What is Global Advanced Ceramic Parts Surface Treatment Market?

The Global Advanced Ceramic Parts Surface Treatment Market is a specialized sector focusing on enhancing the surface properties of ceramic components used in various industries. Advanced ceramics are known for their exceptional properties such as high temperature resistance, mechanical strength, and chemical stability. However, to further improve their performance and extend their lifespan, surface treatments are applied. These treatments can include processes like coating, polishing, and cleaning, which help in reducing wear and tear, improving thermal and electrical conductivity, and enhancing resistance to corrosion and chemical attacks. The market for these treatments is driven by the increasing demand for advanced ceramics in industries such as electronics, automotive, aerospace, and healthcare. As these industries continue to evolve and require materials that can withstand extreme conditions, the need for effective surface treatment solutions becomes more critical. The market is characterized by continuous innovation and technological advancements aimed at developing more efficient and cost-effective treatment processes. Companies operating in this market are investing in research and development to create new treatment methods that can meet the specific needs of different applications. Overall, the Global Advanced Ceramic Parts Surface Treatment Market plays a crucial role in ensuring the reliability and durability of ceramic components used in high-performance applications.

Precision Cleaning, Coating, Anodizing, Others in the Global Advanced Ceramic Parts Surface Treatment Market:

Precision cleaning, coating, anodizing, and other surface treatment processes are integral to the Global Advanced Ceramic Parts Surface Treatment Market. Precision cleaning is a meticulous process that removes contaminants from ceramic surfaces to ensure optimal performance. This is particularly important in industries like semiconductors and aerospace, where even the smallest impurity can lead to significant performance issues. The cleaning process often involves the use of specialized solvents and equipment to achieve the desired level of cleanliness. Coating, on the other hand, involves applying a layer of material onto the ceramic surface to enhance its properties. This can include improving wear resistance, reducing friction, or providing a barrier against environmental factors. Various types of coatings are used, including thermal spray coatings, chemical vapor deposition, and physical vapor deposition, each offering unique benefits depending on the application. Anodizing is another surface treatment process that involves creating an oxide layer on the surface of the ceramic part. This layer can improve corrosion resistance and enhance the aesthetic appearance of the component. Anodizing is commonly used in the automotive and aerospace industries, where components are exposed to harsh environments. Other surface treatment processes include polishing, which improves the surface finish and reduces surface roughness, and laser treatment, which can modify the surface properties at a microscopic level. Each of these processes plays a vital role in enhancing the performance and longevity of advanced ceramic parts. The choice of treatment depends on the specific requirements of the application, and often, a combination of different processes is used to achieve the desired results. As the demand for advanced ceramics continues to grow, the need for innovative and efficient surface treatment solutions will also increase, driving further advancements in this market.

Semiconductor, Display Panel in the Global Advanced Ceramic Parts Surface Treatment Market:

The Global Advanced Ceramic Parts Surface Treatment Market finds significant applications in the semiconductor and display panel industries. In the semiconductor industry, advanced ceramics are used in various components such as wafer carriers, insulators, and substrates. These components require precise surface treatment to ensure high performance and reliability. Precision cleaning is crucial in this context, as any contamination on the ceramic surface can lead to defects in the semiconductor devices. Coating processes are also employed to enhance the thermal and electrical properties of ceramic components, which is essential for the efficient functioning of semiconductor devices. Anodizing and other surface treatments help in improving the durability and lifespan of these components, which are often subjected to extreme conditions during the manufacturing process. In the display panel industry, advanced ceramics are used in components such as substrates and protective coatings. Surface treatments are applied to enhance the optical properties of these components, ensuring high clarity and brightness of the display panels. Coating processes are particularly important in this industry, as they help in reducing glare and improving the scratch resistance of the display surfaces. Precision cleaning is also essential to remove any impurities that could affect the quality of the display. The demand for advanced ceramic parts with superior surface properties is increasing in both the semiconductor and display panel industries, driven by the need for high-performance and reliable components. As these industries continue to evolve and adopt new technologies, the role of surface treatment processes in enhancing the performance of ceramic components will become even more critical. Companies operating in the Global Advanced Ceramic Parts Surface Treatment Market are focusing on developing innovative solutions to meet the specific needs of these industries, ensuring that they can deliver components that meet the highest standards of quality and performance.

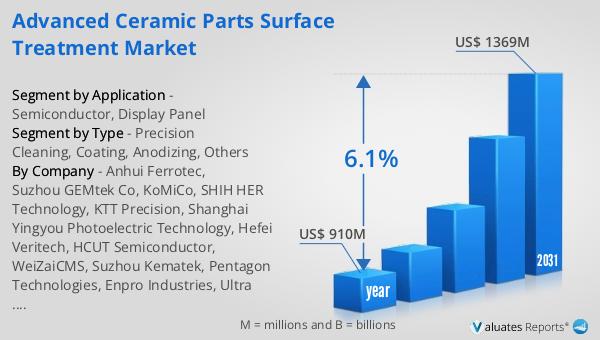

Global Advanced Ceramic Parts Surface Treatment Market Outlook:

In 2024, the global market for Advanced Ceramic Parts Surface Treatment was valued at approximately $910 million. This market is anticipated to grow significantly, reaching an estimated size of $1,369 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 6.1% over the forecast period. The increasing demand for advanced ceramics in various industries, such as electronics, automotive, and aerospace, is a key driver of this market growth. As these industries continue to seek materials that offer superior performance and durability, the need for effective surface treatment solutions becomes more pronounced. Surface treatments play a crucial role in enhancing the properties of ceramic components, making them more suitable for high-performance applications. The market is characterized by continuous innovation and technological advancements, with companies investing in research and development to create more efficient and cost-effective treatment processes. As a result, the Global Advanced Ceramic Parts Surface Treatment Market is poised for significant growth, driven by the increasing demand for high-quality ceramic components in various industries. This growth presents opportunities for companies operating in this market to expand their product offerings and capture a larger share of the market.

| Report Metric | Details |

| Report Name | Advanced Ceramic Parts Surface Treatment Market |

| Accounted market size in year | US$ 910 million |

| Forecasted market size in 2031 | US$ 1369 million |

| CAGR | 6.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | Anhui Ferrotec, Suzhou GEMtek Co, KoMiCo, SHIH HER Technology, KTT Precision, Shanghai Yingyou Photoelectric Technology, Hefei Veritech, HCUT Semiconductor, WeiZaiCMS, Suzhou Kematek, Pentagon Technologies, Enpro Industries, Ultra Clean Holdings, TOCALO Co., Ltd., Cleanpart, CINOS, Hansol IONES, WONIK QnC, DFtech, TOPWINTECH, FEMVIX, SEWON HARDFACING CO.,LTD, Frontken Corporation, Value Engineering Co., Ltd, Hung Jie Technology Corporation, Alumiplate, Oerlikon Balzers, Beneq, APS Materials, Inc., SilcoTek, Alcadyne, Asset Solutions, Jiangsu KVTS, Shanghai Companion, Kuritec Service Co., Ltd, Wuhu Tongchao Precision Machinery |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |