What is Global TGV Glass Core Substrate Market?

The Global TGV (Through Glass Via) Glass Core Substrate Market is an emerging sector within the electronics industry, focusing on the use of glass substrates with through-glass vias for advanced packaging solutions. These substrates are crucial in the miniaturization and enhancement of electronic devices, offering superior electrical performance, thermal management, and mechanical stability. TGV technology involves creating tiny holes in glass substrates, which are then filled with conductive materials to establish electrical connections. This innovation is particularly significant in the production of semiconductors, where it aids in reducing the size of components while improving their efficiency and reliability. The market is driven by the increasing demand for compact, high-performance electronic devices, such as smartphones, tablets, and wearable technology. Additionally, the rise of the Internet of Things (IoT) and advancements in 5G technology are further propelling the need for TGV glass core substrates. As industries continue to push the boundaries of technology, the Global TGV Glass Core Substrate Market is poised for substantial growth, offering new opportunities for innovation and development in electronic packaging solutions.

Coefficient of Thermal Expansion (CTE), above 5 ppm/°C, Coefficient of Thermal Expansion (CTE), below 5 ppm/°C in the Global TGV Glass Core Substrate Market:

The Coefficient of Thermal Expansion (CTE) is a critical property in materials science, particularly in the context of the Global TGV Glass Core Substrate Market. CTE measures how much a material expands or contracts with changes in temperature. In electronic packaging, matching the CTE of different materials is essential to prevent mechanical stress and potential failure during thermal cycling. Materials with a CTE above 5 ppm/°C are considered to have a relatively high expansion rate. In the context of TGV glass core substrates, a higher CTE can be beneficial in applications where the substrate needs to accommodate larger thermal expansions without cracking or delaminating. This is particularly important in environments with significant temperature fluctuations, where the substrate must maintain its structural integrity. On the other hand, materials with a CTE below 5 ppm/°C exhibit minimal expansion with temperature changes. These materials are ideal for applications requiring high dimensional stability and precision, such as in semiconductor manufacturing. In the Global TGV Glass Core Substrate Market, selecting the appropriate CTE is crucial for ensuring the reliability and performance of electronic devices. Manufacturers must carefully consider the thermal expansion properties of their materials to optimize the performance and longevity of their products. The choice between a higher or lower CTE depends on the specific application requirements and the operating environment of the electronic device. For instance, in high-frequency applications, a lower CTE may be preferred to minimize signal loss and maintain electrical performance. Conversely, in applications where mechanical flexibility is more critical, a higher CTE may be advantageous. As the demand for advanced electronic devices continues to grow, the importance of understanding and optimizing CTE in TGV glass core substrates cannot be overstated. This knowledge enables manufacturers to design and produce more reliable, efficient, and durable electronic components, meeting the ever-evolving needs of the global market.

Wafer Level Packaging, Panel Level Packaging in the Global TGV Glass Core Substrate Market:

The Global TGV Glass Core Substrate Market plays a pivotal role in the advancement of Wafer Level Packaging (WLP) and Panel Level Packaging (PLP) technologies. These packaging methods are essential for the miniaturization and performance enhancement of electronic devices. In Wafer Level Packaging, TGV glass core substrates are used to create compact, high-density interconnections between semiconductor chips and the external circuitry. This packaging technique allows for the integration of multiple chips into a single package, reducing the overall size and weight of electronic devices. The use of TGV glass substrates in WLP provides excellent electrical insulation, thermal management, and mechanical stability, making it ideal for high-performance applications such as smartphones, tablets, and wearable technology. Panel Level Packaging, on the other hand, involves the use of larger panels instead of individual wafers for packaging multiple chips simultaneously. This approach offers significant cost advantages by increasing production efficiency and reducing material waste. TGV glass core substrates are particularly beneficial in PLP due to their ability to support large panel sizes while maintaining high precision and reliability. The use of glass substrates in PLP also enhances the thermal and mechanical properties of the package, ensuring the longevity and performance of the electronic device. As the demand for smaller, more powerful electronic devices continues to rise, the Global TGV Glass Core Substrate Market is poised to play an increasingly important role in the development of advanced packaging solutions. By leveraging the unique properties of TGV glass substrates, manufacturers can create more efficient, reliable, and cost-effective electronic components, meeting the growing needs of the global market.

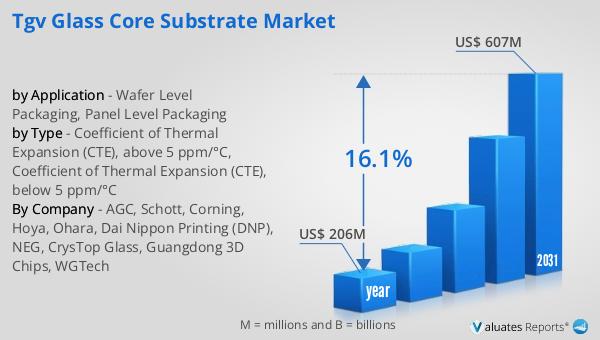

Global TGV Glass Core Substrate Market Outlook:

The global market for TGV Glass Core Substrate was valued at $206 million in 2024 and is anticipated to expand significantly, reaching an estimated $607 million by 2031. This growth trajectory reflects a robust compound annual growth rate (CAGR) of 16.1% over the forecast period. This impressive expansion is driven by the increasing demand for advanced electronic packaging solutions, as industries worldwide seek to enhance the performance and miniaturization of electronic devices. The TGV Glass Core Substrate Market is benefiting from technological advancements and the rising adoption of IoT and 5G technologies, which require high-performance, reliable, and compact electronic components. As the market continues to evolve, manufacturers are focusing on innovation and development to meet the diverse needs of various applications, from consumer electronics to automotive and telecommunications. The projected growth of the TGV Glass Core Substrate Market underscores the importance of this technology in the future of electronic packaging, offering new opportunities for businesses and investors alike. By capitalizing on the unique properties of TGV glass substrates, companies can create cutting-edge solutions that drive the next generation of electronic devices.

| Report Metric | Details |

| Report Name | TGV Glass Core Substrate Market |

| Accounted market size in year | US$ 206 million |

| Forecasted market size in 2031 | US$ 607 million |

| CAGR | 16.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | AGC, Schott, Corning, Hoya, Ohara, Dai Nippon Printing (DNP), NEG, CrysTop Glass, Guangdong 3D Chips, WGTech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |