected to reach $10,270 million by 2030, with a compound annual growth rate (CAGR) of 3.5% during the forecast period from 2024 to 2030. This market outlook indicates a steady growth trajectory driven by the increasing demand for precision and efficiency in metalworking processes across various industries. The adoption of advanced manufacturing techniques and the need for high-quality metal components are key factors contributing to this growth. As industries continue to evolve and seek ways to enhance their production capabilities, the demand for blanking and punching presses is expected to remain robust. The market's growth is also supported by technological advancements that have led to the development of more sophisticated and automated presses, which enhance productivity and reduce operational costs. The global market is characterized by a mix of established players and new entrants, all striving to innovate and offer better solutions to meet the evolving needs of their customers. Overall, the global blanking and punching presses market is poised for significant growth in the coming years, driven by the increasing demand for high-quality metal components and the adoption of advanced manufacturing techniques.

| Report Metric | Details |

| Report Name | Blanking and Punching Presses Market |

| Accounted market size in 2023 | US$ 8121 million |

| Forecasted market size in 2030 | US$ 10270 million |

| CAGR | 3.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Schuler, Komatsu, Aida, JIER, Yangli Group, SMS Group, Isgec Heavy Engineering, QIQIHAR NO.2, Chin Fong, Jsc"Tjazhmekhpress", Amada, SEYI |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |