What is Global SPS (Suspension Plasma Spray) Market?

The Global SPS (Suspension Plasma Spray) Market is a specialized segment within the broader thermal spray coating industry. This market focuses on the use of suspension plasma spray technology, which involves the spraying of a suspension containing fine particles onto a substrate to create a coating. This method is particularly advantageous for producing coatings with unique properties, such as enhanced wear resistance, thermal insulation, and corrosion protection. The SPS process is highly versatile and can be used with a wide range of materials, including ceramics, metals, and composites. It is widely employed in industries such as aerospace, automotive, energy, and electronics, where high-performance coatings are essential. The market is driven by the increasing demand for advanced coating solutions that can withstand extreme conditions and extend the lifespan of components. As industries continue to seek innovative ways to improve efficiency and durability, the Global SPS Market is expected to grow, offering new opportunities for manufacturers and service providers. The technology's ability to produce coatings with precise microstructures and tailored properties makes it a valuable tool in the development of next-generation materials and products.

Y₂O₃ Coating, Others in the Global SPS (Suspension Plasma Spray) Market:

Y₂O₃ Coating, also known as yttrium oxide coating, is a significant component of the Global SPS (Suspension Plasma Spray) Market. Yttrium oxide is a ceramic material known for its excellent thermal and chemical stability, making it an ideal choice for protective coatings in harsh environments. In the SPS process, yttrium oxide is suspended in a liquid medium and sprayed onto a substrate using a plasma torch. This results in a dense, uniform coating that can withstand high temperatures and corrosive conditions. Y₂O₃ coatings are particularly valuable in the semiconductor industry, where they are used to protect equipment parts from plasma etching and chemical attacks. The coatings help to extend the lifespan of components, reduce maintenance costs, and improve overall process efficiency. In addition to the semiconductor industry, Y₂O₃ coatings are also used in the aerospace and energy sectors, where they provide thermal barrier protection for turbine blades and other high-temperature components. The demand for Y₂O₃ coatings is driven by the need for advanced materials that can enhance the performance and reliability of critical systems. As industries continue to push the boundaries of technology, the role of Y₂O₃ coatings in the SPS market is expected to grow, offering new opportunities for innovation and development. The versatility of yttrium oxide, combined with the precision of the SPS process, allows for the creation of coatings with tailored properties, meeting the specific needs of various applications. This adaptability is a key factor in the increasing adoption of Y₂O₃ coatings across different industries. Furthermore, the environmental benefits of using yttrium oxide, such as its non-toxic nature and recyclability, make it an attractive option for companies looking to reduce their environmental footprint. As the demand for sustainable solutions continues to rise, the use of Y₂O₃ coatings in the SPS market is likely to expand, contributing to the development of greener technologies. The ongoing research and development efforts in the field of suspension plasma spray technology are expected to lead to further advancements in Y₂O₃ coatings, enhancing their performance and broadening their range of applications. This continuous innovation is essential for meeting the evolving needs of industries and maintaining the competitiveness of the Global SPS Market.

Etch (like Inner Liner, GDP), Others Semiconductor Equipment Parts in the Global SPS (Suspension Plasma Spray) Market:

The Global SPS (Suspension Plasma Spray) Market plays a crucial role in the semiconductor industry, particularly in the production of etch components such as inner liners and gas distribution plates (GDP). These components are essential for the etching process, which involves the removal of material from a substrate to create intricate patterns and structures. The SPS process is used to apply protective coatings to these components, enhancing their durability and resistance to the harsh conditions of the etching environment. Inner liners, for example, are coated with materials that can withstand high temperatures and corrosive gases, ensuring the integrity of the etching chamber and preventing contamination of the substrate. Similarly, GDPs are coated to improve their resistance to wear and chemical attack, extending their lifespan and reducing the need for frequent replacements. The use of SPS technology in the semiconductor industry is driven by the need for high-performance coatings that can meet the stringent requirements of modern manufacturing processes. As the demand for smaller, more complex semiconductor devices continues to grow, the importance of reliable and efficient etching components becomes increasingly critical. In addition to etch components, the Global SPS Market also serves other semiconductor equipment parts, providing coatings that enhance their performance and longevity. For instance, SPS coatings are used on wafer handling equipment to reduce friction and prevent particle generation, ensuring the smooth and efficient movement of wafers throughout the manufacturing process. The ability of SPS technology to produce coatings with precise microstructures and tailored properties makes it an invaluable tool for the semiconductor industry, where even the smallest imperfections can have significant consequences. The ongoing advancements in suspension plasma spray technology are expected to lead to further improvements in the performance and reliability of semiconductor equipment parts, supporting the continued growth and innovation of the industry. As the semiconductor market evolves, the role of the Global SPS Market in providing advanced coating solutions will remain essential, driving the development of new materials and processes that can meet the challenges of tomorrow's technologies.

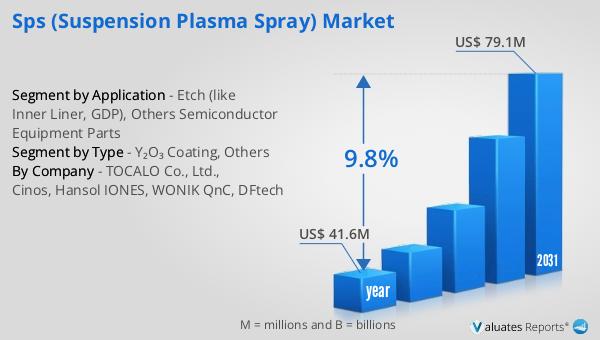

Global SPS (Suspension Plasma Spray) Market Outlook:

The global market for SPS Suspension Plasma Spray was valued at approximately $41.6 million in 2024, and it is anticipated to grow significantly over the coming years. By 2031, the market is projected to reach an estimated size of $79.1 million, reflecting a compound annual growth rate (CAGR) of 9.8% during the forecast period. This growth is indicative of the increasing demand for advanced coating technologies across various industries. The SPS process offers unique advantages, such as the ability to produce coatings with tailored properties and precise microstructures, making it an attractive option for applications requiring high-performance materials. Industries such as aerospace, automotive, energy, and electronics are driving the demand for SPS technology, as they seek to enhance the durability, efficiency, and reliability of their products. The market's expansion is also supported by ongoing research and development efforts aimed at improving the performance and versatility of SPS coatings. As industries continue to innovate and push the boundaries of technology, the Global SPS Market is poised to play a critical role in the development of next-generation materials and products. The projected growth of the market underscores the importance of SPS technology in meeting the evolving needs of industries and supporting the advancement of cutting-edge technologies.

| Report Metric | Details |

| Report Name | SPS (Suspension Plasma Spray) Market |

| Accounted market size in year | US$ 41.6 million |

| Forecasted market size in 2031 | US$ 79.1 million |

| CAGR | 9.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | TOCALO Co., Ltd., Cinos, Hansol IONES, WONIK QnC, DFtech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |