What is Global Surface Treatment for Advanced Ceramic Parts Market?

Global Surface Treatment for Advanced Ceramic Parts Market refers to the specialized processes applied to enhance the properties and performance of advanced ceramic components. These treatments are crucial in improving the durability, functionality, and aesthetic appeal of ceramic parts used in various industries. Advanced ceramics are known for their exceptional hardness, thermal stability, and resistance to wear and corrosion, making them ideal for high-performance applications. However, to further optimize their performance, surface treatments are employed. These treatments can include processes like precision cleaning, coating, anodizing, and other specialized techniques. The goal is to modify the surface characteristics of ceramic parts to meet specific requirements, such as increased resistance to environmental factors, improved electrical conductivity, or enhanced bonding capabilities. The global market for these treatments is driven by the growing demand for advanced ceramics in industries such as electronics, automotive, aerospace, and healthcare. As technology advances and industries seek more efficient and reliable materials, the importance of surface treatments for advanced ceramic parts continues to grow, making it a vital component of the global materials market.

Precision Cleaning, Coating, Anodizing, Others in the Global Surface Treatment for Advanced Ceramic Parts Market:

Precision cleaning, coating, anodizing, and other surface treatment techniques play a pivotal role in the Global Surface Treatment for Advanced Ceramic Parts Market. Precision cleaning is a critical process that ensures the removal of contaminants from ceramic surfaces, which is essential for maintaining the integrity and performance of the parts. This process involves the use of specialized cleaning agents and techniques to eliminate particles, residues, and films that could compromise the functionality of the ceramic components. By achieving a high level of cleanliness, precision cleaning enhances the reliability and longevity of ceramic parts, particularly in sensitive applications like semiconductors and medical devices. Coating, on the other hand, involves applying a layer of material onto the ceramic surface to impart specific properties. This can include protective coatings that enhance resistance to wear, corrosion, or high temperatures. Coatings can also be functional, such as conductive coatings for electronic applications or biocompatible coatings for medical implants. The choice of coating material and method depends on the intended application and desired properties. Anodizing, although more commonly associated with metals, can also be applied to certain ceramic materials to improve their surface characteristics. This electrochemical process creates a durable oxide layer on the surface, enhancing properties like corrosion resistance and surface hardness. Anodizing can also be used to impart aesthetic qualities, such as color, to ceramic parts. Other surface treatment techniques may include laser texturing, ion implantation, or chemical vapor deposition, each offering unique benefits depending on the application. These treatments are tailored to meet the specific needs of industries utilizing advanced ceramics, ensuring that the parts perform optimally under various conditions. The demand for these surface treatments is driven by the increasing use of advanced ceramics in high-tech industries, where performance and reliability are paramount. As industries continue to push the boundaries of technology, the role of surface treatments in enhancing the capabilities of advanced ceramic parts becomes increasingly significant.

Semiconductor, Display Panel in the Global Surface Treatment for Advanced Ceramic Parts Market:

The usage of Global Surface Treatment for Advanced Ceramic Parts Market is particularly prominent in the semiconductor and display panel industries. In the semiconductor industry, advanced ceramics are used in various components due to their excellent thermal and electrical properties. Surface treatments are essential in this context to ensure that ceramic parts meet the stringent requirements of semiconductor manufacturing. Precision cleaning is crucial to remove any contaminants that could interfere with the delicate processes involved in semiconductor fabrication. Coatings are often applied to enhance the thermal management capabilities of ceramic components, ensuring efficient heat dissipation and maintaining the stability of semiconductor devices. Anodizing and other surface treatments can also be employed to improve the durability and performance of ceramic parts used in semiconductor equipment. In the display panel industry, advanced ceramics are used in components such as substrates and insulating layers. Surface treatments are vital to enhance the optical properties of these ceramics, ensuring clarity and color accuracy in display panels. Coatings can be applied to improve the scratch resistance and longevity of ceramic components, which is crucial for maintaining the quality and performance of display panels over time. The precision and reliability offered by surface-treated ceramic parts are essential in meeting the high standards of the display panel industry, where even minor imperfections can significantly impact product performance. As the demand for high-resolution displays and advanced semiconductor devices continues to grow, the importance of surface treatments for advanced ceramic parts in these industries becomes increasingly evident. These treatments not only enhance the performance and reliability of ceramic components but also contribute to the overall efficiency and effectiveness of semiconductor and display panel manufacturing processes.

Global Surface Treatment for Advanced Ceramic Parts Market Outlook:

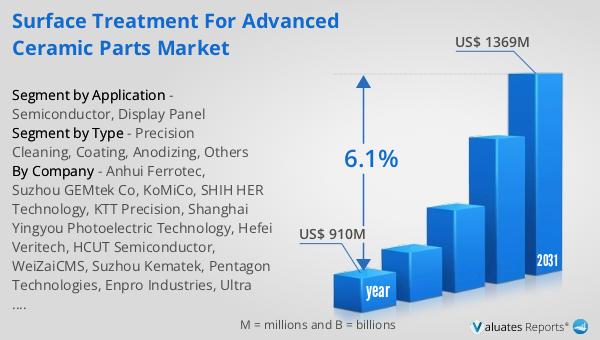

The global market for Surface Treatment for Advanced Ceramic Parts was valued at approximately 910 million USD in 2024. It is anticipated to expand to a revised size of around 1369 million USD by the year 2031, reflecting a compound annual growth rate (CAGR) of 6.1% during the forecast period. This growth trajectory underscores the increasing demand for advanced ceramic parts across various industries and the critical role that surface treatments play in enhancing their performance. The market's expansion is driven by the need for high-performance materials that can withstand extreme conditions and deliver reliable results in applications ranging from electronics to aerospace. As industries continue to innovate and seek materials that offer superior properties, the demand for surface treatments that can optimize the performance of advanced ceramics is expected to rise. This growth is also indicative of the broader trend towards the adoption of advanced materials in manufacturing and technology sectors, where the emphasis is on achieving greater efficiency, durability, and functionality. The projected growth of the market highlights the importance of continued research and development in surface treatment technologies to meet the evolving needs of industries relying on advanced ceramic parts.

| Report Metric | Details |

| Report Name | Surface Treatment for Advanced Ceramic Parts Market |

| Accounted market size in year | US$ 910 million |

| Forecasted market size in 2031 | US$ 1369 million |

| CAGR | 6.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Anhui Ferrotec, Suzhou GEMtek Co, KoMiCo, SHIH HER Technology, KTT Precision, Shanghai Yingyou Photoelectric Technology, Hefei Veritech, HCUT Semiconductor, WeiZaiCMS, Suzhou Kematek, Pentagon Technologies, Enpro Industries, Ultra Clean Holdings, TOCALO Co., Ltd., Cleanpart, CINOS, Hansol IONES, WONIK QnC, DFtech, TOPWINTECH, FEMVIX, SEWON HARDFACING CO.,LTD, Frontken Corporation, Value Engineering Co., Ltd, Hung Jie Technology Corporation, Alumiplate, Oerlikon Balzers, Beneq, APS Materials, Inc., SilcoTek, Alcadyne, Asset Solutions, Jiangsu KVTS, Shanghai Companion, Kuritec Service Co., Ltd, Wuhu Tongchao Precision Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |