What is Global Nuclear Inspection Camera Market?

The Global Nuclear Inspection Camera Market is a specialized segment within the broader inspection camera industry, focusing on the unique needs of nuclear facilities. These cameras are designed to withstand the harsh environments found in nuclear plants, including high radiation levels, extreme temperatures, and corrosive conditions. They play a crucial role in ensuring the safety and efficiency of nuclear operations by providing visual access to areas that are otherwise inaccessible or too dangerous for human inspection. This market is driven by the increasing demand for nuclear energy, the need for regular maintenance and inspection of aging nuclear facilities, and stringent safety regulations. As nuclear power continues to be a significant part of the global energy mix, the demand for reliable and advanced inspection technologies like nuclear inspection cameras is expected to grow. These cameras not only help in maintaining operational efficiency but also in preventing potential accidents by allowing for early detection of issues. The market encompasses a range of products, from basic analog cameras to sophisticated digital systems, each offering different levels of functionality and durability to meet the specific requirements of nuclear facilities.

Analog Camera, Digital Camera in the Global Nuclear Inspection Camera Market:

In the Global Nuclear Inspection Camera Market, both analog and digital cameras play pivotal roles, each offering distinct advantages and features tailored to the demanding environment of nuclear facilities. Analog cameras, often considered the traditional choice, are valued for their simplicity and reliability. They operate by converting light into an electronic signal, which is then transmitted over coaxial cables to a monitor or recording device. This straightforward technology is particularly advantageous in nuclear settings where durability and resistance to harsh conditions are paramount. Analog cameras are less susceptible to electronic interference, making them ideal for environments with high radiation levels. They also tend to be more cost-effective, which is a significant consideration for facilities operating under tight budget constraints. However, analog cameras have limitations in terms of image resolution and flexibility, which is where digital cameras come into play. Digital cameras, on the other hand, represent the modern evolution of inspection technology. They capture images using digital sensors, which offer higher resolution and greater detail compared to their analog counterparts. This enhanced image quality is crucial for detecting minute defects or anomalies in nuclear facilities, where precision is critical for safety and maintenance. Digital cameras also offer greater flexibility in terms of connectivity and integration with other systems. They can be connected to computer networks, allowing for remote monitoring and data analysis, which is increasingly important in the context of smart facility management. Moreover, digital cameras often come with advanced features such as zoom, pan, and tilt capabilities, as well as the ability to record and store large volumes of data for future reference. Despite their advantages, digital cameras also face challenges in the nuclear inspection market. They are generally more expensive than analog cameras, both in terms of initial purchase and maintenance costs. Additionally, digital cameras can be more susceptible to electronic interference, which can be a concern in high-radiation environments. To mitigate these issues, manufacturers are continuously working on developing more robust digital cameras that can withstand the unique challenges of nuclear facilities. This includes the use of radiation-hardened components and advanced shielding techniques to protect sensitive electronic parts. In summary, both analog and digital cameras have their place in the Global Nuclear Inspection Camera Market. The choice between the two often depends on the specific needs and constraints of the nuclear facility in question. While analog cameras offer reliability and cost-effectiveness, digital cameras provide superior image quality and advanced features. As technology continues to evolve, the line between analog and digital is likely to blur, with hybrid solutions emerging to offer the best of both worlds. Ultimately, the goal is to ensure the safety and efficiency of nuclear operations through reliable and effective inspection technologies.

Nuclear Industry Facility Operation and Maintenance, Nuclear Waste Treatment in the Global Nuclear Inspection Camera Market:

The Global Nuclear Inspection Camera Market finds significant application in various areas of the nuclear industry, particularly in facility operation and maintenance, as well as nuclear waste treatment. In the realm of nuclear facility operation and maintenance, inspection cameras are indispensable tools. They allow operators to visually inspect critical components and systems without the need for direct human intervention, which is crucial in environments where radiation levels can pose significant health risks. These cameras are used to monitor the condition of reactors, turbines, and other essential equipment, helping to identify wear and tear or potential failures before they lead to costly downtime or accidents. By providing real-time visual data, inspection cameras enable maintenance teams to make informed decisions about repairs and replacements, thereby enhancing the overall safety and efficiency of nuclear operations. In addition to routine maintenance, nuclear inspection cameras are also vital during shutdowns and outages. During these periods, thorough inspections are conducted to ensure that all systems are functioning correctly and that any necessary repairs are made. Inspection cameras allow for detailed examinations of areas that are difficult to access, such as the interior of reactor vessels or the underside of large machinery. This capability is particularly important in the context of aging nuclear facilities, where the risk of component degradation is higher. By facilitating comprehensive inspections, these cameras help to extend the operational lifespan of nuclear plants and reduce the likelihood of unexpected failures. Beyond facility operation and maintenance, the Global Nuclear Inspection Camera Market also plays a crucial role in nuclear waste treatment. The handling and disposal of nuclear waste are among the most challenging aspects of the nuclear industry, requiring stringent safety measures and precise operations. Inspection cameras are used to monitor the condition of waste storage containers, ensuring that they remain intact and free from leaks. They also assist in the inspection of waste processing equipment, helping to detect any issues that could compromise the safety of waste handling procedures. By providing clear and detailed visual data, these cameras enable operators to maintain high standards of safety and compliance with regulatory requirements. Moreover, inspection cameras are instrumental in the decommissioning of nuclear facilities. As plants reach the end of their operational life, they must be safely dismantled and decontaminated. This process involves the careful removal and disposal of radioactive materials, a task that requires precise planning and execution. Inspection cameras provide the necessary visual access to monitor decommissioning activities, ensuring that all procedures are carried out safely and efficiently. They help to identify any residual contamination and verify that decontamination efforts are successful, thereby minimizing the environmental impact of decommissioning operations. In conclusion, the Global Nuclear Inspection Camera Market is integral to the safe and efficient operation of nuclear facilities. Whether in the context of routine maintenance, waste treatment, or decommissioning, these cameras provide the critical visual data needed to ensure that all activities are conducted safely and in compliance with regulatory standards. As the nuclear industry continues to evolve, the demand for advanced inspection technologies is likely to grow, underscoring the importance of ongoing innovation in this field.

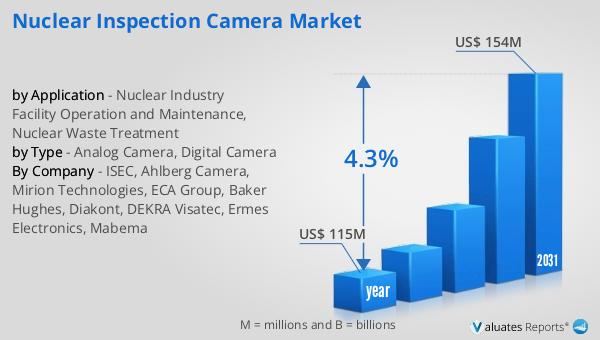

Global Nuclear Inspection Camera Market Outlook:

The outlook for the Global Nuclear Inspection Camera Market indicates a promising trajectory. In 2024, the market was valued at approximately US$ 115 million, reflecting its established importance in the nuclear industry. Looking ahead, projections suggest that by 2031, the market will expand to a revised size of around US$ 154 million. This growth is expected to occur at a compound annual growth rate (CAGR) of 4.3% over the forecast period. This steady increase underscores the growing recognition of the critical role that inspection cameras play in ensuring the safety and efficiency of nuclear operations. As nuclear facilities continue to age and the demand for nuclear energy remains strong, the need for reliable and advanced inspection technologies is more pressing than ever. The market's expansion is likely driven by several factors, including technological advancements in camera design, increasing regulatory requirements for safety and maintenance, and the ongoing need for efficient waste management solutions. As the industry continues to innovate, the capabilities of nuclear inspection cameras are expected to evolve, offering even greater precision and reliability. This positive market outlook highlights the essential nature of these technologies in supporting the safe and sustainable operation of nuclear facilities worldwide.

| Report Metric | Details |

| Report Name | Nuclear Inspection Camera Market |

| Accounted market size in year | US$ 115 million |

| Forecasted market size in 2031 | US$ 154 million |

| CAGR | 4.3% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | ISEC, Ahlberg Camera, Mirion Technologies, ECA Group, Baker Hughes, Diakont, DEKRA Visatec, Ermes Electronics, Mabema |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |