What is Global Laser Bonder Market?

The Global Laser Bonder Market is a specialized segment within the semiconductor and electronics manufacturing industry. Laser bonders are advanced machines used to precisely join materials using laser technology, which is crucial in the production of microelectronics. These machines are essential for creating strong, reliable connections in semiconductor devices, which are used in a wide range of applications from consumer electronics to automotive systems. The market for laser bonders is driven by the increasing demand for miniaturized electronic components and the need for high precision in manufacturing processes. As technology advances, the need for efficient and accurate bonding solutions grows, making laser bonders an integral part of modern manufacturing. The market is characterized by continuous innovation, with manufacturers focusing on improving the speed, accuracy, and versatility of laser bonding equipment to meet the evolving needs of the industry. This market is also influenced by the trends in semiconductor manufacturing, such as the shift towards smaller, more powerful devices, which require advanced bonding techniques. Overall, the Global Laser Bonder Market plays a critical role in the advancement of technology and the production of high-performance electronic devices.

Fully-automatic, Semi-automatic in the Global Laser Bonder Market:

In the Global Laser Bonder Market, equipment can be categorized into fully-automatic and semi-automatic systems, each serving distinct needs within the manufacturing process. Fully-automatic laser bonders are designed for high-volume production environments where speed and precision are paramount. These machines are equipped with advanced software and robotics that allow them to operate with minimal human intervention, ensuring consistent quality and efficiency. They are ideal for large-scale manufacturing facilities that produce a high volume of semiconductor devices, as they can significantly reduce labor costs and increase throughput. The automation in these systems allows for precise control over the bonding process, which is crucial for maintaining the integrity of delicate electronic components. On the other hand, semi-automatic laser bonders offer a balance between automation and manual control. These systems are typically used in smaller production runs or in environments where flexibility is required. Semi-automatic bonders allow operators to have more control over the bonding process, which can be beneficial for complex or custom applications where specific adjustments are needed. They are often used in research and development settings or in the production of specialized components where precision and customization are more important than speed. Both types of laser bonders are essential in the semiconductor industry, as they provide the necessary tools to create reliable and high-quality connections in electronic devices. The choice between fully-automatic and semi-automatic systems depends on the specific needs of the manufacturer, including production volume, complexity of the components, and budget considerations. As the demand for advanced electronic devices continues to grow, the Global Laser Bonder Market is expected to see increased adoption of both fully-automatic and semi-automatic systems, each playing a crucial role in the advancement of semiconductor manufacturing.

Chip Scale Packaging, Flip Chip Packaging, Wafer Level Packaging, Others in the Global Laser Bonder Market:

The Global Laser Bonder Market finds significant applications in various packaging technologies, including Chip Scale Packaging (CSP), Flip Chip Packaging, Wafer Level Packaging (WLP), and others. In Chip Scale Packaging, laser bonders are used to create precise connections between the chip and the substrate, ensuring reliable performance and miniaturization of electronic devices. CSP is a popular choice in consumer electronics due to its compact size and cost-effectiveness, and laser bonders play a crucial role in achieving the high precision required for these applications. In Flip Chip Packaging, laser bonders are used to attach the chip directly to the substrate, eliminating the need for wire bonds and allowing for higher performance and efficiency. This packaging method is commonly used in high-performance applications such as processors and graphic chips, where speed and reliability are critical. Laser bonders provide the precision and control needed to create strong, reliable connections in these demanding applications. Wafer Level Packaging is another area where laser bonders are extensively used. This packaging method involves packaging the entire wafer before it is diced into individual chips, allowing for greater efficiency and cost savings. Laser bonders are used to create the necessary connections between the wafer and the packaging materials, ensuring the integrity and performance of the final product. Other applications of laser bonders in the Global Laser Bonder Market include the production of sensors, LEDs, and other electronic components where precision and reliability are essential. The versatility and precision of laser bonders make them an indispensable tool in the production of advanced electronic devices, and their use is expected to grow as the demand for miniaturized and high-performance components continues to increase.

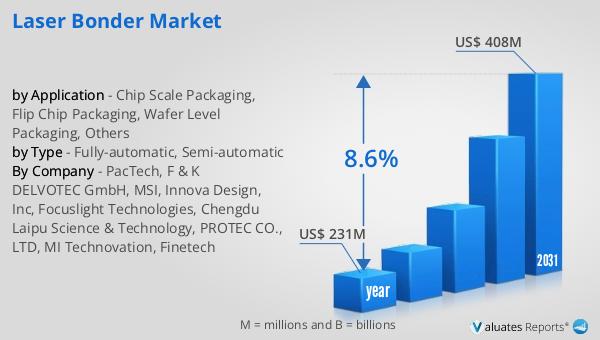

Global Laser Bonder Market Outlook:

In 2024, the global market for Laser Bonder was valued at approximately $231 million. This market is anticipated to expand significantly, reaching an estimated size of $408 million by 2031. This growth is projected to occur at a compound annual growth rate (CAGR) of 8.6% over the forecast period. The increasing demand for advanced electronic devices and the need for precise and efficient manufacturing processes are key drivers of this growth. As technology continues to evolve, the demand for miniaturized and high-performance components is expected to rise, further fueling the growth of the Laser Bonder Market. The market's expansion is also supported by the continuous innovation in laser bonding technology, which is aimed at improving the speed, accuracy, and versatility of these machines. Manufacturers are investing in research and development to create more advanced laser bonders that can meet the evolving needs of the semiconductor industry. The growing adoption of laser bonders in various applications, including Chip Scale Packaging, Flip Chip Packaging, and Wafer Level Packaging, is also contributing to the market's growth. As the demand for reliable and high-quality electronic devices continues to increase, the Global Laser Bonder Market is expected to play a crucial role in the advancement of semiconductor manufacturing.

| Report Metric | Details |

| Report Name | Laser Bonder Market |

| Accounted market size in year | US$ 231 million |

| Forecasted market size in 2031 | US$ 408 million |

| CAGR | 8.6% |

| Base Year | year |

| Forecasted years | 2025 - 2031 |

| by Type |

|

| by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | PacTech, F & K DELVOTEC GmbH, MSI, Innova Design, Inc, Focuslight Technologies, Chengdu Laipu Science & Technology, PROTEC CO., LTD, MI Technovation, Finetech |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |