What is Global SPS (Suspension Plasma Spray) Coating Market?

The Global SPS (Suspension Plasma Spray) Coating Market is a specialized segment within the broader coatings industry, focusing on the application of advanced thermal spray technology. This market involves the use of suspension plasma spray, a process that utilizes a liquid suspension of fine particles to create coatings with unique properties. These coatings are applied to various substrates to enhance their surface characteristics, such as wear resistance, thermal insulation, and corrosion protection. The SPS technique is particularly valued for its ability to produce coatings with a high degree of uniformity and density, making it suitable for applications in demanding environments. Industries such as aerospace, automotive, and electronics are key consumers of SPS coatings, leveraging their benefits to improve the performance and longevity of components. The market is driven by the increasing demand for high-performance materials and the continuous advancements in coating technologies. As industries seek to enhance the durability and efficiency of their products, the adoption of SPS coatings is expected to grow, supported by ongoing research and development efforts aimed at optimizing the process and expanding its applications.

Y₂O₃ Coating, Others in the Global SPS (Suspension Plasma Spray) Coating Market:

Y₂O₃ Coating, or yttrium oxide coating, is a significant component of the Global SPS (Suspension Plasma Spray) Coating Market. Yttrium oxide is a rare earth compound known for its excellent thermal and chemical stability, making it an ideal material for protective coatings in high-temperature and corrosive environments. In the context of SPS, Y₂O₃ coatings are applied using a suspension of fine yttrium oxide particles, which are deposited onto substrates through a plasma spray process. This method allows for the creation of dense, uniform coatings that adhere strongly to the underlying material. The primary advantage of Y₂O₃ coatings is their ability to withstand extreme conditions, such as those found in semiconductor manufacturing and aerospace applications. In semiconductor equipment, for instance, Y₂O₃ coatings are used to protect components from the harsh chemical environments encountered during processes like etching and deposition. The coatings help to extend the lifespan of these components, reduce maintenance costs, and improve overall process efficiency. Additionally, Y₂O₃ coatings are employed in the aerospace industry to protect engine components from high temperatures and oxidative environments, thereby enhancing their performance and reliability. The demand for Y₂O₃ coatings is driven by the need for materials that can endure increasingly challenging operational conditions, as well as the ongoing development of new technologies that require advanced protective solutions. As industries continue to push the boundaries of performance and efficiency, the role of Y₂O₃ coatings in the SPS market is expected to expand, supported by innovations in coating techniques and materials science. Other coatings within the SPS market include a variety of materials tailored to specific applications, each offering unique properties that address the diverse needs of different industries. For example, ceramic coatings are widely used for their thermal barrier properties, providing insulation and protection in high-temperature environments. These coatings are essential in industries such as power generation and automotive, where they help to improve the efficiency and durability of engines and turbines. Metal coatings, on the other hand, are valued for their electrical conductivity and corrosion resistance, making them suitable for applications in electronics and marine environments. The versatility of the SPS process allows for the customization of coatings to meet specific performance criteria, enabling manufacturers to optimize their products for a wide range of applications. As the demand for high-performance materials continues to grow, the SPS coating market is poised to play a crucial role in the development of innovative solutions that address the evolving challenges of modern industry.

Etch (like Inner Liner, GDP), Others Semiconductor Equipment Parts in the Global SPS (Suspension Plasma Spray) Coating Market:

The Global SPS (Suspension Plasma Spray) Coating Market finds extensive usage in various sectors, particularly in the semiconductor industry, where it plays a crucial role in enhancing the performance and durability of equipment parts. One of the primary applications of SPS coatings in this field is in the etch process, which involves the removal of material from a substrate to create intricate patterns and structures. During etching, components are exposed to aggressive chemical environments that can lead to wear and degradation over time. SPS coatings, such as Y₂O₃, are applied to protect these components, ensuring their longevity and reducing the need for frequent replacements. The inner liner of etch chambers, for instance, benefits significantly from SPS coatings, as they provide a robust barrier against corrosive gases and plasma, thereby maintaining the integrity of the chamber and improving process consistency. Similarly, gas distribution plates (GDP) in semiconductor equipment are coated with SPS materials to enhance their resistance to chemical attack and thermal stress. These coatings help to maintain the precise flow of gases required for semiconductor fabrication, contributing to higher yields and improved device performance. Beyond the semiconductor industry, SPS coatings are also utilized in other areas where equipment parts are subjected to harsh conditions. In the aerospace sector, for example, SPS coatings are applied to turbine blades and other engine components to protect them from high temperatures and oxidative environments. This not only extends the lifespan of these components but also enhances the overall efficiency and reliability of the engines. In the automotive industry, SPS coatings are used to improve the thermal management of engine parts, reducing heat loss and increasing fuel efficiency. The versatility of SPS coatings allows them to be tailored to meet the specific requirements of different applications, making them an invaluable tool for manufacturers seeking to optimize the performance and durability of their products. As industries continue to evolve and face new challenges, the demand for advanced coating solutions like those offered by the SPS market is expected to grow. The ongoing development of new materials and coating techniques will further expand the range of applications for SPS coatings, enabling them to address the increasingly complex needs of modern industry.

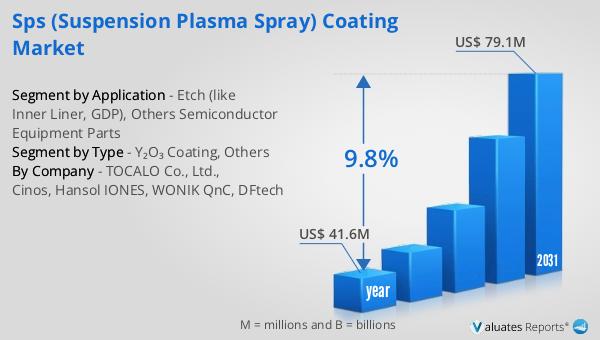

Global SPS (Suspension Plasma Spray) Coating Market Outlook:

The global market for SPS Suspension Plasma Spray Coating was valued at $41.6 million in 2024, and it is anticipated to grow significantly, reaching an estimated $79.1 million by 2031. This growth represents a compound annual growth rate (CAGR) of 9.8% over the forecast period. This upward trajectory underscores the increasing demand for advanced coating technologies across various industries. The SPS coating market is driven by the need for high-performance materials that can withstand extreme conditions and enhance the durability and efficiency of components. As industries such as aerospace, automotive, and electronics continue to push the boundaries of performance, the adoption of SPS coatings is expected to rise. The market's growth is also supported by ongoing research and development efforts aimed at optimizing the SPS process and expanding its applications. Innovations in coating materials and techniques are enabling manufacturers to create customized solutions that meet the specific needs of different industries. As a result, the SPS coating market is poised to play a crucial role in the development of innovative solutions that address the evolving challenges of modern industry. The projected growth of the SPS market reflects the increasing importance of advanced coating technologies in enhancing the performance and longevity of components across a wide range of applications.

| Report Metric | Details |

| Report Name | SPS (Suspension Plasma Spray) Coating Market |

| Accounted market size in year | US$ 41.6 million |

| Forecasted market size in 2031 | US$ 79.1 million |

| CAGR | 9.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | TOCALO Co., Ltd., Cinos, Hansol IONES, WONIK QnC, DFtech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |