What is Global CCA wood preservative Market?

The Global CCA (Chromated Copper Arsenate) wood preservative market is a significant segment within the broader wood preservation industry. CCA is a chemical compound used to protect wood from decay, insects, and other deteriorating factors, extending the life of wooden structures. This market is driven by the demand for durable and long-lasting wood products, especially in regions with harsh weather conditions or high insect activity. CCA-treated wood is commonly used in various applications, including construction, agriculture, and infrastructure, due to its effectiveness in preserving wood. The market's growth is influenced by factors such as increasing construction activities, the need for sustainable building materials, and regulatory frameworks governing the use of wood preservatives. However, environmental concerns and health risks associated with CCA have led to restrictions in some regions, impacting market dynamics. Despite these challenges, the demand for CCA wood preservatives remains robust in many parts of the world, driven by the need for cost-effective and reliable wood protection solutions. As the industry evolves, manufacturers are focusing on developing safer and more environmentally friendly alternatives to traditional CCA formulations, ensuring compliance with regulatory standards while meeting consumer demands.

CCA-C, CCA-B, CCA-A in the Global CCA wood preservative Market:

CCA wood preservatives are categorized into three main types: CCA-C, CCA-B, and CCA-A, each with distinct formulations and applications. CCA-C is the most commonly used type, known for its balanced composition of chromium, copper, and arsenic, which provides effective protection against a wide range of wood-destroying organisms. This formulation is widely used in residential, commercial, and industrial applications due to its proven efficacy and cost-effectiveness. CCA-C-treated wood is often found in outdoor structures such as decks, fences, and utility poles, where durability and resistance to environmental factors are crucial. On the other hand, CCA-B is a less common formulation, primarily used in specific applications where a lower concentration of arsenic is desired. This type is often chosen for projects with environmental or health considerations, as it offers a reduced risk of leaching harmful chemicals into the surrounding environment. CCA-B-treated wood is typically used in agricultural settings, such as farm structures and fencing, where exposure to soil and moisture is a concern. Lastly, CCA-A is the least commonly used formulation, characterized by its higher concentration of arsenic compared to the other types. This formulation is primarily used in industrial applications where maximum protection against decay and insect infestation is required. CCA-A-treated wood is often found in heavy-duty structures such as marine pilings, railroad ties, and bridge components, where exposure to harsh conditions and heavy loads necessitates superior durability. Despite the effectiveness of CCA wood preservatives, concerns about their environmental impact and potential health risks have led to increased scrutiny and regulation in many regions. As a result, the industry is exploring alternative wood preservation methods and formulations that offer similar levels of protection while minimizing environmental and health risks. This shift towards more sustainable and eco-friendly solutions is expected to shape the future of the CCA wood preservative market, as manufacturers and consumers alike seek to balance performance with environmental responsibility.

Agricultural Wooden Poles, Buildings and Fences, Utility Pole, Highway, Other in the Global CCA wood preservative Market:

The Global CCA wood preservative market plays a crucial role in various applications, including agricultural wooden poles, buildings and fences, utility poles, highways, and other infrastructure projects. In agriculture, CCA-treated wooden poles are widely used for supporting structures such as trellises, fences, and animal enclosures. These poles provide the necessary strength and durability to withstand the elements and resist decay, ensuring long-lasting performance in demanding agricultural environments. In the construction of buildings and fences, CCA-treated wood is favored for its ability to resist rot and insect damage, making it an ideal choice for outdoor applications. This includes residential and commercial structures, where the longevity of the materials is a key consideration. Utility poles, another significant application of CCA-treated wood, benefit from the preservative's ability to protect against decay and insect infestation, ensuring the reliability and safety of electrical and telecommunications infrastructure. In highway construction, CCA-treated wood is used for guardrails, signposts, and other roadside structures, where exposure to weather and environmental conditions necessitates robust protection. Additionally, CCA-treated wood finds use in various other applications, such as marine structures, playground equipment, and landscaping, where its durability and resistance to decay are highly valued. Despite the widespread use of CCA-treated wood, concerns about its environmental impact and potential health risks have led to increased regulation and the development of alternative preservation methods. As the industry continues to evolve, the focus is on finding solutions that offer the same level of protection while minimizing environmental and health concerns. This includes exploring new formulations and treatment methods that reduce the reliance on traditional CCA preservatives, ensuring the continued viability of wood as a sustainable and reliable building material.

Global CCA wood preservative Market Outlook:

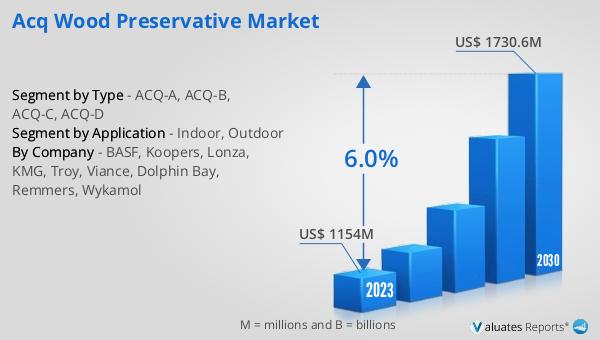

In 2024, the global market for CCA wood preservatives was valued at approximately $1,286 million. This market is anticipated to grow significantly, reaching an estimated value of $1,923 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.0% over the forecast period. The increasing demand for durable and long-lasting wood products, particularly in construction and infrastructure projects, is a key driver of this market expansion. As more regions experience growth in construction activities and infrastructure development, the need for effective wood preservation solutions becomes increasingly important. CCA wood preservatives offer a cost-effective and reliable means of protecting wood from decay and insect damage, making them a popular choice in various applications. However, the market also faces challenges, including environmental concerns and regulatory restrictions on the use of CCA-treated wood in certain regions. These factors have prompted the industry to explore alternative preservation methods and formulations that offer similar levels of protection while minimizing environmental and health risks. Despite these challenges, the global CCA wood preservative market is expected to continue its growth trajectory, driven by the ongoing demand for durable and sustainable wood products. As manufacturers and consumers alike seek to balance performance with environmental responsibility, the industry is poised for continued innovation and development in the coming years.

| Report Metric | Details |

| Report Name | CCA wood preservative Market |

| Accounted market size in year | US$ 1286 million |

| Forecasted market size in 2031 | US$ 1923 million |

| CAGR | 6.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Lonza, Koppers, Viance, Dolphin Bay, Goodfellow, Jinan Delan Chemicals, CRM Yingtan, Foshan Liyuan Chemical, Boda Biochemistry |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |