What is Global Non-plasticized PVC Compound Market?

The Global Non-plasticized PVC Compound Market refers to the worldwide industry focused on the production and distribution of non-plasticized polyvinyl chloride (PVC) compounds. These compounds are essentially rigid forms of PVC that do not contain plasticizers, which are substances added to plastics to increase their flexibility. Non-plasticized PVC compounds are known for their durability, chemical resistance, and rigidity, making them suitable for a variety of applications. They are widely used in industries such as construction, automotive, electrical, and healthcare due to their excellent mechanical properties and cost-effectiveness. The market for these compounds is driven by the growing demand for sustainable and durable materials in various sectors, as well as the increasing awareness of the environmental impact of plasticizers. As industries continue to seek materials that offer both performance and sustainability, the global non-plasticized PVC compound market is expected to see steady growth.

Industrial Grade, Food Grade, Medical Grade in the Global Non-plasticized PVC Compound Market:

In the Global Non-plasticized PVC Compound Market, there are several grades of PVC compounds tailored to meet the specific needs of different industries. Industrial Grade non-plasticized PVC compounds are designed for applications that require high durability and resistance to harsh environmental conditions. These compounds are commonly used in the construction industry for making pipes, fittings, and profiles due to their excellent mechanical strength and resistance to chemicals and UV radiation. They are also used in the automotive industry for manufacturing various components that need to withstand high temperatures and mechanical stress. Food Grade non-plasticized PVC compounds are formulated to meet stringent safety and hygiene standards required for food contact applications. These compounds are used in the production of food packaging materials, conveyor belts, and other equipment that comes into direct contact with food products. They are designed to be non-toxic, odorless, and resistant to oils and fats, ensuring that they do not contaminate the food. Medical Grade non-plasticized PVC compounds are developed to meet the rigorous standards of the healthcare industry. These compounds are used in the manufacturing of medical devices, tubing, and containers that require high levels of purity and biocompatibility. They are designed to be free from harmful additives and plasticizers, ensuring that they do not cause any adverse reactions when in contact with the human body. Additionally, medical grade PVC compounds are resistant to sterilization processes, making them suitable for use in various medical applications. Overall, the different grades of non-plasticized PVC compounds cater to the diverse needs of various industries, providing them with materials that offer the required performance and safety standards.

Pipe & Fitting, Profiles & Tubes, Wire & Cable, Film & Sheet, Other in the Global Non-plasticized PVC Compound Market:

The Global Non-plasticized PVC Compound Market finds extensive usage in several key areas, including Pipe & Fitting, Profiles & Tubes, Wire & Cable, Film & Sheet, and other applications. In the Pipe & Fitting sector, non-plasticized PVC compounds are highly valued for their strength, durability, and resistance to corrosion and chemicals. These properties make them ideal for use in plumbing, sewage, and irrigation systems, where long-lasting and reliable materials are essential. The rigid nature of non-plasticized PVC ensures that pipes and fittings maintain their shape and integrity under various environmental conditions, reducing the need for frequent replacements and maintenance. In the Profiles & Tubes segment, non-plasticized PVC compounds are used to manufacture a wide range of products, including window and door profiles, as well as various types of tubing. The rigidity and stability of these compounds make them suitable for structural applications, providing excellent support and insulation properties. They are also resistant to weathering and UV radiation, making them ideal for outdoor use. The Wire & Cable industry utilizes non-plasticized PVC compounds for insulation and sheathing purposes. The compounds provide excellent electrical insulation properties, ensuring the safety and reliability of electrical systems. Additionally, their resistance to chemicals and moisture makes them suitable for use in harsh environments, such as industrial settings and underground installations. In the Film & Sheet sector, non-plasticized PVC compounds are used to produce rigid films and sheets that are used in various applications, including packaging, signage, and construction. These materials offer excellent clarity, rigidity, and resistance to impact, making them suitable for protective coverings and display purposes. Other applications of non-plasticized PVC compounds include the production of flooring, automotive components, and consumer goods. The versatility and performance characteristics of these compounds make them a preferred choice for manufacturers looking for durable and cost-effective materials.

Global Non-plasticized PVC Compound Market Outlook:

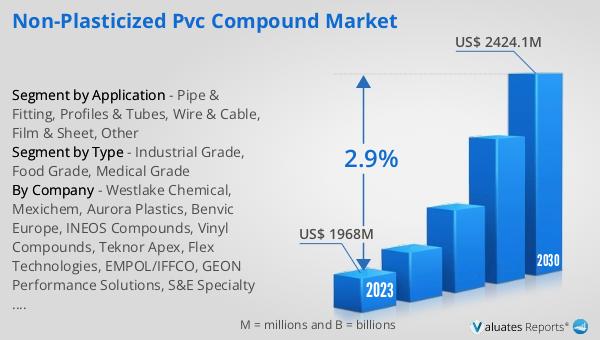

The global Non-plasticized PVC Compound market was valued at US$ 1968 million in 2023 and is anticipated to reach US$ 2424.1 million by 2030, witnessing a CAGR of 2.9% during the forecast period 2024-2030. This market outlook indicates a steady growth trajectory for non-plasticized PVC compounds, driven by the increasing demand for durable and sustainable materials across various industries. The market's growth is supported by the rising awareness of the environmental impact of plasticizers and the need for materials that offer both performance and sustainability. As industries continue to seek alternatives to traditional plasticized PVC, the demand for non-plasticized PVC compounds is expected to rise. The construction, automotive, electrical, and healthcare sectors are among the key drivers of this market, as they require materials that can withstand harsh conditions and provide long-lasting performance. The market's growth is also influenced by advancements in manufacturing technologies and the development of new formulations that enhance the properties of non-plasticized PVC compounds. Overall, the global Non-plasticized PVC Compound market is poised for steady growth, driven by the increasing demand for high-performance and environmentally friendly materials.

| Report Metric | Details |

| Report Name | Non-plasticized PVC Compound Market |

| Accounted market size in 2023 | US$ 1968 million |

| Forecasted market size in 2030 | US$ 2424.1 million |

| CAGR | 2.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Westlake Chemical, Mexichem, Aurora Plastics, Benvic Europe, INEOS Compounds, Vinyl Compounds, Teknor Apex, Flex Technologies, EMPOL/IFFCO, GEON Performance Solutions, S&E Specialty Polymers, Sylvin Technologies, Konnark Polymer, Mazda Plastic, Thevinyl, ACTEGA, Avient Corporation, Hanwha, Kingfa |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |