What is Global Six- Dimensional Force Sensors for Robots Market?

The Global Six-Dimensional Force Sensors for Robots Market is a rapidly evolving sector that plays a crucial role in enhancing the capabilities of robotic systems. These sensors are designed to measure forces and torques in six dimensions, providing robots with the ability to interact with their environment in a more sophisticated and precise manner. This technology is essential for applications that require high levels of dexterity and precision, such as assembly, machining, and surgical procedures. By enabling robots to sense and respond to their surroundings, six-dimensional force sensors help improve the efficiency and safety of robotic operations. The market for these sensors is driven by the increasing demand for automation across various industries, including manufacturing, healthcare, and logistics. As industries continue to adopt robotic solutions to improve productivity and reduce operational costs, the demand for advanced sensing technologies like six-dimensional force sensors is expected to grow significantly. This growth is further supported by advancements in sensor technology, which are making these devices more affordable and accessible to a wider range of applications. Overall, the Global Six-Dimensional Force Sensors for Robots Market is poised for substantial growth as it continues to support the development of more intelligent and capable robotic systems.

Strain Gauge Type, Piezoelectric/Capacitive Type, Others in the Global Six- Dimensional Force Sensors for Robots Market:

In the Global Six-Dimensional Force Sensors for Robots Market, different types of sensors are utilized to meet the diverse needs of various applications. Among these, the Strain Gauge Type sensors are widely used due to their high accuracy and reliability. These sensors operate by measuring the deformation or strain of an object when a force is applied, allowing them to detect even the slightest changes in force and torque. This makes them ideal for applications that require precise force measurement, such as in industrial robots used for assembly and machining tasks. On the other hand, Piezoelectric/Capacitive Type sensors offer distinct advantages in terms of sensitivity and dynamic range. These sensors work by converting mechanical stress into an electrical signal, which can then be measured and analyzed. Piezoelectric sensors are particularly useful in applications that involve dynamic or rapidly changing forces, such as in robotic systems used for impact testing or vibration analysis. Capacitive sensors, meanwhile, are known for their ability to measure small displacements and are often used in applications that require high-resolution force measurement. In addition to these two main types, there are other sensor technologies that are also gaining traction in the market. These include optical and magnetic sensors, which offer unique benefits such as non-contact measurement and immunity to electromagnetic interference. Optical sensors, for example, use light to measure force and torque, making them suitable for applications where traditional contact-based sensors may not be feasible. Magnetic sensors, on the other hand, use magnetic fields to detect changes in force and are often used in environments where high levels of electromagnetic interference are present. Each of these sensor types has its own set of advantages and limitations, and the choice of sensor depends on the specific requirements of the application. As the demand for more advanced and capable robotic systems continues to grow, the Global Six-Dimensional Force Sensors for Robots Market is expected to see increased innovation and development in sensor technologies, leading to the introduction of new and improved sensor solutions.

Industrial Robots, Medical Robots, Humanoid Robots, Others in the Global Six- Dimensional Force Sensors for Robots Market:

The usage of Global Six-Dimensional Force Sensors for Robots Market spans across various areas, each benefiting from the enhanced capabilities these sensors provide. In the realm of Industrial Robots, these sensors are crucial for tasks that require high precision and adaptability. They enable robots to perform complex assembly operations, handle delicate materials, and execute tasks with a level of dexterity that was previously unattainable. By providing real-time feedback on force and torque, these sensors allow industrial robots to adjust their actions dynamically, improving efficiency and reducing the risk of damage to products or equipment. In the field of Medical Robots, six-dimensional force sensors play a vital role in enhancing the safety and effectiveness of robotic-assisted surgeries. These sensors provide surgeons with precise control over robotic instruments, allowing for minimally invasive procedures that reduce patient recovery times and improve surgical outcomes. The ability to sense and respond to subtle changes in force and pressure is particularly important in delicate surgical tasks, where precision is paramount. Humanoid Robots, designed to mimic human movements and interactions, also benefit significantly from six-dimensional force sensors. These sensors enable humanoid robots to perform tasks that require human-like dexterity, such as handling objects, interacting with people, and navigating complex environments. By providing feedback on the forces and torques experienced by the robot, these sensors help humanoid robots achieve more natural and intuitive movements, making them more effective in applications such as customer service, caregiving, and entertainment. Beyond these specific areas, six-dimensional force sensors are also used in a variety of other applications, including research and development, where they are used to study the interactions between robots and their environments. As the capabilities of robotic systems continue to expand, the demand for advanced sensing technologies like six-dimensional force sensors is expected to grow, driving further innovation and development in the Global Six-Dimensional Force Sensors for Robots Market.

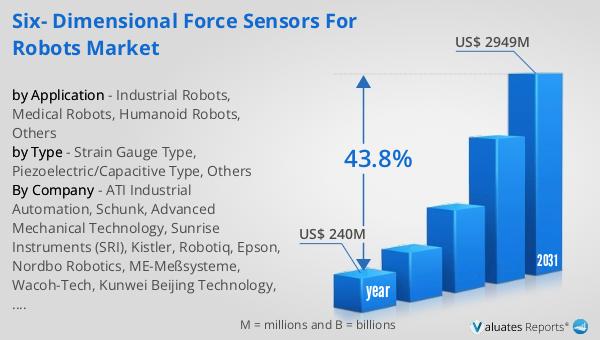

Global Six- Dimensional Force Sensors for Robots Market Outlook:

The global market for Six-Dimensional Force Sensors for Robots was valued at $240 million in 2024 and is anticipated to expand significantly, reaching an estimated size of $2,949 million by 2031, with a robust compound annual growth rate (CAGR) of 43.8% during the forecast period. According to the latest research data from QYR, global sales of six-dimensional force sensors are expected to approach 60,000 units in 2024, with China's sales accounting for approximately 17,000 units, marking a year-on-year increase of over 40%. Projections indicate that by 2030, global market sales will soar to 820,000 units, with China's sales reaching 300,000 units, reflecting a compound annual sales growth rate of 60% from 2025 to 2030. In 2024, the top five manufacturers worldwide are expected to hold more than 60% of the market share. Additionally, the global compound annual growth rate of humanoid robots from 2025 to 2030 is projected to reach an impressive 104%, according to the latest data from QYR. This remarkable growth underscores the increasing demand for advanced robotic technologies and the pivotal role that six-dimensional force sensors play in enhancing the capabilities of robotic systems across various industries.

| Report Metric | Details |

| Report Name | Six- Dimensional Force Sensors for Robots Market |

| Accounted market size in year | US$ 240 million |

| Forecasted market size in 2031 | US$ 2949 million |

| CAGR | 43.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ATI Industrial Automation, Schunk, Advanced Mechanical Technology, Sunrise Instruments (SRI), Kistler, Robotiq, Epson, Nordbo Robotics, ME-Meßsysteme, Wacoh-Tech, Kunwei Beijing Technology, Shenzhen Xinjingcheng Sensing Technolog, Robotous, FUTEK, Blue Point Touch (Beijing) Technology, Bota Systems, FANUC, Changzhou Right Measurement and control system, Hypersen Technologies, Sintokogio, Anhui Zhongke Mi Point Sensor, Nanjing Bio-inspired Intelligent Technology, Aidin Robotics, OnRobot, Guangzhou Haozhi Industrial, Anhui Bioforcen Intelligent Technology, Chongqing Luban Robotics Technology Research Institute, Shenzhen Jia'an Intelligent Technology, Torque Sensor Technology (Shenzhen), Keli Sensing Technolgy(Ningbo), Zhonghang Electronic Measuring Instruments, Shenzhen Ampron Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |