What is Global Roller LM Guide Market?

The Global Roller LM Guide Market is a specialized segment within the broader linear motion technology industry. Linear Motion (LM) Guides are essential components used in various machinery to facilitate smooth and precise linear movements. The "roller" aspect refers to the use of cylindrical rollers within the guide, which offer higher load capacities and rigidity compared to ball-based LM guides. This market is driven by the increasing demand for automation and precision in industries such as manufacturing, automotive, and electronics. As industries strive for higher efficiency and accuracy, the need for robust and reliable linear motion solutions like roller LM guides becomes critical. These guides are integral in applications where high load capacity, rigidity, and precision are paramount. The market is characterized by continuous innovation, with manufacturers focusing on enhancing the performance and durability of these guides to meet the evolving needs of various sectors. The global reach of this market is evident as it caters to diverse industries across different regions, each with unique requirements and challenges. As technology advances, the Global Roller LM Guide Market is poised to play a crucial role in supporting the next generation of industrial machinery and automation solutions.

Caged Roller LM Guide, Full-Roller LM Guide in the Global Roller LM Guide Market:

The Caged Roller LM Guide and Full-Roller LM Guide are two prominent types of roller linear motion guides that cater to different industrial needs within the Global Roller LM Guide Market. The Caged Roller LM Guide is designed with a cage that holds the rollers in place, ensuring smooth and quiet operation. This design minimizes friction and wear, leading to longer service life and reduced maintenance costs. The cage also prevents the rollers from colliding with each other, which enhances the guide's performance in high-speed applications. This type of guide is particularly beneficial in environments where noise reduction and maintenance efficiency are critical. On the other hand, the Full-Roller LM Guide is engineered for applications requiring maximum load capacity and rigidity. Unlike the caged version, the full-roller design allows for a greater number of rollers to be in contact with the rail, distributing the load more evenly and providing superior stability. This makes it ideal for heavy-duty applications where precision and durability are essential. The full-roller design is often used in industries such as automotive manufacturing and heavy machinery, where the ability to handle substantial loads without compromising on accuracy is crucial. Both types of guides are integral to the Global Roller LM Guide Market, each offering unique advantages that cater to specific industrial requirements. Manufacturers in this market are continually innovating to enhance the performance and reliability of these guides, ensuring they meet the diverse needs of their customers. As industries evolve and demand more sophisticated motion solutions, the Caged Roller LM Guide and Full-Roller LM Guide will continue to play a vital role in supporting the advancement of technology and automation.

Machine Tools and Injection Molding Machines, Semiconductor and LCD Production Equipment, Factory Automation, Automotive, Others in the Global Roller LM Guide Market:

The Global Roller LM Guide Market finds extensive usage across various industries, each leveraging the unique benefits of these guides to enhance their operations. In the realm of Machine Tools and Injection Molding Machines, roller LM guides are indispensable due to their ability to provide precise and stable linear motion. These machines require high accuracy and repeatability, which roller LM guides deliver by minimizing friction and ensuring smooth movement. This precision is crucial for producing high-quality components and maintaining the efficiency of the manufacturing process. In the Semiconductor and LCD Production Equipment sector, the demand for roller LM guides is driven by the need for ultra-precision and cleanroom compatibility. These guides are designed to operate in environments where even the slightest contamination can lead to defects in the final product. The high load capacity and rigidity of roller LM guides make them ideal for supporting the delicate and precise operations required in semiconductor and LCD manufacturing. Factory Automation is another area where roller LM guides play a pivotal role. As industries move towards greater automation, the need for reliable and efficient linear motion solutions becomes paramount. Roller LM guides provide the necessary support for automated systems, ensuring smooth and accurate movement of components and machinery. This enhances the overall efficiency and productivity of automated processes. In the Automotive industry, roller LM guides are used in various applications, from assembly lines to testing equipment. Their ability to handle high loads and provide precise motion makes them ideal for the rigorous demands of automotive manufacturing. Finally, roller LM guides are also utilized in other sectors such as aerospace, medical equipment, and robotics, where precision and reliability are critical. The versatility and performance of roller LM guides make them a valuable asset in any industry that requires precise linear motion solutions.

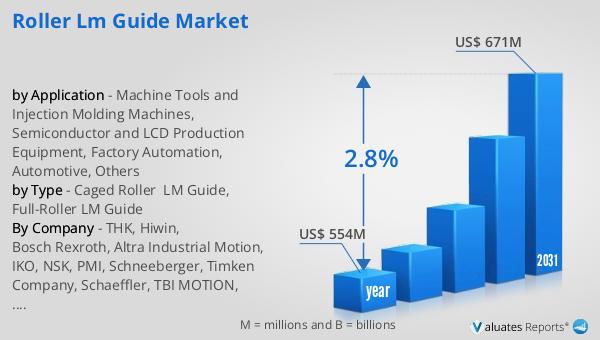

Global Roller LM Guide Market Outlook:

The global market for Roller LM Guide was valued at approximately $554 million in 2024, and projections indicate that it will grow to a revised size of around $671 million by 2031. This growth represents a compound annual growth rate (CAGR) of 2.8% over the forecast period. This steady growth reflects the increasing demand for precision and efficiency in various industries that rely on linear motion technology. The market's expansion is driven by the continuous advancements in automation and manufacturing processes, which require robust and reliable motion solutions. As industries evolve and adopt more sophisticated technologies, the need for high-performance roller LM guides becomes more pronounced. The market's growth is also supported by the rising demand for high-load capacity and precision in applications such as automotive manufacturing, semiconductor production, and factory automation. The projected growth of the Global Roller LM Guide Market underscores the critical role these components play in modern industrial applications. As manufacturers continue to innovate and enhance the performance of roller LM guides, the market is expected to maintain its upward trajectory, catering to the diverse needs of industries worldwide.

| Report Metric | Details |

| Report Name | Roller LM Guide Market |

| Accounted market size in year | US$ 554 million |

| Forecasted market size in 2031 | US$ 671 million |

| CAGR | 2.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | THK, Hiwin, Bosch Rexroth, Altra Industrial Motion, IKO, NSK, PMI, Schneeberger, Timken Company, Schaeffler, TBI MOTION, Hanjiang Machine Tool, Shandong Best Precision |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |