What is Global Ceramic Wafer End Effectors Market?

The Global Ceramic Wafer End Effectors Market refers to the industry focused on the production and distribution of ceramic wafer end effectors, which are specialized tools used in semiconductor manufacturing. These end effectors are crucial for handling delicate silicon wafers during various stages of semiconductor production, such as etching, deposition, and inspection. Made from high-performance ceramic materials, these tools offer superior thermal stability, chemical resistance, and mechanical strength compared to their metal counterparts. The market encompasses a wide range of products tailored to meet the specific needs of semiconductor manufacturers, including different types of ceramic materials and designs. As the demand for advanced electronic devices continues to grow, the need for reliable and efficient wafer handling solutions is also increasing, driving the expansion of the global ceramic wafer end effectors market.

Alumina Wafer End Effector, Silicon Carbide Wafer End Effector, Others in the Global Ceramic Wafer End Effectors Market:

Alumina wafer end effectors are one of the most commonly used types in the global ceramic wafer end effectors market. Alumina, or aluminum oxide, is known for its excellent thermal and chemical stability, making it ideal for high-temperature and corrosive environments typically found in semiconductor manufacturing. These end effectors are highly durable and can withstand repeated use without significant wear and tear, ensuring consistent performance over time. Silicon carbide wafer end effectors, on the other hand, offer even greater hardness and thermal conductivity than alumina. Silicon carbide is particularly useful in applications where extreme temperatures and mechanical stress are involved. This material's superior properties make it suitable for handling wafers in processes that require high precision and minimal contamination. Other types of ceramic wafer end effectors include those made from zirconia and other advanced ceramic materials. Zirconia end effectors are known for their exceptional toughness and resistance to cracking, making them ideal for applications where mechanical shock and impact are concerns. These various types of ceramic wafer end effectors cater to the diverse needs of the semiconductor industry, providing reliable and efficient solutions for wafer handling in different manufacturing processes.

8 inch Wafer, 12 inch Wafer in the Global Ceramic Wafer End Effectors Market:

The usage of ceramic wafer end effectors in the global market is particularly significant for handling 8-inch and 12-inch wafers, which are standard sizes in the semiconductor industry. For 8-inch wafers, ceramic end effectors offer precise handling and positioning, which is crucial for maintaining the integrity of the wafers during manufacturing processes. The high thermal stability and chemical resistance of ceramic materials ensure that the wafers are not contaminated or damaged, leading to higher yields and better-quality semiconductor devices. In the case of 12-inch wafers, the challenges are even greater due to the larger size and increased fragility of the wafers. Ceramic wafer end effectors designed for 12-inch wafers must provide even greater precision and stability to prevent breakage and contamination. The use of advanced ceramic materials such as silicon carbide and zirconia in these end effectors ensures that they can handle the increased mechanical stress and thermal demands associated with larger wafers. Overall, the use of ceramic wafer end effectors in handling 8-inch and 12-inch wafers is essential for achieving high efficiency and reliability in semiconductor manufacturing processes.

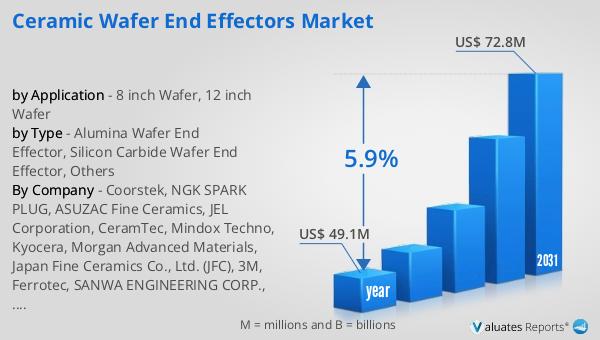

Global Ceramic Wafer End Effectors Market Outlook:

The global ceramic wafer end effectors market was valued at US$ 43 million in 2023 and is expected to grow to US$ 66 million by 2030, with a compound annual growth rate (CAGR) of 5.9% during the forecast period from 2024 to 2030. This growth is driven by the increasing demand for advanced semiconductor devices and the need for reliable and efficient wafer handling solutions in the semiconductor manufacturing industry. The superior properties of ceramic materials, such as high thermal stability, chemical resistance, and mechanical strength, make them ideal for use in wafer end effectors. As the semiconductor industry continues to evolve and advance, the demand for high-performance wafer handling tools is expected to increase, driving the growth of the global ceramic wafer end effectors market.

| Report Metric | Details |

| Report Name | Ceramic Wafer End Effectors Market |

| Accounted market size in 2023 | US$ 43 million |

| Forecasted market size in 2030 | US$ 66 million |

| CAGR | 5.9% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Coorstek, NGK SPARK PLUG, ASUZAC Fine Ceramics, JEL Corporation, CeramTec, Mindox Techno, Kyocera, Morgan Advanced Materials, Japan Fine Ceramics Co., Ltd. (JFC), 3M, Ferrotec, SANWA ENGINEERING CORP., St.Cera Co., Ltd, Shanghai Companion |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |