What is Global GaN Wafer Inspection and Review System Market?

The Global GaN Wafer Inspection and Review System Market is a specialized segment within the semiconductor industry that focuses on the inspection and analysis of Gallium Nitride (GaN) wafers. GaN is a semiconductor material that has gained significant attention due to its superior properties, such as high electron mobility, thermal stability, and efficiency in power conversion. These characteristics make GaN an ideal choice for applications in power electronics, radio frequency (RF) components, and light-emitting diodes (LEDs). The inspection and review systems are crucial for ensuring the quality and reliability of GaN wafers, as they help identify defects and irregularities that could affect the performance of the final products. These systems employ advanced technologies, including optical and electron microscopy, to provide detailed analysis and feedback during the manufacturing process. As the demand for high-performance electronic devices continues to grow, the GaN Wafer Inspection and Review System Market is expected to expand, driven by the need for precision and efficiency in semiconductor manufacturing. The market's growth is further supported by ongoing advancements in inspection technologies, which enhance the accuracy and speed of defect detection and analysis.

GaN Patterned Inspection System, GaN Unpatterned Inspection System in the Global GaN Wafer Inspection and Review System Market:

The GaN Patterned Inspection System and GaN Unpatterned Inspection System are two critical components of the Global GaN Wafer Inspection and Review System Market. The GaN Patterned Inspection System is designed to examine wafers that have undergone a patterning process, which involves creating specific designs or structures on the wafer surface. This system uses advanced imaging techniques to detect defects such as pattern misalignment, bridging, and missing patterns. It is essential for ensuring that the intricate designs on the wafer are accurately formed, as any defects can lead to significant performance issues in the final semiconductor devices. The system's ability to provide high-resolution images and precise measurements makes it an invaluable tool for manufacturers aiming to maintain high-quality standards. On the other hand, the GaN Unpatterned Inspection System focuses on wafers that have not yet been patterned. This system is crucial for identifying defects that occur during the initial stages of wafer production, such as cracks, scratches, and contamination. By detecting these issues early in the manufacturing process, the unpatterned inspection system helps prevent costly rework and ensures that only high-quality wafers proceed to the patterning stage. The system employs various inspection methods, including optical and electron microscopy, to provide comprehensive analysis and feedback to manufacturers. Both the patterned and unpatterned inspection systems play a vital role in the overall quality control process of GaN wafer production. They help manufacturers identify and address defects at different stages of the production process, ensuring that the final products meet the required performance and reliability standards. As the demand for GaN-based devices continues to rise, the importance of these inspection systems in maintaining product quality and efficiency cannot be overstated. The integration of advanced technologies, such as artificial intelligence and machine learning, into these inspection systems is further enhancing their capabilities. These technologies enable the systems to learn from previous inspections, improving their accuracy and efficiency over time. This continuous improvement is crucial for keeping up with the increasing complexity of semiconductor devices and the growing demand for high-performance electronic components. In summary, the GaN Patterned Inspection System and GaN Unpatterned Inspection System are essential components of the Global GaN Wafer Inspection and Review System Market. They provide manufacturers with the tools needed to ensure the quality and reliability of GaN wafers, which are critical for the production of high-performance electronic devices. As the market continues to grow, driven by advancements in inspection technologies and increasing demand for GaN-based products, these systems will play an increasingly important role in the semiconductor industry.

GaN RF, GaN Power, HB GaN LED in the Global GaN Wafer Inspection and Review System Market:

The Global GaN Wafer Inspection and Review System Market plays a crucial role in several key areas, including GaN RF, GaN Power, and HB GaN LED applications. In the GaN RF domain, GaN wafers are used to produce high-frequency radio frequency components that are essential for wireless communication systems, radar, and satellite communications. The inspection and review systems ensure that the GaN wafers used in these applications are free from defects that could compromise their performance. By providing detailed analysis and feedback, these systems help manufacturers produce high-quality RF components that meet the stringent requirements of the telecommunications industry. In the GaN Power sector, GaN wafers are used to create power electronic devices that offer superior efficiency and performance compared to traditional silicon-based devices. These devices are used in a wide range of applications, including power converters, inverters, and motor drives. The inspection and review systems are critical for ensuring that the GaN wafers used in these applications meet the necessary quality standards. By detecting defects early in the manufacturing process, these systems help prevent costly rework and ensure that the final products deliver the expected performance and reliability. The HB GaN LED market is another area where the Global GaN Wafer Inspection and Review System Market is making a significant impact. GaN wafers are used to produce high-brightness LEDs that are used in a variety of applications, including lighting, displays, and automotive lighting. The inspection and review systems play a vital role in ensuring that the GaN wafers used in these applications are of the highest quality. By identifying defects and irregularities, these systems help manufacturers produce LEDs that offer superior brightness, efficiency, and longevity. Overall, the Global GaN Wafer Inspection and Review System Market is essential for ensuring the quality and reliability of GaN-based products in the RF, power, and LED sectors. As the demand for high-performance electronic devices continues to grow, the importance of these inspection systems in maintaining product quality and efficiency cannot be overstated. By providing manufacturers with the tools needed to identify and address defects early in the production process, these systems help ensure that the final products meet the required performance and reliability standards.

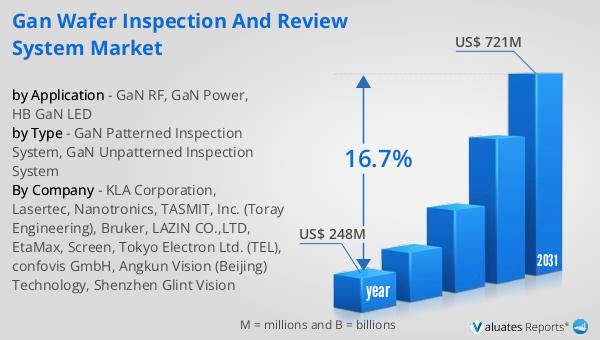

Global GaN Wafer Inspection and Review System Market Outlook:

The global market for GaN Wafer Inspection and Review System was valued at $248 million in 2024 and is anticipated to grow significantly, reaching an estimated size of $721 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 16.7% over the forecast period. This impressive growth rate underscores the increasing demand for GaN wafer inspection systems, driven by the expanding applications of GaN technology in various sectors such as telecommunications, power electronics, and lighting. The market's expansion is fueled by the need for high-quality, reliable GaN wafers that meet the stringent performance requirements of modern electronic devices. As the semiconductor industry continues to evolve, the importance of GaN wafer inspection and review systems in ensuring product quality and efficiency becomes increasingly apparent. These systems provide manufacturers with the tools needed to identify and address defects early in the production process, helping to prevent costly rework and ensure that the final products meet the required performance and reliability standards. The integration of advanced technologies, such as artificial intelligence and machine learning, into these systems is further enhancing their capabilities, enabling them to keep pace with the increasing complexity of semiconductor devices. In summary, the global market for GaN Wafer Inspection and Review System is poised for significant growth over the coming years, driven by the expanding applications of GaN technology and the increasing demand for high-quality, reliable electronic devices. As the market continues to evolve, the importance of these inspection systems in maintaining product quality and efficiency cannot be overstated.

| Report Metric | Details |

| Report Name | GaN Wafer Inspection and Review System Market |

| Accounted market size in year | US$ 248 million |

| Forecasted market size in 2031 | US$ 721 million |

| CAGR | 16.7% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | KLA Corporation, Lasertec, Nanotronics, TASMIT, Inc. (Toray Engineering), Bruker, LAZIN CO.,LTD, EtaMax, Screen, Tokyo Electron Ltd. (TEL), confovis GmbH, Angkun Vision (Beijing) Technology, Shenzhen Glint Vision |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |