What is Global Thermally Conductive Spherical Alumina Powder Market?

The Global Thermally Conductive Spherical Alumina Powder Market is a specialized segment within the broader materials industry, focusing on the production and distribution of alumina powder with enhanced thermal conductivity properties. This type of alumina powder is engineered into spherical shapes to improve its flowability and packing density, which are critical for its application in various high-performance materials. The primary function of thermally conductive spherical alumina powder is to facilitate efficient heat dissipation in electronic components and systems, thereby enhancing their performance and longevity. This market is driven by the increasing demand for advanced thermal management solutions in industries such as electronics, automotive, and telecommunications. As electronic devices become more compact and powerful, the need for effective thermal management materials like spherical alumina powder becomes more pronounced. The market is characterized by continuous innovation and development, with manufacturers striving to improve the thermal conductivity and mechanical properties of their products. Additionally, environmental regulations and the push for sustainable materials are influencing market dynamics, encouraging the development of eco-friendly production processes and products. Overall, the Global Thermally Conductive Spherical Alumina Powder Market plays a crucial role in supporting the advancement of technology by providing essential materials for thermal management applications.

50μm Below, 50-100μm, 100μm Above in the Global Thermally Conductive Spherical Alumina Powder Market:

In the Global Thermally Conductive Spherical Alumina Powder Market, the particle size of the alumina powder is a critical factor that influences its application and performance. The market is segmented based on particle size into three main categories: 50μm Below, 50-100μm, and 100μm Above. Each of these categories serves different purposes and is selected based on the specific requirements of the application. The 50μm Below category is typically used in applications where a high degree of precision and uniformity is required. These smaller particles offer a larger surface area, which can enhance the thermal conductivity of the material they are incorporated into. They are often used in applications such as thermal interface materials, where efficient heat transfer is crucial. The 50-100μm category represents a balance between surface area and packing density. These particles are versatile and can be used in a wide range of applications, including thermal conductive engineering plastics and aluminum-based copper-clad laminates. Their size allows for good flowability and ease of processing, making them a popular choice for manufacturers looking to optimize both performance and production efficiency. The 100μm Above category is used in applications where high packing density and mechanical strength are prioritized. These larger particles are often used in structural applications where the material needs to withstand mechanical stress while still providing effective thermal management. The choice of particle size is influenced by factors such as the desired thermal conductivity, mechanical properties, and processing requirements of the final product. Manufacturers in the Global Thermally Conductive Spherical Alumina Powder Market must carefully consider these factors when selecting the appropriate particle size for their applications. Additionally, advancements in production technology are enabling the development of alumina powders with more precise particle size distributions, further enhancing their performance and expanding their range of applications. As industries continue to demand more efficient and reliable thermal management solutions, the importance of selecting the right particle size in the Global Thermally Conductive Spherical Alumina Powder Market cannot be overstated. This segmentation allows manufacturers to tailor their products to meet the specific needs of their customers, ensuring optimal performance and satisfaction.

Thermal Interface Materials, Thermal Conductive Engineering Plastics, Thermal Conductive Aluminum-Based Copper-Clad Laminates, Others in the Global Thermally Conductive Spherical Alumina Powder Market:

The Global Thermally Conductive Spherical Alumina Powder Market finds its applications in several key areas, each with unique requirements and benefits. One of the primary applications is in Thermal Interface Materials (TIMs). These materials are crucial in electronic devices, where they serve as a bridge between heat-generating components and heat sinks. The spherical shape and high thermal conductivity of alumina powder enhance the efficiency of TIMs, ensuring effective heat dissipation and preventing overheating. This is particularly important in high-performance computing and telecommunications equipment, where maintaining optimal operating temperatures is critical for performance and reliability. Another significant application is in Thermal Conductive Engineering Plastics. These plastics are used in various industries, including automotive and consumer electronics, where they provide both structural support and thermal management. The incorporation of spherical alumina powder into these plastics improves their thermal conductivity without compromising their mechanical properties. This allows manufacturers to produce lightweight, durable components that can withstand high temperatures, making them ideal for use in electric vehicles and other advanced technologies. Thermal Conductive Aluminum-Based Copper-Clad Laminates are another area where spherical alumina powder is extensively used. These laminates are used in printed circuit boards (PCBs) and other electronic components, where they provide a combination of electrical insulation and thermal management. The addition of alumina powder enhances the thermal conductivity of the laminates, allowing for more efficient heat dissipation and improved performance of the electronic components. This is particularly important in high-density electronic applications, where space is limited, and efficient thermal management is essential. Beyond these specific applications, spherical alumina powder is also used in a variety of other areas, including adhesives, sealants, and coatings. In these applications, the powder provides enhanced thermal conductivity and improved mechanical properties, making it a versatile and valuable material for manufacturers. The ability to tailor the properties of spherical alumina powder to meet the specific needs of different applications is a key factor driving its adoption across various industries. As the demand for advanced thermal management solutions continues to grow, the Global Thermally Conductive Spherical Alumina Powder Market is expected to play an increasingly important role in supporting the development of new technologies and products.

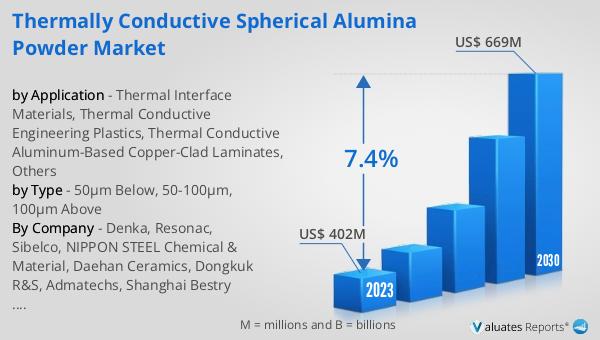

Global Thermally Conductive Spherical Alumina Powder Market Outlook:

The outlook for the Global Thermally Conductive Spherical Alumina Powder Market is promising, with significant growth anticipated over the coming years. In 2023, the market was valued at approximately US$ 402 million, reflecting its importance in various high-tech industries. Looking ahead, the market is expected to expand substantially, reaching an estimated value of US$ 669 million by 2030. This growth trajectory represents a compound annual growth rate (CAGR) of 7.4% during the forecast period from 2024 to 2030. This robust growth is driven by several factors, including the increasing demand for efficient thermal management solutions in electronics, automotive, and telecommunications sectors. As electronic devices become more compact and powerful, the need for materials that can effectively dissipate heat becomes more critical. Spherical alumina powder, with its superior thermal conductivity and mechanical properties, is well-positioned to meet this demand. Additionally, advancements in production technology and the development of eco-friendly materials are expected to further boost the market's growth. Manufacturers are continually innovating to improve the performance and sustainability of their products, ensuring that they meet the evolving needs of their customers. Overall, the Global Thermally Conductive Spherical Alumina Powder Market is poised for significant growth, driven by the increasing demand for advanced thermal management solutions and the continuous development of new and improved products.

| Report Metric | Details |

| Report Name | Thermally Conductive Spherical Alumina Powder Market |

| Accounted market size in 2023 | US$ 402 million |

| Forecasted market size in 2030 | US$ 669 million |

| CAGR | 7.4% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Denka, Resonac, Sibelco, NIPPON STEEL Chemical & Material, Daehan Ceramics, Dongkuk R&S, Admatechs, Shanghai Bestry Performance Materials, Anhui Estone Materials Technology, Lianyungang Donghai Silicon Powder, Bengbu Zhongheng New Material Technology (China Building Materials Group), Dongguan Dongchao New Materials Technology, Luoyang Zhongchao Aluminum Industry, Henan Tianma New Material, Zibo Zhengzheng Aluminum Industry, China Mineral Processing (CMP), Jiangsu Shengtian New Materials, Lanling County Yixin Mining Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |