What is Global SBR for Lithium Battery Adhesives Market?

The Global SBR for Lithium Battery Adhesives Market refers to the worldwide industry focused on the production and application of Styrene-Butadiene Rubber (SBR) as an adhesive component in lithium battery manufacturing. SBR is a synthetic rubber that is highly valued for its adhesive properties, flexibility, and resistance to abrasion, making it an ideal choice for use in lithium batteries. These batteries are essential in powering a wide range of electronic devices, from smartphones to electric vehicles, due to their high energy density and long life cycle. The market for SBR in this context is driven by the increasing demand for lithium batteries, which is fueled by the growing adoption of electric vehicles and renewable energy storage solutions. As the world shifts towards more sustainable energy sources, the need for efficient and reliable battery technology becomes more critical, thereby boosting the demand for high-quality adhesives like SBR. This market is characterized by continuous innovation and development, as manufacturers strive to enhance the performance and efficiency of lithium batteries through improved adhesive solutions. The global reach of this market underscores its importance in the broader context of technological advancement and environmental sustainability.

SBR, E-SBR, S-SBR in the Global SBR for Lithium Battery Adhesives Market:

SBR, or Styrene-Butadiene Rubber, is a synthetic rubber that plays a crucial role in the Global SBR for Lithium Battery Adhesives Market. It is known for its excellent adhesive properties, flexibility, and resistance to wear and tear, making it a preferred choice for use in lithium battery manufacturing. There are two main types of SBR used in this market: Emulsion SBR (E-SBR) and Solution SBR (S-SBR). E-SBR is produced through an emulsion polymerization process, which involves the polymerization of styrene and butadiene in an aqueous medium. This type of SBR is known for its good abrasion resistance and aging stability, making it suitable for use in various applications, including lithium battery adhesives. On the other hand, S-SBR is produced through a solution polymerization process, which allows for better control over the polymer structure and properties. This results in a rubber with superior performance characteristics, such as enhanced tensile strength and improved heat resistance. In the context of lithium battery adhesives, S-SBR is often preferred for its ability to provide stronger and more durable bonds, which are essential for the long-term performance and reliability of the batteries. The choice between E-SBR and S-SBR depends on the specific requirements of the battery application, as well as factors such as cost and availability. In recent years, there has been a growing trend towards the use of S-SBR in lithium battery adhesives, driven by the increasing demand for high-performance batteries in applications such as electric vehicles and renewable energy storage. This trend is expected to continue as manufacturers seek to enhance the performance and efficiency of their battery products through the use of advanced adhesive solutions. Overall, the Global SBR for Lithium Battery Adhesives Market is characterized by a dynamic interplay between technological innovation, market demand, and environmental considerations, as stakeholders work to develop and implement more sustainable and efficient battery technologies.

Single Layer Lithium Battery, Double Layer Lithium Battery in the Global SBR for Lithium Battery Adhesives Market:

The usage of Global SBR for Lithium Battery Adhesives Market in single-layer and double-layer lithium batteries is a critical aspect of modern battery technology. In single-layer lithium batteries, SBR is used as an adhesive to bond the various components of the battery together, ensuring structural integrity and reliable performance. The adhesive properties of SBR help to maintain the alignment and positioning of the battery components, which is essential for efficient energy transfer and overall battery performance. The flexibility and durability of SBR also contribute to the longevity of single-layer lithium batteries, as they help to absorb and dissipate mechanical stresses that can occur during battery operation. In double-layer lithium batteries, SBR plays a similar role, but with additional considerations due to the more complex structure of these batteries. Double-layer lithium batteries consist of two layers of active material, which are separated by a thin layer of electrolyte. The use of SBR as an adhesive in these batteries helps to ensure that the layers remain securely bonded, preventing delamination and ensuring consistent performance. The adhesive properties of SBR also help to maintain the integrity of the electrolyte layer, which is critical for the efficient operation of double-layer lithium batteries. In both single-layer and double-layer lithium batteries, the choice of SBR as an adhesive is driven by its ability to provide strong and durable bonds, as well as its resistance to chemical and thermal degradation. This makes SBR an ideal choice for use in high-performance battery applications, where reliability and longevity are critical considerations. As the demand for advanced battery technologies continues to grow, the role of SBR in lithium battery adhesives is expected to become increasingly important, as manufacturers seek to develop more efficient and sustainable battery solutions.

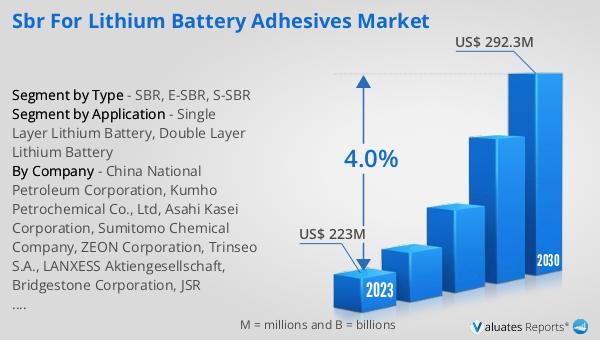

Global SBR for Lithium Battery Adhesives Market Outlook:

The global market for SBR for Lithium Battery Adhesives was valued at $239 million in 2024, and it is anticipated to expand to a revised size of $314 million by 2031, reflecting a compound annual growth rate (CAGR) of 4.0% over the forecast period. This growth trajectory underscores the increasing demand for SBR in the production of lithium battery adhesives, driven by the rising adoption of electric vehicles and renewable energy storage solutions. As the world continues to transition towards more sustainable energy sources, the need for efficient and reliable battery technology becomes more critical, thereby boosting the demand for high-quality adhesives like SBR. The market's expansion is also indicative of the ongoing innovation and development within the industry, as manufacturers strive to enhance the performance and efficiency of lithium batteries through improved adhesive solutions. The projected growth of the market highlights the importance of SBR in the broader context of technological advancement and environmental sustainability, as stakeholders work to develop and implement more sustainable and efficient battery technologies. This market outlook reflects the dynamic interplay between technological innovation, market demand, and environmental considerations, as the global community seeks to address the challenges and opportunities presented by the transition to a more sustainable energy future.

| Report Metric | Details |

| Report Name | SBR for Lithium Battery Adhesives Market |

| Accounted market size in year | US$ 239 million |

| Forecasted market size in 2031 | US$ 314 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | China National Petroleum Corporation, Kumho Petrochemical Co., Ltd, Asahi Kasei Corporation, Sumitomo Chemical Company, ZEON Corporation, Trinseo S.A., LANXESS Aktiengesellschaft, Bridgestone Corporation, JSR Corporation, The Goodyear Tire & Rubber Company, Sinopec, Zhejiang Vitile Co., Ltd, Jiangsu Shenhua Chemical Co., Ltd, Zhechen Rubber, Fujian FuXiang Chemical Co., Ltd, PJSC Nizhnekamsk, Chandra Asri, Lion Elastomer, SRI Group, Versalis, Michelin, SIBUR, LG Chemicals, Dynasol Elastomer |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |