What is Global Suction Tube with Bone Filter Market?

The Global Suction Tube with Bone Filter Market refers to the industry that produces and sells specialized medical devices used primarily in surgical procedures. These suction tubes are equipped with bone filters to ensure that bone fragments and other debris are effectively removed from the surgical site, thereby maintaining a clear field of vision for the surgeon. This technology is crucial in various types of surgeries, including orthopedic, dental, and maxillofacial procedures. The market for these devices is expanding due to the increasing number of surgical procedures worldwide, advancements in medical technology, and a growing awareness of the importance of maintaining a sterile surgical environment. The demand is also driven by the rising prevalence of chronic diseases that require surgical intervention, such as osteoporosis and dental conditions. The market is characterized by a range of products that vary in terms of design, material, and functionality, catering to the diverse needs of healthcare professionals.

Disposable, Reusable in the Global Suction Tube with Bone Filter Market:

In the Global Suction Tube with Bone Filter Market, products can be broadly categorized into disposable and reusable types. Disposable suction tubes with bone filters are designed for single-use applications. They are typically made from medical-grade plastics and are pre-sterilized, ensuring that they are free from contaminants when used in surgical procedures. The primary advantage of disposable suction tubes is that they eliminate the risk of cross-contamination between patients, which is a significant concern in healthcare settings. These tubes are particularly popular in high-volume surgical centers and hospitals where the turnover of patients is rapid, and the need for quick, efficient, and safe surgical tools is paramount. On the other hand, reusable suction tubes with bone filters are made from more durable materials such as stainless steel or high-grade polymers that can withstand repeated sterilization processes. These tubes are designed to be used multiple times, making them a cost-effective option for healthcare facilities that perform a high number of surgeries. Reusable tubes require rigorous cleaning and sterilization between uses to ensure they remain safe and effective. The choice between disposable and reusable suction tubes often depends on various factors, including the type of surgical procedure, the healthcare facility's budget, and the preference of the surgical team. Both types of suction tubes play a crucial role in maintaining a clear surgical field, thereby enhancing the precision and safety of surgical procedures.

Dental Clinics, Dental Hospitals in the Global Suction Tube with Bone Filter Market:

The Global Suction Tube with Bone Filter Market finds significant usage in dental clinics and dental hospitals. In dental clinics, these devices are essential for procedures that involve bone cutting or drilling, such as dental implant surgeries, tooth extractions, and bone grafting. The suction tube with a bone filter helps in efficiently removing bone fragments and other debris from the surgical site, ensuring that the dentist has a clear view of the area being treated. This not only enhances the precision of the procedure but also reduces the risk of complications such as infections. Dental clinics, which often handle a high volume of patients, benefit from the use of disposable suction tubes as they help in maintaining a sterile environment and prevent cross-contamination. In dental hospitals, where more complex and extensive dental surgeries are performed, both disposable and reusable suction tubes are used. Reusable suction tubes are particularly favored in these settings due to their cost-effectiveness and durability. Dental hospitals often have the necessary infrastructure to sterilize and maintain reusable surgical instruments, making them a practical choice. The use of suction tubes with bone filters in dental hospitals is crucial for procedures such as orthognathic surgeries, maxillofacial surgeries, and other advanced dental treatments. These devices play a vital role in ensuring the success of the surgery by providing a clear surgical field and minimizing the risk of post-operative complications. Overall, the use of suction tubes with bone filters in dental clinics and dental hospitals is integral to the delivery of high-quality dental care.

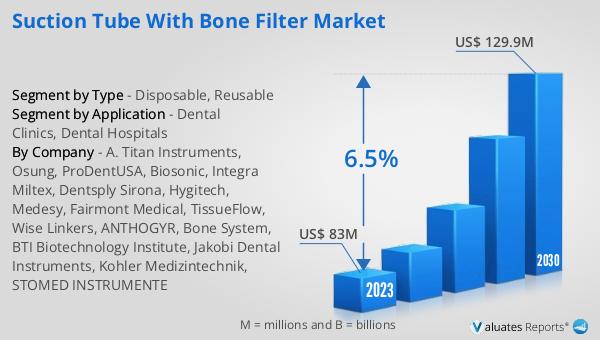

Global Suction Tube with Bone Filter Market Outlook:

The global market for Suction Tubes with Bone Filters was valued at approximately USD 83 million in 2023. Projections indicate that this market is expected to grow significantly, reaching around USD 129.9 million by the year 2030. This growth is anticipated to occur at a compound annual growth rate (CAGR) of 6.5% during the forecast period from 2024 to 2030. This upward trend can be attributed to several factors, including the increasing number of surgical procedures worldwide, advancements in medical technology, and a growing awareness of the importance of maintaining a sterile surgical environment. The rising prevalence of chronic diseases that require surgical intervention, such as osteoporosis and dental conditions, also contributes to the expanding market. The market is characterized by a range of products that vary in terms of design, material, and functionality, catering to the diverse needs of healthcare professionals. The demand for these devices is expected to continue growing as healthcare providers seek to improve surgical outcomes and patient safety.

| Report Metric | Details |

| Report Name | Suction Tube with Bone Filter Market |

| Accounted market size in 2023 | US$ 83 million |

| Forecasted market size in 2030 | US$ 129.9 million |

| CAGR | 6.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Consumption by Region |

|

| By Company | A. Titan Instruments, Osung, ProDentUSA, Biosonic, Integra Miltex, Dentsply Sirona, Hygitech, Medesy, Fairmont Medical, TissueFlow, Wise Linkers, ANTHOGYR, Bone System, BTI Biotechnology Institute, Jakobi Dental Instruments, Kohler Medizintechnik, STOMED INSTRUMENTE |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |