What is Global Electroless UBM Plating Service Market?

The Global Electroless UBM (Under Bump Metallization) Plating Service Market is a specialized segment within the broader semiconductor industry, focusing on the application of electroless plating techniques to create a metal layer on semiconductor wafers. This process is crucial for the development of reliable and efficient electronic components, as it enhances the adhesion and conductivity of the metal layers used in semiconductor devices. Electroless UBM plating is a chemical deposition process that does not require an external power source, making it a cost-effective and uniform method for coating complex surfaces. The market for these services is driven by the increasing demand for advanced electronic devices, which require high-performance and miniaturized components. As technology continues to evolve, the need for precise and efficient plating solutions becomes more critical, positioning the Global Electroless UBM Plating Service Market as a key player in the semiconductor manufacturing landscape. This market is characterized by continuous innovation and adaptation to meet the ever-changing requirements of the electronics industry, ensuring that it remains a vital component of the global technology ecosystem.

in the Global Electroless UBM Plating Service Market:

The Global Electroless UBM Plating Service Market caters to a diverse range of customers, each with specific needs and applications for electroless plating. One of the primary types of electroless UBM plating is nickel-based plating, which is widely used due to its excellent corrosion resistance and ability to provide a strong bond between the semiconductor and the metal layer. This type of plating is particularly popular in applications where durability and longevity are critical, such as in automotive electronics and industrial machinery. Another common type is copper-based plating, which is favored for its superior electrical conductivity. Copper plating is often used in high-frequency applications, such as in telecommunications and data transmission, where minimizing signal loss is essential. Additionally, gold-based plating is utilized for its exceptional conductivity and resistance to oxidation, making it ideal for high-reliability applications like aerospace and medical devices. Each of these plating types offers unique advantages, allowing customers to select the most appropriate solution based on their specific requirements. The choice of plating type is influenced by factors such as the intended application, environmental conditions, and cost considerations. As the demand for advanced electronic devices continues to grow, the Global Electroless UBM Plating Service Market is expected to expand, offering a wider range of options to meet the diverse needs of its customers. This market is characterized by a high degree of customization, with service providers working closely with clients to develop tailored solutions that address their unique challenges. The ability to offer specialized plating services is a key differentiator in this competitive market, as it allows companies to stand out by providing value-added services that enhance the performance and reliability of their products. Furthermore, advancements in plating technology are enabling the development of new types of electroless UBM plating, such as palladium-based and silver-based options, which offer additional benefits in terms of conductivity and corrosion resistance. These innovations are driving the evolution of the market, ensuring that it remains at the forefront of the semiconductor industry. As a result, the Global Electroless UBM Plating Service Market is poised for continued growth, driven by the increasing demand for high-performance electronic components and the ongoing development of new plating technologies.

Logic, Memory, Power Semiconductors, MEMS, Others in the Global Electroless UBM Plating Service Market:

The Global Electroless UBM Plating Service Market plays a crucial role in various areas of semiconductor applications, including logic, memory, power semiconductors, MEMS (Micro-Electro-Mechanical Systems), and others. In the realm of logic devices, electroless UBM plating is essential for creating reliable connections between the semiconductor die and the package. This process ensures that the electrical signals are transmitted efficiently, which is vital for the performance of processors and other logic components. The uniformity and precision of electroless plating make it an ideal choice for these applications, where even minor defects can lead to significant performance issues. In memory applications, such as DRAM and NAND flash, electroless UBM plating is used to enhance the conductivity and reliability of the connections between memory cells and the rest of the circuit. This is particularly important in high-density memory devices, where the integrity of the connections is critical to maintaining data integrity and performance. Power semiconductors, which are used in applications ranging from power supplies to electric vehicles, also benefit from electroless UBM plating. The process provides a robust and reliable connection that can withstand the high currents and voltages typically encountered in these applications. MEMS devices, which are used in a wide range of applications from sensors to actuators, require precise and reliable connections to function effectively. Electroless UBM plating provides the necessary precision and reliability, ensuring that these devices perform as intended. In addition to these specific applications, electroless UBM plating is also used in a variety of other semiconductor applications, including RF (radio frequency) components and optoelectronics. The versatility and reliability of electroless UBM plating make it an indispensable part of the semiconductor manufacturing process, ensuring that devices meet the high standards required by today's technology-driven world. As the demand for advanced electronic devices continues to grow, the Global Electroless UBM Plating Service Market is expected to expand, offering new opportunities for innovation and growth in the semiconductor industry.

Global Electroless UBM Plating Service Market Outlook:

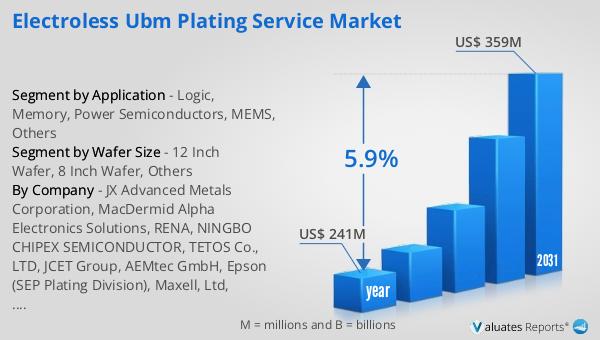

In 2024, the global market for Electroless UBM Plating Service was valued at approximately $241 million. Looking ahead, this market is anticipated to grow significantly, reaching an estimated size of $359 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 5.9% over the forecast period. This upward trend is indicative of the increasing demand for advanced semiconductor components, which rely heavily on electroless UBM plating for enhanced performance and reliability. The market's expansion is driven by the continuous advancements in technology and the growing need for miniaturized and high-performance electronic devices. As industries such as automotive, telecommunications, and consumer electronics continue to evolve, the demand for efficient and reliable plating solutions is expected to rise. This growth is also supported by the increasing adoption of electroless UBM plating in emerging applications, such as the Internet of Things (IoT) and wearable technology, which require compact and efficient components. The market's positive outlook reflects the critical role that electroless UBM plating plays in the semiconductor industry, ensuring that devices meet the high standards required by today's technology-driven world. As a result, the Global Electroless UBM Plating Service Market is poised for continued growth and innovation, offering new opportunities for companies operating in this space.

| Report Metric | Details |

| Report Name | Electroless UBM Plating Service Market |

| Accounted market size in year | US$ 241 million |

| Forecasted market size in 2031 | US$ 359 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Wafer Size |

|

| Segment by Application |

|

| By Region |

|

| By Company | JX Advanced Metals Corporation, MacDermid Alpha Electronics Solutions, RENA, NINGBO CHIPEX SEMICONDUCTOR, TETOS Co., LTD, JCET Group, AEMtec GmbH, Epson (SEP Plating Division), Maxell, Ltd, PacTech, Uyemura, Advafab, Fraunhofer ISIT, AEMtec |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |