What is Global SiC Etching Equipment Market?

The Global SiC Etching Equipment Market is a specialized segment within the semiconductor manufacturing industry, focusing on the production and sale of equipment used to etch silicon carbide (SiC) materials. SiC is a compound semiconductor material known for its exceptional thermal, electrical, and mechanical properties, making it ideal for high-power and high-frequency applications. The etching process is a critical step in semiconductor fabrication, where unwanted material is removed to create intricate patterns on the SiC wafers. This market is driven by the increasing demand for SiC-based devices, which are essential in various industries, including automotive, telecommunications, and renewable energy. As the world shifts towards more energy-efficient technologies, the need for advanced SiC etching equipment is expected to grow, supporting the development of next-generation electronic devices. The market encompasses various types of etching equipment, each designed to meet specific requirements of precision, speed, and cost-effectiveness. With continuous advancements in technology, the Global SiC Etching Equipment Market is poised for significant growth, offering opportunities for innovation and expansion in the semiconductor industry.

SiC ICP Etching Equipment, SiC CCP Etching Equipment in the Global SiC Etching Equipment Market:

SiC ICP (Inductively Coupled Plasma) Etching Equipment and SiC CCP (Capacitively Coupled Plasma) Etching Equipment are two primary types of tools used in the Global SiC Etching Equipment Market. SiC ICP Etching Equipment utilizes inductively coupled plasma to achieve high-density plasma generation, which is essential for etching SiC materials with high precision and uniformity. This type of equipment is particularly favored for its ability to provide high etch rates and excellent control over the etching profile, making it suitable for complex and high-aspect-ratio structures. The ICP process involves the use of a radio frequency (RF) power source to generate plasma, which is then used to etch the SiC substrate. The high-density plasma allows for efficient ion bombardment, resulting in precise material removal and smooth surface finishes. On the other hand, SiC CCP Etching Equipment employs capacitively coupled plasma, which is generated by applying an RF power source to parallel plate electrodes. This method is known for its simplicity and cost-effectiveness, making it a popular choice for less demanding applications. CCP etching provides good etch uniformity and selectivity, although it may not achieve the same high etch rates as ICP equipment. Both types of etching equipment play a crucial role in the fabrication of SiC-based devices, each offering distinct advantages depending on the specific requirements of the manufacturing process. As the demand for SiC devices continues to rise, manufacturers are investing in advanced etching technologies to enhance production efficiency and meet the growing needs of various industries. The choice between ICP and CCP etching equipment often depends on factors such as the desired etch profile, throughput, and cost considerations. With ongoing research and development, both ICP and CCP technologies are evolving to offer improved performance and capabilities, further driving the growth of the Global SiC Etching Equipment Market.

SiC Power Devices, GaN-on-SiC RF Devices in the Global SiC Etching Equipment Market:

The Global SiC Etching Equipment Market finds significant applications in the production of SiC Power Devices and GaN-on-SiC RF Devices, both of which are critical components in modern electronic systems. SiC Power Devices, such as diodes and transistors, are widely used in power electronics due to their ability to operate at high voltages, temperatures, and frequencies. These devices are essential for improving the efficiency and performance of power conversion systems, making them ideal for applications in electric vehicles, renewable energy systems, and industrial automation. The etching process is crucial in the fabrication of SiC Power Devices, as it allows for the precise patterning of the SiC substrate, enabling the creation of intricate device structures. Advanced etching equipment ensures high precision and uniformity, which are vital for achieving the desired electrical characteristics and reliability of the devices. Similarly, GaN-on-SiC RF Devices are gaining popularity in the telecommunications industry, particularly for high-frequency applications such as radar systems, satellite communications, and wireless networks. The combination of gallium nitride (GaN) and SiC offers superior thermal conductivity and power handling capabilities, making these devices ideal for high-power RF applications. The etching process is a critical step in the fabrication of GaN-on-SiC RF Devices, as it enables the formation of complex device architectures with high precision and accuracy. The use of advanced SiC etching equipment ensures that the devices meet the stringent performance and reliability requirements of the telecommunications industry. As the demand for high-performance electronic devices continues to grow, the Global SiC Etching Equipment Market is poised to play a vital role in supporting the development and production of next-generation SiC Power Devices and GaN-on-SiC RF Devices. Manufacturers are investing in cutting-edge etching technologies to enhance the efficiency and capabilities of their production processes, ensuring that they can meet the evolving needs of various industries. With the ongoing advancements in semiconductor technology, the Global SiC Etching Equipment Market is expected to witness significant growth, driven by the increasing adoption of SiC-based devices in a wide range of applications.

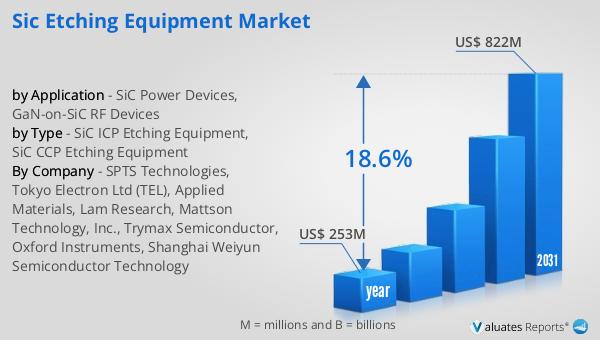

Global SiC Etching Equipment Market Outlook:

In 2024, the global market for SiC Etching Equipment was valued at approximately $253 million. This market is anticipated to experience substantial growth over the coming years, with projections indicating that it will reach an estimated size of $822 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 18.6% during the forecast period. The robust expansion of this market can be attributed to the increasing demand for SiC-based devices across various industries, including automotive, telecommunications, and renewable energy. As these industries continue to seek more efficient and high-performance electronic components, the need for advanced SiC etching equipment is expected to rise. The market's growth is further supported by ongoing technological advancements in etching equipment, which are enhancing the precision, speed, and cost-effectiveness of the etching process. As a result, manufacturers are increasingly investing in state-of-the-art etching technologies to meet the evolving needs of their customers and maintain a competitive edge in the market. With the continued focus on energy efficiency and the development of next-generation electronic devices, the Global SiC Etching Equipment Market is poised for significant growth in the coming years.

| Report Metric | Details |

| Report Name | SiC Etching Equipment Market |

| Accounted market size in year | US$ 253 million |

| Forecasted market size in 2031 | US$ 822 million |

| CAGR | 18.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | SPTS Technologies, Tokyo Electron Ltd (TEL), Applied Materials, Lam Research, Mattson Technology, Inc., Trymax Semiconductor, Oxford Instruments, Shanghai Weiyun Semiconductor Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |