What is Global Specialty Gas for Display Market?

Global Specialty Gas for Display Market refers to a niche segment within the broader specialty gas industry, focusing specifically on gases used in the production and functioning of display technologies. These gases are crucial in manufacturing processes for various display types, including LCDs, OLEDs, and LEDs. Specialty gases are high-purity gases that serve specific functions in the production process, such as acting as reactants, etchants, or protective atmospheres. The demand for these gases is driven by the growing consumer electronics market, which includes televisions, smartphones, tablets, and other devices that utilize advanced display technologies. As display technologies evolve, the need for precise and high-quality specialty gases becomes even more critical to ensure optimal performance and efficiency. The market is characterized by continuous innovation and development, as manufacturers strive to improve display quality, reduce production costs, and enhance energy efficiency. This market is also influenced by environmental regulations and the push for sustainable manufacturing practices, which can impact the types of gases used and the methods of their application. Overall, the Global Specialty Gas for Display Market is a dynamic and essential component of the electronics manufacturing industry, playing a pivotal role in the advancement of display technologies.

CVD Gas, Deposition Gas, Ion Implantation Gas, Etching Gas, Laser Gas in the Global Specialty Gas for Display Market:

In the Global Specialty Gas for Display Market, several types of gases play crucial roles in the manufacturing processes of display technologies. CVD Gas, or Chemical Vapor Deposition Gas, is used in the deposition of thin films on substrates, a fundamental step in creating display panels. This process involves the chemical reaction of gaseous precursors, which decompose on the substrate surface to form a solid film. CVD gases are essential for ensuring uniformity and quality in the thin films, which directly impact the display's performance and longevity. Deposition Gas, similar to CVD Gas, is used in various deposition techniques, including physical vapor deposition (PVD) and atomic layer deposition (ALD). These gases help in forming layers of materials on substrates, crucial for the construction of display components. Ion Implantation Gas is another critical type, used in the doping process to modify the electrical properties of semiconductor materials. This process involves bombarding the substrate with ions, which are introduced using gases like phosphine or arsine. The precise control of ion implantation is vital for the functionality of semiconductor devices used in displays. Etching Gas is used in the etching process, where specific areas of a material are removed to create patterns or structures. This process is essential for defining the intricate circuits and components within a display. Common etching gases include fluorine-based compounds, which provide the necessary reactivity to etch materials like silicon or glass. Laser Gas is used in laser-based processes, such as laser cutting or laser annealing, which are employed in the manufacturing of displays. These gases, often mixtures of carbon dioxide, nitrogen, and helium, are used to generate the laser beam required for precise material processing. Each of these gases plays a unique and indispensable role in the production of display technologies, contributing to the overall efficiency, quality, and performance of the final product. The choice and application of these gases are critical, as they directly influence the manufacturing process's cost-effectiveness and environmental impact. As the demand for high-quality displays continues to grow, the importance of these specialty gases in the display market cannot be overstated.

LCD, OLED, LED in the Global Specialty Gas for Display Market:

The usage of Global Specialty Gas for Display Market in LCD, OLED, and LED technologies is integral to their manufacturing processes. In Liquid Crystal Displays (LCDs), specialty gases are used in various stages, including the deposition of thin films and the etching of circuits. CVD gases are employed to create the thin film transistors (TFTs) that control the pixels in an LCD. These gases ensure the uniformity and quality of the films, which are crucial for the display's clarity and color accuracy. Etching gases are used to define the intricate patterns of the circuits, ensuring precise control over the electrical pathways. In Organic Light Emitting Diodes (OLEDs), specialty gases play a vital role in the deposition of organic layers that emit light. The use of high-purity deposition gases ensures the formation of uniform and defect-free layers, which are essential for the display's brightness and efficiency. OLEDs also benefit from the use of laser gases in processes like laser annealing, which improves the performance of the organic materials. In Light Emitting Diodes (LEDs), specialty gases are used in the epitaxial growth of semiconductor layers, a critical step in LED manufacturing. CVD gases are used to deposit these layers, ensuring the precise composition and thickness required for optimal light emission. Ion implantation gases are also used to modify the electrical properties of the semiconductor materials, enhancing the LED's performance. The use of specialty gases in these display technologies is not only crucial for their manufacturing but also for their ongoing development and improvement. As the demand for higher resolution, better color accuracy, and energy efficiency in displays continues to rise, the role of specialty gases in achieving these goals becomes increasingly important. The careful selection and application of these gases are essential for meeting the stringent quality and performance standards required in the competitive display market.

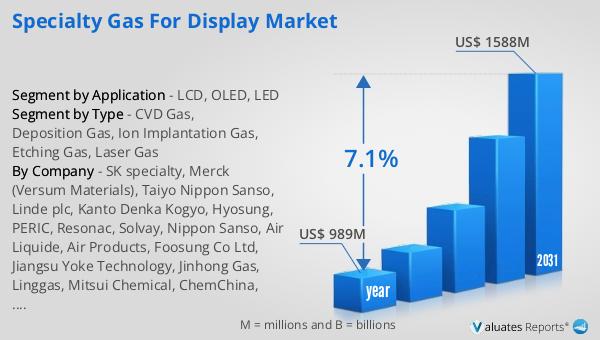

Global Specialty Gas for Display Market Outlook:

The global market for Specialty Gas for Display was valued at approximately $989 million in 2024. It is anticipated to grow significantly, reaching an estimated size of $1,588 million by 2031. This growth trajectory represents a compound annual growth rate (CAGR) of 7.1% over the forecast period. This expansion is driven by the increasing demand for advanced display technologies across various consumer electronics, including smartphones, televisions, and tablets. As these devices become more sophisticated, the need for high-quality specialty gases in their production processes becomes more critical. The market's growth is also supported by ongoing innovations in display technology, which require precise and high-purity gases to achieve the desired performance and efficiency. Additionally, environmental regulations and the push for sustainable manufacturing practices are influencing the types of gases used and their application methods. This market outlook highlights the dynamic nature of the Global Specialty Gas for Display Market and its essential role in the electronics manufacturing industry. The projected growth underscores the importance of these gases in the continued advancement of display technologies, as manufacturers strive to meet the evolving demands of consumers and regulatory bodies.

| Report Metric | Details |

| Report Name | Specialty Gas for Display Market |

| Accounted market size in year | US$ 989 million |

| Forecasted market size in 2031 | US$ 1588 million |

| CAGR | 7.1% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| Segment by Type |

|

| Segment by Application |

|

| By Region |

|

| By Company | SK specialty, Merck (Versum Materials), Taiyo Nippon Sanso, Linde plc, Kanto Denka Kogyo, Hyosung, PERIC, Resonac, Solvay, Nippon Sanso, Air Liquide, Air Products, Foosung Co Ltd, Jiangsu Yoke Technology, Jinhong Gas, Linggas, Mitsui Chemical, ChemChina, Shandong FeiYuan, Guangdong Huate Gas, Central Glass, Jiangsu Nata Opto-electronic Material, Hunan Kaimeite Gases |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |