What is Global Environmentally Friendly Metalworking Fluid Market?

The Global Environmentally Friendly Metalworking Fluid Market is a rapidly evolving sector that focuses on the development and distribution of metalworking fluids designed to minimize environmental impact. These fluids are essential in various industrial processes, such as cutting, grinding, and forming metals, where they serve as coolants and lubricants. Traditional metalworking fluids often contain harmful chemicals that can pose significant environmental and health risks. In contrast, environmentally friendly alternatives are formulated with biodegradable and non-toxic ingredients, reducing their ecological footprint. The market for these sustainable fluids is driven by increasing regulatory pressures, growing awareness of environmental issues, and the demand for safer workplace conditions. Companies are investing in research and development to create innovative products that meet stringent environmental standards while maintaining or enhancing performance. As industries worldwide strive to adopt greener practices, the demand for environmentally friendly metalworking fluids is expected to grow, offering opportunities for businesses to align with sustainability goals and regulatory requirements. This market not only supports environmental conservation but also promotes the health and safety of workers, making it a crucial component of modern industrial operations.

Bio-based Molding Fluid, Bio-based Protective Fluid, Bio-based Cutting Fluid in the Global Environmentally Friendly Metalworking Fluid Market:

Bio-based Molding Fluid, Bio-based Protective Fluid, and Bio-based Cutting Fluid are integral components of the Global Environmentally Friendly Metalworking Fluid Market, each serving distinct purposes in industrial applications. Bio-based Molding Fluids are designed to facilitate the molding process by providing lubrication and cooling, ensuring smooth operations and high-quality outputs. These fluids are derived from renewable resources, such as plant oils, and are engineered to be biodegradable, minimizing their environmental impact. They are particularly beneficial in industries where precision and surface finish are critical, as they help reduce friction and wear on molds, extending their lifespan and improving efficiency. Bio-based Protective Fluids, on the other hand, are formulated to shield metal surfaces from corrosion and oxidation during storage and transportation. These fluids create a protective barrier that prevents moisture and other corrosive elements from damaging the metal, ensuring its integrity and longevity. Like other bio-based fluids, they are made from sustainable sources and are designed to break down naturally, reducing their ecological footprint. Bio-based Cutting Fluids are used in machining processes to cool and lubricate cutting tools, enhancing their performance and extending their service life. These fluids are crucial in maintaining the precision and quality of machined parts, as they help dissipate heat and reduce friction, preventing tool wear and deformation. The use of bio-based cutting fluids is particularly advantageous in high-speed and high-temperature applications, where traditional fluids may fail to provide adequate cooling and lubrication. By opting for bio-based alternatives, industries can reduce their reliance on petroleum-based products and lower their environmental impact, aligning with global sustainability goals. The development and adoption of these bio-based fluids are driven by the increasing demand for environmentally friendly solutions in the metalworking industry. As regulations become more stringent and consumers become more conscious of environmental issues, companies are compelled to innovate and offer products that meet these evolving standards. The transition to bio-based metalworking fluids not only supports environmental conservation but also enhances operational efficiency and worker safety, making it a strategic choice for forward-thinking businesses. By investing in bio-based technologies, companies can differentiate themselves in the market, attract environmentally conscious customers, and contribute to a more sustainable future.

Automotive, Aerospace, Medical Equipment, Precision Machining, Others in the Global Environmentally Friendly Metalworking Fluid Market:

The usage of Global Environmentally Friendly Metalworking Fluid Market spans across various industries, including Automotive, Aerospace, Medical Equipment, Precision Machining, and others, each benefiting from the unique properties of these sustainable fluids. In the Automotive industry, environmentally friendly metalworking fluids are used extensively in the manufacturing and assembly of vehicles. They play a crucial role in processes such as engine block machining, transmission component production, and body panel forming, where they provide essential cooling and lubrication. By opting for eco-friendly fluids, automotive manufacturers can reduce their environmental impact and comply with stringent regulations, while also improving the safety and health conditions for workers. In the Aerospace sector, the precision and reliability of components are paramount, making the use of high-performance metalworking fluids essential. Environmentally friendly options offer the necessary lubrication and cooling for machining complex aerospace parts, such as turbine blades and structural components, while minimizing the risk of contamination and environmental harm. The Medical Equipment industry also benefits from the use of sustainable metalworking fluids, as they are used in the production of surgical instruments, implants, and diagnostic devices. These fluids ensure the precision and cleanliness required in medical applications, while their non-toxic nature aligns with the industry's stringent safety standards. In Precision Machining, where accuracy and surface finish are critical, environmentally friendly metalworking fluids provide the necessary lubrication and cooling to achieve high-quality results. They help reduce tool wear and improve the efficiency of machining processes, making them an ideal choice for manufacturers seeking to enhance their sustainability credentials. Other industries, such as electronics and heavy machinery, also utilize these fluids to improve operational efficiency and reduce their environmental footprint. The adoption of environmentally friendly metalworking fluids across these sectors is driven by the growing awareness of environmental issues and the need to comply with regulatory requirements. By choosing sustainable alternatives, companies can not only reduce their ecological impact but also improve their competitiveness and reputation in the market. The transition to environmentally friendly metalworking fluids represents a significant step towards achieving sustainability goals and promoting a healthier and safer working environment.

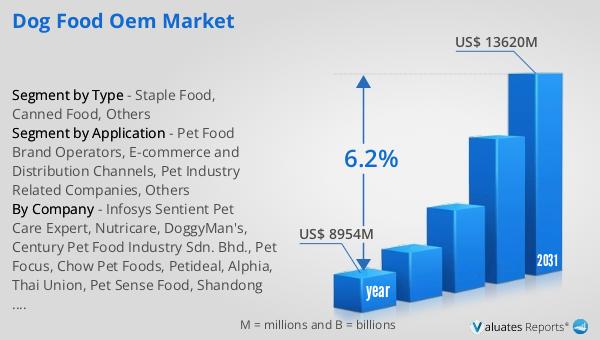

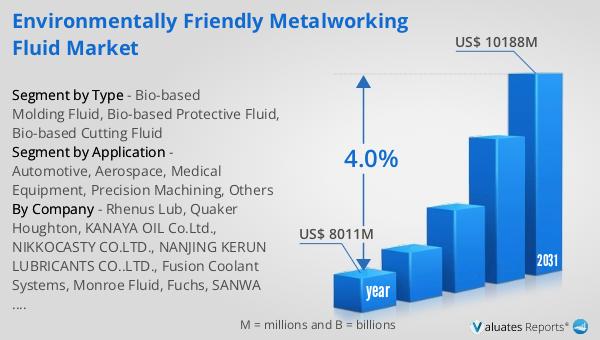

Global Environmentally Friendly Metalworking Fluid Market Outlook:

The global market for Environmentally Friendly Metalworking Fluid was valued at approximately $8,011 million in 2024, and it is anticipated to expand to a revised size of around $10,188 million by 2031. This growth trajectory reflects a compound annual growth rate (CAGR) of 4.0% over the forecast period. This upward trend is indicative of the increasing demand for sustainable and eco-friendly solutions in the metalworking industry. As industries worldwide become more conscious of their environmental impact, the shift towards environmentally friendly metalworking fluids is gaining momentum. These fluids offer a viable alternative to traditional metalworking fluids, which often contain harmful chemicals that can pose significant environmental and health risks. By opting for sustainable options, companies can reduce their ecological footprint, comply with stringent regulations, and enhance their reputation in the market. The projected growth of the market underscores the importance of innovation and investment in the development of high-performance, environmentally friendly metalworking fluids. As the market continues to evolve, businesses that prioritize sustainability and environmental responsibility are likely to gain a competitive edge, attracting environmentally conscious customers and contributing to a more sustainable future.

| Report Metric | Details |

| Report Name | Environmentally Friendly Metalworking Fluid Market |

| Accounted market size in year | US$ 8011 million |

| Forecasted market size in 2031 | US$ 10188 million |

| CAGR | 4.0% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Rhenus Lub, Quaker Houghton, KANAYA OIL Co.Ltd., NIKKOCASTY CO.LTD., NANJING KERUN LUBRICANTS CO..LTD., Fusion Coolant Systems, Monroe Fluid, Fuchs, SANWA CHEMICAL co., ltd., Yushiro Chemical, AMILE Industries, Chemetall, Rowe Oil, ABITEC |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |