What is Global Machine Direction Oriented PE Film Market?

The Global Machine Direction Oriented PE Film Market refers to the worldwide industry focused on the production and distribution of polyethylene films that are oriented in the machine direction. These films are engineered to have enhanced mechanical properties, such as increased tensile strength and improved clarity, by stretching the film in the direction of the machine during the manufacturing process. This orientation process aligns the polymer chains, resulting in films that are thinner yet stronger, making them ideal for various applications. The market encompasses a wide range of industries, including packaging, agriculture, and construction, where these films are used for their durability and cost-effectiveness. The demand for machine direction oriented PE films is driven by the need for sustainable and efficient packaging solutions, as they offer reduced material usage while maintaining performance. Additionally, the market is influenced by technological advancements in film production and the growing emphasis on environmentally friendly materials. As industries continue to seek innovative packaging solutions, the Global Machine Direction Oriented PE Film Market is expected to expand, offering new opportunities for manufacturers and consumers alike.

Blown Films, Cast Films in the Global Machine Direction Oriented PE Film Market:

Blown films and cast films are two primary types of films within the Global Machine Direction Oriented PE Film Market, each with distinct characteristics and applications. Blown films are produced by extruding molten polyethylene through a circular die, forming a tube that is inflated with air to create a bubble. This bubble is then cooled and flattened to form a film. The process of blowing the film allows for the production of films with balanced mechanical properties, such as strength and flexibility, making them suitable for a variety of applications, including packaging, agriculture, and industrial uses. Blown films are known for their versatility and are often used in applications where durability and puncture resistance are essential. On the other hand, cast films are produced by extruding molten polyethylene onto a chilled roller, which rapidly cools the film. This process results in films with excellent clarity and gloss, making them ideal for applications where visual appeal is important, such as food packaging and consumer goods. Cast films are also known for their uniform thickness and superior barrier properties, which help in preserving the freshness and quality of packaged products. In the context of the Global Machine Direction Oriented PE Film Market, both blown and cast films play a crucial role in meeting the diverse needs of various industries. The choice between blown and cast films often depends on the specific requirements of the application, such as the need for strength, clarity, or barrier properties. For instance, in the food packaging industry, cast films are often preferred for their clarity and ability to provide an effective barrier against moisture and oxygen, which helps in extending the shelf life of perishable products. In contrast, blown films are commonly used in agricultural applications, such as greenhouse covers and silage wraps, where strength and durability are paramount. The production of blown and cast films involves different technologies and equipment, each with its own set of advantages and challenges. Blown film production is generally more energy-intensive and requires precise control of the extrusion and cooling processes to achieve the desired film properties. However, it offers greater flexibility in terms of film thickness and width, making it suitable for a wide range of applications. Cast film production, on the other hand, is typically faster and more efficient, with the ability to produce films with consistent thickness and high optical quality. This makes cast films particularly attractive for applications where appearance and performance are critical. As the Global Machine Direction Oriented PE Film Market continues to evolve, manufacturers are investing in advanced technologies and innovations to enhance the performance and sustainability of both blown and cast films. This includes the development of new polymer blends and additives that improve film properties, as well as the adoption of more energy-efficient production processes. Additionally, there is a growing focus on recycling and the use of biodegradable materials to address environmental concerns associated with plastic films. In summary, blown films and cast films are integral components of the Global Machine Direction Oriented PE Film Market, each offering unique benefits and applications. The choice between the two depends on the specific needs of the industry and the desired film properties, with both types playing a vital role in providing effective and sustainable solutions for a wide range of applications.

Food and Beverages, Healthcare and Pharmaceuticals, Personal Care, Other in the Global Machine Direction Oriented PE Film Market:

The Global Machine Direction Oriented PE Film Market finds extensive usage across various sectors, including food and beverages, healthcare and pharmaceuticals, personal care, and other industries. In the food and beverages sector, these films are primarily used for packaging purposes. Their ability to provide a strong barrier against moisture, oxygen, and other environmental factors makes them ideal for preserving the freshness and quality of food products. Machine direction oriented PE films are commonly used in the packaging of snacks, frozen foods, and dairy products, where maintaining product integrity is crucial. The films' clarity and gloss also enhance the visual appeal of packaged goods, making them more attractive to consumers. In the healthcare and pharmaceuticals industry, machine direction oriented PE films are used for packaging medical devices, pharmaceuticals, and other healthcare products. The films' excellent barrier properties help protect sensitive products from contamination and degradation, ensuring their safety and efficacy. Additionally, these films are used in the production of disposable medical supplies, such as surgical drapes and gowns, where their strength and durability are essential. In the personal care sector, machine direction oriented PE films are used in the packaging of cosmetics, toiletries, and other personal care products. The films' ability to provide a strong barrier against moisture and air helps preserve the quality and shelf life of these products. Moreover, the films' clarity and gloss enhance the visual appeal of personal care packaging, making them more attractive to consumers. Beyond these sectors, machine direction oriented PE films are used in various other industries, including agriculture, construction, and electronics. In agriculture, these films are used for applications such as greenhouse covers and silage wraps, where their strength and durability are essential. In the construction industry, machine direction oriented PE films are used as vapor barriers and protective coverings, providing effective solutions for moisture control and insulation. In the electronics industry, these films are used for packaging electronic components, where their excellent barrier properties help protect sensitive components from moisture and static electricity. Overall, the Global Machine Direction Oriented PE Film Market plays a vital role in providing effective and sustainable packaging solutions across a wide range of industries. The films' unique properties, such as strength, clarity, and barrier performance, make them ideal for various applications, helping industries meet their packaging needs while addressing environmental concerns.

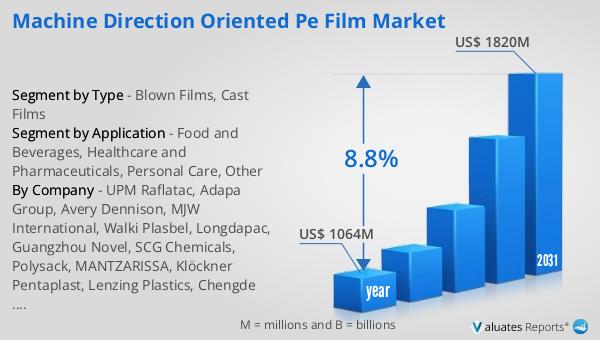

Global Machine Direction Oriented PE Film Market Outlook:

The worldwide market for Machine Direction Oriented PE Film was appraised at $1,064 million in 2024 and is anticipated to expand to a revised valuation of $1,820 million by 2031, reflecting a compound annual growth rate (CAGR) of 8.8% over the forecast period. This growth trajectory underscores the increasing demand for these films across various industries due to their enhanced mechanical properties and cost-effectiveness. The market's expansion is driven by the rising need for sustainable packaging solutions that offer reduced material usage without compromising performance. As industries continue to prioritize environmentally friendly materials, the demand for machine direction oriented PE films is expected to grow. The market's growth is also supported by technological advancements in film production, which have led to the development of films with improved strength, clarity, and barrier properties. These advancements have expanded the range of applications for machine direction oriented PE films, further fueling market growth. Additionally, the increasing emphasis on reducing plastic waste and promoting recycling has led to the adoption of more sustainable production processes and materials, contributing to the market's positive outlook. As the market continues to evolve, manufacturers are likely to focus on innovation and sustainability to meet the growing demand for machine direction oriented PE films across various sectors.

| Report Metric | Details |

| Report Name | Machine Direction Oriented PE Film Market |

| Accounted market size in year | US$ 1064 million |

| Forecasted market size in 2031 | US$ 1820 million |

| CAGR | 8.8% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | UPM Raflatac, Adapa Group, Avery Dennison, MJW International, Walki Plasbel, Longdapac, Guangzhou Novel, SCG Chemicals, Polysack, MANTZARISSA, Klöckner Pentaplast, Lenzing Plastics, Chengde Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |