What is Global Flexible PCB Cover Layer Market?

The Global Flexible PCB Cover Layer Market is a specialized segment within the electronics industry that focuses on the production and distribution of cover layers used in flexible printed circuit boards (FPCBs). These cover layers are essential components that protect the delicate circuitry of FPCBs from environmental damage, mechanical stress, and electrical interference. Flexible PCBs are widely used in various electronic devices due to their ability to bend and conform to different shapes, making them ideal for compact and complex electronic designs. The cover layer acts as a protective shield, ensuring the longevity and reliability of the circuits. The market for these cover layers is driven by the increasing demand for flexible electronics in consumer gadgets, automotive applications, medical devices, and industrial equipment. As technology advances, the need for more durable and efficient cover layers grows, prompting manufacturers to innovate and develop new materials and processes. The market is characterized by a diverse range of products, including different types of cover layers such as polyimide, polyester, and others, each offering unique properties to meet specific application requirements. The Global Flexible PCB Cover Layer Market is poised for growth as industries continue to adopt flexible electronics for their versatility and performance benefits.

Yellow Cover Layer, Black Cover Layer, Others in the Global Flexible PCB Cover Layer Market:

In the Global Flexible PCB Cover Layer Market, various types of cover layers are utilized to meet the specific needs of different applications. Among these, the Yellow Cover Layer is one of the most commonly used due to its excellent thermal stability and electrical insulation properties. It is typically made from polyimide materials, which provide a robust protective layer for flexible circuits. The yellow color is often associated with its ability to withstand high temperatures, making it suitable for applications in harsh environments. On the other hand, the Black Cover Layer is preferred for its aesthetic appeal and UV resistance. It is often used in consumer electronics where the appearance of the circuit board is a consideration. The black color also helps in reducing light reflection, which can be crucial in certain optical applications. Additionally, the black cover layer offers good thermal management properties, which are essential in high-performance electronic devices. Apart from these, there are other types of cover layers available in the market, each designed to cater to specific requirements. For instance, some cover layers are engineered to provide enhanced flexibility, allowing the circuit to bend and twist without compromising its integrity. Others may focus on providing superior chemical resistance, making them ideal for use in environments where exposure to corrosive substances is a concern. The choice of cover layer depends on various factors, including the operating environment, mechanical stress, and electrical performance requirements. Manufacturers in the Global Flexible PCB Cover Layer Market are continually innovating to develop new materials and technologies that can offer improved performance and reliability. This includes the development of cover layers with advanced features such as self-healing properties, which can automatically repair minor damages, and conductive cover layers that can enhance the electrical performance of the circuit. As the demand for flexible electronics continues to grow, the market for flexible PCB cover layers is expected to expand, with new opportunities emerging in various industries. The ongoing research and development efforts in this field are likely to result in the introduction of more advanced and versatile cover layer solutions, further driving the growth of the market.

Single Sided FPC, Double Sided FPC in the Global Flexible PCB Cover Layer Market:

The Global Flexible PCB Cover Layer Market plays a crucial role in the production of Single Sided and Double Sided Flexible Printed Circuits (FPCs). Single Sided FPCs are the simplest form of flexible circuits, consisting of a single conductive layer on a flexible substrate. The cover layer in these circuits serves as a protective barrier, shielding the conductive traces from environmental factors such as moisture, dust, and mechanical abrasion. This protection is vital in ensuring the reliability and longevity of the circuit, especially in applications where the circuit is exposed to harsh conditions. Single Sided FPCs are commonly used in applications where space is limited, and flexibility is required, such as in wearable devices, mobile phones, and compact electronic gadgets. The cover layer not only provides protection but also contributes to the overall flexibility of the circuit, allowing it to bend and conform to the desired shape without breaking. In Double Sided FPCs, the cover layer plays an even more critical role. These circuits have conductive layers on both sides of the substrate, allowing for more complex circuit designs and increased functionality. The cover layer in Double Sided FPCs must provide insulation between the two conductive layers while also offering protection from external factors. This requires the cover layer to have excellent dielectric properties and mechanical strength. Double Sided FPCs are used in more demanding applications where higher circuit density and performance are required, such as in automotive electronics, medical devices, and industrial equipment. The cover layer in these circuits must be able to withstand higher levels of mechanical stress and thermal cycling, ensuring the circuit's performance and reliability over its lifespan. The choice of cover layer material is crucial in both Single Sided and Double Sided FPCs, as it directly impacts the circuit's performance, durability, and flexibility. Manufacturers in the Global Flexible PCB Cover Layer Market offer a wide range of materials and solutions to meet the diverse needs of these applications. As technology advances and the demand for flexible electronics continues to grow, the market for flexible PCB cover layers is expected to expand, with new opportunities emerging in various industries. The ongoing research and development efforts in this field are likely to result in the introduction of more advanced and versatile cover layer solutions, further driving the growth of the market.

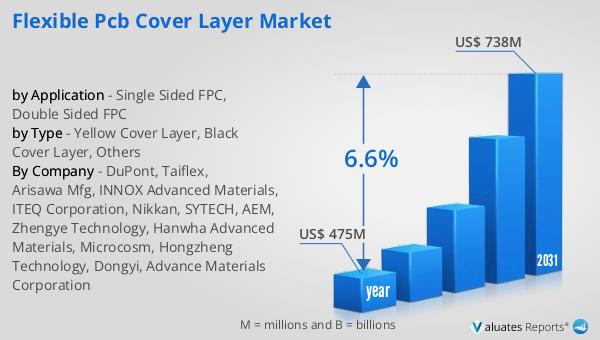

Global Flexible PCB Cover Layer Market Outlook:

The global market for Flexible PCB Cover Layer, valued at $475 million in 2024, is anticipated to grow significantly, reaching an estimated size of $738 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.6% over the forecast period. This upward trend is indicative of the increasing demand for flexible electronics across various sectors, including consumer electronics, automotive, and healthcare. The flexibility and durability offered by these cover layers make them indispensable in the production of advanced electronic devices that require compact and reliable circuit solutions. As industries continue to innovate and integrate more sophisticated technologies, the need for high-quality flexible PCB cover layers is expected to rise. This growth is further fueled by the ongoing advancements in material science and manufacturing processes, which are enabling the development of cover layers with enhanced properties such as improved thermal management, chemical resistance, and mechanical strength. The market's expansion is also supported by the growing trend towards miniaturization and the increasing adoption of flexible electronics in emerging applications. As a result, manufacturers are investing in research and development to create new and improved cover layer solutions that can meet the evolving demands of the market. This dynamic environment presents numerous opportunities for growth and innovation in the Global Flexible PCB Cover Layer Market.

| Report Metric | Details |

| Report Name | Flexible PCB Cover Layer Market |

| Accounted market size in year | US$ 475 million |

| Forecasted market size in 2031 | US$ 738 million |

| CAGR | 6.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DuPont, Taiflex, Arisawa Mfg, INNOX Advanced Materials, ITEQ Corporation, Nikkan, SYTECH, AEM, Zhengye Technology, Hanwha Advanced Materials, Microcosm, Hongzheng Technology, Dongyi, Advance Materials Corporation |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |