What is Global CNC Cutting Fluid Market?

The Global CNC Cutting Fluid Market is a specialized segment within the broader industrial fluids industry, focusing on fluids used in computer numerical control (CNC) machining processes. These fluids, often referred to as coolants or lubricants, play a crucial role in the machining process by reducing heat and friction between the cutting tool and the workpiece. This not only extends the life of the cutting tools but also enhances the quality of the finished product by preventing overheating and deformation. The market for CNC cutting fluids is driven by the increasing demand for precision engineering and high-quality surface finishes in industries such as automotive, aerospace, and machinery manufacturing. As industries continue to advance technologically, the need for efficient and effective cutting fluids becomes more pronounced. The market is characterized by a variety of fluid types, including oil-based, water-based, and synthetic fluids, each offering distinct advantages depending on the specific machining requirements. With the ongoing trend towards automation and precision in manufacturing, the Global CNC Cutting Fluid Market is poised for continued growth and innovation.

Oil-based Cutting Fluid, Water-based Cutting Fluid in the Global CNC Cutting Fluid Market:

Oil-based cutting fluids are a significant component of the Global CNC Cutting Fluid Market, known for their excellent lubrication properties. These fluids are primarily composed of mineral oils or petroleum-based oils, often enhanced with additives to improve performance. The primary advantage of oil-based cutting fluids is their ability to provide superior lubrication, which reduces friction and wear on cutting tools. This is particularly beneficial in heavy-duty machining operations where high temperatures and pressures are common. Oil-based fluids also offer good corrosion protection, which is essential for maintaining the integrity of both the tools and the workpieces. However, they can be more challenging to manage in terms of disposal and environmental impact, as they are not as easily biodegradable as their water-based counterparts. On the other hand, water-based cutting fluids, also known as water-soluble or emulsifiable oils, are gaining popularity due to their environmental benefits and cost-effectiveness. These fluids are typically a mixture of water and oil, with the oil being emulsified in the water. The high water content provides excellent cooling properties, which is crucial for dissipating the heat generated during machining. This makes water-based fluids ideal for high-speed machining operations where heat management is critical. Additionally, they are generally less expensive than oil-based fluids and easier to clean up, reducing the overall maintenance costs. However, water-based fluids may not provide the same level of lubrication as oil-based fluids, which can be a drawback in certain applications. Despite this, advancements in formulation technology have led to the development of water-based fluids with enhanced lubrication properties, making them a viable option for a wider range of machining processes. Both oil-based and water-based cutting fluids have their unique advantages and limitations, and the choice between them often depends on the specific requirements of the machining operation, including the type of material being machined, the speed and feed rates, and the desired surface finish. As the Global CNC Cutting Fluid Market continues to evolve, manufacturers are focusing on developing cutting fluids that offer a balance of lubrication, cooling, and environmental sustainability to meet the diverse needs of modern machining operations.

Machinery Manufacturing, Automobile, Aerospace, Other in the Global CNC Cutting Fluid Market:

The usage of CNC cutting fluids in machinery manufacturing is pivotal for ensuring the efficiency and longevity of machining processes. In this sector, cutting fluids are used to cool and lubricate the cutting tools and workpieces, reducing friction and wear. This is crucial for maintaining the precision and accuracy of the machined components, which are often used in complex machinery assemblies. The use of cutting fluids also helps in achieving high-quality surface finishes, which is essential for the performance and reliability of the machinery. In the automobile industry, CNC cutting fluids play a vital role in the production of various components, including engine parts, transmission systems, and body panels. The fluids help in maintaining the dimensional accuracy and surface integrity of these components, which is critical for the overall performance and safety of the vehicles. The aerospace industry, known for its stringent quality standards and precision requirements, relies heavily on CNC cutting fluids to achieve the desired level of accuracy and surface finish. The fluids help in managing the heat generated during the machining of high-strength materials like titanium and composites, which are commonly used in aerospace applications. This ensures that the components meet the necessary specifications and performance criteria. In addition to these industries, CNC cutting fluids are also used in other sectors such as electronics, medical devices, and energy, where precision machining is required. In these applications, cutting fluids help in achieving the desired level of accuracy and surface finish, while also extending the life of the cutting tools. As industries continue to advance technologically, the demand for high-performance cutting fluids is expected to grow, driving innovation and development in the Global CNC Cutting Fluid Market.

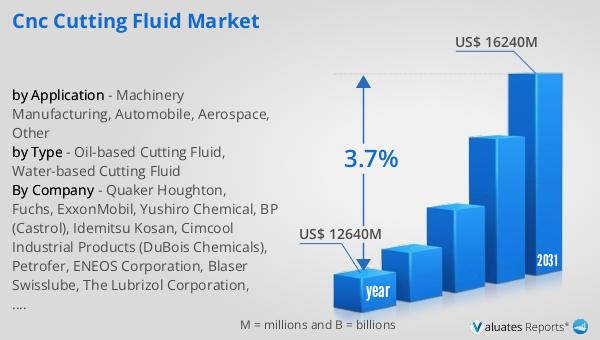

Global CNC Cutting Fluid Market Outlook:

The global market for CNC Cutting Fluid was valued at approximately $12.64 billion in 2024, with projections indicating a growth to around $16.24 billion by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 3.7% over the forecast period. This steady increase in market size underscores the rising demand for CNC cutting fluids across various industries, driven by the need for precision machining and high-quality surface finishes. The market's expansion is fueled by advancements in manufacturing technologies and the increasing adoption of CNC machines in sectors such as automotive, aerospace, and machinery manufacturing. As these industries continue to evolve, the demand for efficient and effective cutting fluids is expected to rise, contributing to the overall growth of the market. The projected growth also reflects the ongoing trend towards automation and precision in manufacturing, which necessitates the use of high-performance cutting fluids to ensure optimal machining results. As a result, the Global CNC Cutting Fluid Market is poised for continued growth and development, with manufacturers focusing on innovation and sustainability to meet the evolving needs of modern machining operations.

| Report Metric | Details |

| Report Name | CNC Cutting Fluid Market |

| Accounted market size in year | US$ 12640 million |

| Forecasted market size in 2031 | US$ 16240 million |

| CAGR | 3.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Quaker Houghton, Fuchs, ExxonMobil, Yushiro Chemical, BP (Castrol), Idemitsu Kosan, Cimcool Industrial Products (DuBois Chemicals), Petrofer, ENEOS Corporation, Blaser Swisslube, The Lubrizol Corporation, Valvoline, TotalEnergies, Indian Oil, Anmei Technology Co., Ltd., Frank Technology (Shenzhen) Co., Ltd., COSMO Oil, Sinopec, Chevron, Talent Bioengineering Co., Ltd., LUKOIL, Mecom Industries, Hindustan Petroleum Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |