What is Global Solid State Laser Lift Off Equipment Market?

The Global Solid State Laser Lift Off Equipment Market is a specialized segment within the broader laser technology industry. This market focuses on equipment that utilizes solid-state lasers to perform the lift-off process, which is crucial in various manufacturing applications. Solid-state lasers are known for their efficiency, precision, and reliability, making them ideal for delicate processes that require high accuracy. The lift-off process involves separating layers of materials without causing damage to the underlying substrate, which is essential in industries like electronics and semiconductors. The demand for such equipment is driven by the increasing need for advanced manufacturing techniques that can enhance product quality and reduce production costs. As industries continue to innovate and develop new technologies, the role of solid-state laser lift-off equipment becomes increasingly significant. This market is characterized by continuous advancements in laser technology, which aim to improve the efficiency and effectiveness of the lift-off process. Companies operating in this market are focused on research and development to create more advanced and versatile equipment that can cater to a wide range of applications. The growth of this market is also supported by the rising adoption of laser technology in various industrial sectors, highlighting its importance in modern manufacturing processes.

Fully-automatic, Semi-automatic in the Global Solid State Laser Lift Off Equipment Market:

In the Global Solid State Laser Lift Off Equipment Market, equipment can be categorized based on their level of automation: fully-automatic and semi-automatic systems. Fully-automatic systems are designed to perform the lift-off process with minimal human intervention. These systems are equipped with advanced sensors and software that allow them to operate independently, ensuring high precision and consistency in the manufacturing process. The primary advantage of fully-automatic systems is their ability to handle large volumes of work efficiently, making them ideal for mass production environments. They are often used in industries where speed and accuracy are critical, such as in the production of electronic components and semiconductors. On the other hand, semi-automatic systems require some level of human involvement to operate. While they still utilize advanced laser technology to perform the lift-off process, operators are needed to oversee the process and make adjustments as necessary. Semi-automatic systems offer more flexibility compared to their fully-automatic counterparts, as they allow for greater control over the manufacturing process. This makes them suitable for applications where customization and adaptability are important. For instance, in research and development settings, semi-automatic systems can be used to experiment with different materials and processes, providing valuable insights that can lead to innovation. Both fully-automatic and semi-automatic systems have their own set of advantages and are chosen based on the specific needs of the application. The choice between the two often depends on factors such as production volume, budget, and the level of precision required. As technology continues to evolve, the distinction between fully-automatic and semi-automatic systems may become less pronounced, with hybrid systems that combine the best features of both becoming more prevalent. These hybrid systems could offer the efficiency of fully-automatic systems with the flexibility of semi-automatic systems, providing a comprehensive solution for various manufacturing challenges. The development of such systems would require ongoing research and collaboration between industry experts and technology developers to ensure that they meet the ever-changing demands of the market. As the Global Solid State Laser Lift Off Equipment Market continues to grow, the focus on automation and efficiency will remain a key driver of innovation and development.

OLED, Others in the Global Solid State Laser Lift Off Equipment Market:

The Global Solid State Laser Lift Off Equipment Market finds significant usage in the production of OLEDs (Organic Light Emitting Diodes) and other applications. OLED technology is widely used in the display industry, particularly for screens in smartphones, televisions, and other electronic devices. The lift-off process is crucial in the manufacturing of OLEDs, as it allows for the precise removal of layers without damaging the delicate organic materials involved. Solid-state laser lift-off equipment provides the precision and control needed to ensure high-quality OLED displays, which are known for their vibrant colors and energy efficiency. The use of this equipment in OLED production helps manufacturers achieve the desired thinness and flexibility of the displays, which are key selling points in the consumer electronics market. Beyond OLEDs, solid-state laser lift-off equipment is also used in other applications that require precise material removal. This includes the production of microelectromechanical systems (MEMS), which are used in a variety of industries, including automotive, healthcare, and telecommunications. In these applications, the lift-off process is used to create intricate patterns and structures on a microscopic scale, which are essential for the functionality of MEMS devices. The versatility of solid-state laser lift-off equipment makes it a valuable tool in the development of advanced technologies across different sectors. As industries continue to push the boundaries of innovation, the demand for precise and efficient manufacturing processes will only increase. The Global Solid State Laser Lift Off Equipment Market is well-positioned to meet this demand, providing the tools necessary for the production of cutting-edge technologies. The ongoing advancements in laser technology will further enhance the capabilities of lift-off equipment, enabling manufacturers to achieve even greater levels of precision and efficiency. This will not only benefit the industries currently using this technology but also open up new possibilities for its application in other areas. As a result, the Global Solid State Laser Lift Off Equipment Market is expected to play a crucial role in the future of manufacturing, driving innovation and growth across various sectors.

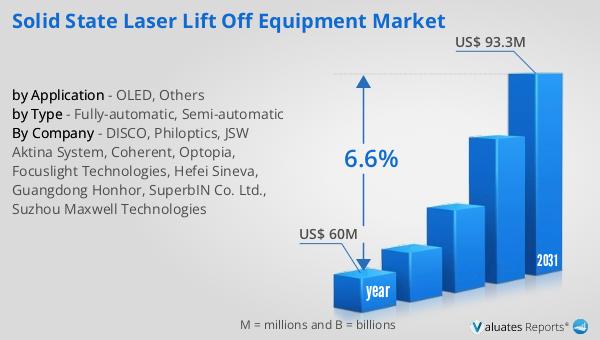

Global Solid State Laser Lift Off Equipment Market Outlook:

The outlook for the Global Solid State Laser Lift Off Equipment Market indicates a promising growth trajectory. In 2024, the market was valued at approximately US$ 60 million, and it is anticipated to expand to a revised size of US$ 93.3 million by 2031. This growth represents a compound annual growth rate (CAGR) of 6.6% over the forecast period. Such a robust growth rate underscores the increasing demand for solid-state laser lift-off equipment across various industries. The market's expansion can be attributed to several factors, including the rising adoption of advanced manufacturing techniques and the growing need for precision in production processes. As industries continue to evolve and innovate, the demand for equipment that can deliver high accuracy and efficiency is expected to rise. The solid-state laser lift-off equipment market is well-positioned to capitalize on these trends, offering solutions that meet the needs of modern manufacturing. The projected growth also highlights the importance of ongoing research and development in this field, as companies strive to enhance the capabilities of their equipment and stay ahead of the competition. As the market continues to grow, it will likely attract new players and investments, further driving innovation and development in the industry. This positive outlook reflects the critical role that solid-state laser lift-off equipment plays in the advancement of technology and manufacturing processes.

| Report Metric | Details |

| Report Name | Solid State Laser Lift Off Equipment Market |

| Accounted market size in year | US$ 60 million |

| Forecasted market size in 2031 | US$ 93.3 million |

| CAGR | 6.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | DISCO, Philoptics, JSW Aktina System, Coherent, Optopia, Focuslight Technologies, Hefei Sineva, Guangdong Honhor, SuperbIN Co. Ltd., Suzhou Maxwell Technologies |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |