What is Global Atmospheric Plasma Spray Coating (APS) Market?

The Global Atmospheric Plasma Spray Coating (APS) Market is a specialized segment within the broader coatings industry, focusing on the application of plasma spray technology to deposit coatings on various substrates. This market is driven by the demand for high-performance coatings that enhance the durability, thermal resistance, and corrosion resistance of components used in diverse industries. APS technology involves the use of a high-temperature plasma jet to melt and propel coating materials onto a substrate, forming a dense and adherent layer. This process is particularly valuable in industries such as aerospace, automotive, electronics, and healthcare, where components are subjected to extreme conditions and require protective coatings to extend their lifespan and performance. The market is characterized by continuous advancements in coating materials and application techniques, aiming to meet the evolving needs of end-users. As industries increasingly prioritize efficiency and sustainability, the APS market is poised for growth, driven by innovations that offer improved coating properties and application efficiencies. The global reach of this market is evident as companies across continents invest in APS technology to enhance their product offerings and maintain a competitive edge in their respective sectors.

Y2O3 Coating, Al2O3 Coating and Others in the Global Atmospheric Plasma Spray Coating (APS) Market:

Yttrium Oxide (Y2O3) coatings, Aluminum Oxide (Al2O3) coatings, and other specialized coatings play a crucial role in the Global Atmospheric Plasma Spray Coating (APS) Market, each offering unique properties that cater to specific industrial needs. Y2O3 coatings are renowned for their exceptional thermal and chemical stability, making them ideal for applications in environments exposed to high temperatures and corrosive substances. These coatings are extensively used in the semiconductor industry, where they protect components from plasma etching and chemical attacks, ensuring the longevity and reliability of semiconductor devices. The high melting point and low thermal conductivity of Y2O3 also make it a preferred choice for thermal barrier coatings in aerospace and power generation applications, where components are subjected to extreme heat. Al2O3 coatings, on the other hand, are valued for their hardness, wear resistance, and electrical insulation properties. These coatings are widely used in the electronics industry to protect sensitive components from wear and electrical interference. In the automotive sector, Al2O3 coatings enhance the durability of engine components and improve fuel efficiency by reducing friction. The versatility of Al2O3 coatings extends to the medical field, where they are used to coat surgical instruments and implants, providing a biocompatible surface that resists corrosion and wear. Beyond Y2O3 and Al2O3, the APS market encompasses a range of other coatings tailored to specific applications. For instance, zirconium oxide (ZrO2) coatings are employed in thermal barrier applications due to their excellent thermal insulation properties. These coatings are crucial in the aerospace industry, where they protect turbine blades and other components from high-temperature oxidation and thermal fatigue. Similarly, tungsten carbide (WC) coatings are used in industries requiring extreme wear resistance, such as mining and oil drilling, where equipment is exposed to abrasive conditions. The development of advanced coating materials and techniques is a key driver of innovation in the APS market. Researchers and manufacturers are continually exploring new compositions and processes to enhance the performance of coatings. For example, the incorporation of nanostructured materials into coatings has shown promise in improving their mechanical and thermal properties. These advancements not only extend the lifespan of coated components but also contribute to energy savings and reduced maintenance costs for end-users. In summary, the Global Atmospheric Plasma Spray Coating (APS) Market is characterized by a diverse range of coatings, each designed to meet the specific demands of various industries. Y2O3 and Al2O3 coatings are among the most prominent, offering unique benefits that enhance the performance and durability of components in challenging environments. As industries continue to evolve and seek more efficient and sustainable solutions, the APS market is expected to grow, driven by ongoing research and development efforts that push the boundaries of coating technology.

Semiconductor Etching Parts, Semiconductor Deposition Equipment Parts in the Global Atmospheric Plasma Spray Coating (APS) Market:

The Global Atmospheric Plasma Spray Coating (APS) Market finds significant applications in the semiconductor industry, particularly in the manufacturing of semiconductor etching parts and deposition equipment parts. In semiconductor etching, components are exposed to highly reactive plasma environments that can cause significant wear and degradation over time. APS coatings, such as Y2O3, provide a robust protective layer that resists chemical attacks and thermal stress, ensuring the longevity and reliability of etching components. These coatings are essential in maintaining the precision and efficiency of etching processes, which are critical for the production of high-performance semiconductor devices. Similarly, in semiconductor deposition equipment, APS coatings play a vital role in protecting components from the harsh conditions encountered during the deposition of thin films. Al2O3 coatings, known for their excellent wear resistance and electrical insulation properties, are commonly used to coat deposition equipment parts. These coatings prevent contamination and ensure the consistent performance of deposition processes, which are crucial for achieving the desired properties of semiconductor films. The use of APS coatings in deposition equipment not only extends the lifespan of components but also enhances the overall efficiency and yield of semiconductor manufacturing. The demand for APS coatings in the semiconductor industry is driven by the increasing complexity and miniaturization of semiconductor devices. As manufacturers strive to produce smaller and more powerful chips, the need for precise and reliable manufacturing processes becomes paramount. APS coatings provide the necessary protection and performance enhancements that enable semiconductor manufacturers to meet these challenges. Moreover, the trend towards more sustainable and energy-efficient manufacturing processes further underscores the importance of APS coatings, as they contribute to reduced maintenance and energy consumption. In conclusion, the Global Atmospheric Plasma Spray Coating (APS) Market plays a critical role in the semiconductor industry, particularly in the protection and enhancement of etching and deposition equipment parts. The unique properties of APS coatings, such as chemical resistance, thermal stability, and wear resistance, make them indispensable in ensuring the reliability and efficiency of semiconductor manufacturing processes. As the semiconductor industry continues to evolve and face new challenges, the demand for advanced APS coatings is expected to grow, driven by the need for more precise, efficient, and sustainable manufacturing solutions.

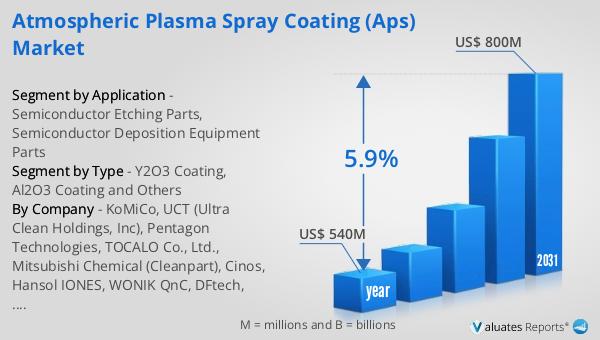

Global Atmospheric Plasma Spray Coating (APS) Market Outlook:

The global market for Atmospheric Plasma Spray Coating (APS) was valued at $540 million in 2024 and is anticipated to expand to a revised size of $800 million by 2031, reflecting a compound annual growth rate (CAGR) of 5.9% over the forecast period. This growth trajectory underscores the increasing demand for high-performance coatings across various industries, driven by the need for enhanced durability, thermal resistance, and corrosion protection. The APS market's expansion is fueled by technological advancements in coating materials and application techniques, which offer improved properties and efficiencies. As industries such as aerospace, automotive, electronics, and healthcare continue to prioritize efficiency and sustainability, the adoption of APS technology is expected to rise. Companies are investing in APS to enhance their product offerings and maintain a competitive edge in their respective sectors. The market's global reach is evident as businesses across continents embrace APS technology to meet the evolving needs of end-users. This growth reflects the broader trend towards more efficient and sustainable industrial processes, where APS coatings play a crucial role in extending the lifespan and performance of components subjected to extreme conditions.

| Report Metric | Details |

| Report Name | Atmospheric Plasma Spray Coating (APS) Market |

| Accounted market size in year | US$ 540 million |

| Forecasted market size in 2031 | US$ 800 million |

| CAGR | 5.9% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | KoMiCo, UCT (Ultra Clean Holdings, Inc), Pentagon Technologies, TOCALO Co., Ltd., Mitsubishi Chemical (Cleanpart), Cinos, Hansol IONES, WONIK QnC, DFtech, TOPWINTECH, Oerlikon Balzers, Frontken Corporation Berhad, Hung Jie Technology Corporation, Jiangsu Kaiweitesi Semiconductor Technology Co., Ltd., HCUT Co., Ltd, Shanghai Companion, Value Engineering Co., Ltd, Chongqing Genori Technology Co., Ltd, Aldon Group, Vivid Inc. |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |