What is Dual Arm CMM - Global Market?

Dual Arm Coordinate Measuring Machines (CMMs) are advanced tools used in the global market for precise measurement and inspection tasks. These machines are equipped with two arms, allowing them to perform simultaneous measurements, which significantly enhances their efficiency and accuracy. The dual-arm design is particularly beneficial in complex manufacturing environments where speed and precision are critical. These machines are widely used in industries such as automotive, aerospace, and heavy machinery, where they help ensure that components meet stringent quality standards. The global market for Dual Arm CMMs is driven by the increasing demand for high-precision measurement tools in manufacturing processes. As industries continue to evolve and adopt more advanced technologies, the need for accurate and reliable measurement solutions like Dual Arm CMMs is expected to grow. This growth is further supported by technological advancements that have made these machines more accessible and easier to integrate into existing production lines. Overall, the Dual Arm CMM market is poised for significant expansion as industries worldwide recognize the value of precision measurement in maintaining competitive advantage and ensuring product quality.

Tactile or Contact CMM, Optical CMM, Other in the Dual Arm CMM - Global Market:

Tactile or Contact CMMs, Optical CMMs, and other types of CMMs each play a distinct role in the Dual Arm CMM global market. Tactile or Contact CMMs are traditional machines that use a probe to physically touch the part being measured. This method is highly accurate and is often used in applications where precision is paramount. The tactile approach is ideal for measuring complex geometries and ensuring that parts meet exact specifications. However, it can be time-consuming, especially for large or intricate components. On the other hand, Optical CMMs use cameras and lasers to capture measurements without physical contact. This non-contact method is faster and can be used on delicate or soft materials that might be damaged by a tactile probe. Optical CMMs are particularly useful in industries where speed and non-destructive testing are critical, such as electronics and medical devices. Other types of CMMs in the market include hybrid models that combine both tactile and optical technologies, offering the best of both worlds. These machines provide flexibility and can be tailored to specific measurement needs, making them a popular choice in diverse industries. The global market for Dual Arm CMMs is influenced by the unique advantages and limitations of each type of CMM. As technology continues to advance, the capabilities of these machines are expected to expand, further driving their adoption across various sectors. The choice between tactile, optical, and other CMMs often depends on the specific requirements of the application, such as the level of precision needed, the material being measured, and the speed of measurement. As industries strive for greater efficiency and accuracy, the demand for advanced CMM solutions is likely to increase, supporting the growth of the Dual Arm CMM market.

Automotive, Aerospace, Heavy Machinery, Others in the Dual Arm CMM - Global Market:

The usage of Dual Arm CMMs in the automotive industry is primarily focused on ensuring the precision and quality of components. These machines are used to measure complex parts such as engine blocks, transmission systems, and body panels, ensuring they meet strict tolerances. The ability to perform simultaneous measurements with dual arms enhances productivity and reduces inspection times, which is crucial in the fast-paced automotive sector. In the aerospace industry, Dual Arm CMMs are employed to inspect critical components like turbine blades, fuselage sections, and landing gear. The high precision offered by these machines is essential for maintaining safety and performance standards in aerospace applications. The dual-arm capability allows for the efficient measurement of large and complex parts, which is a significant advantage in this industry. In the heavy machinery sector, Dual Arm CMMs are used to measure large components such as gears, shafts, and frames. The robust design of these machines makes them suitable for the demanding environments often found in heavy machinery manufacturing. The ability to handle large parts with precision ensures that machinery operates efficiently and reliably. Beyond these industries, Dual Arm CMMs find applications in various other sectors, including electronics, medical devices, and consumer goods. In electronics, they are used to measure intricate circuit boards and components, ensuring they meet design specifications. In the medical field, Dual Arm CMMs help in the precise measurement of prosthetics and implants, contributing to better patient outcomes. The versatility and precision of Dual Arm CMMs make them valuable tools across a wide range of industries, supporting quality assurance and innovation.

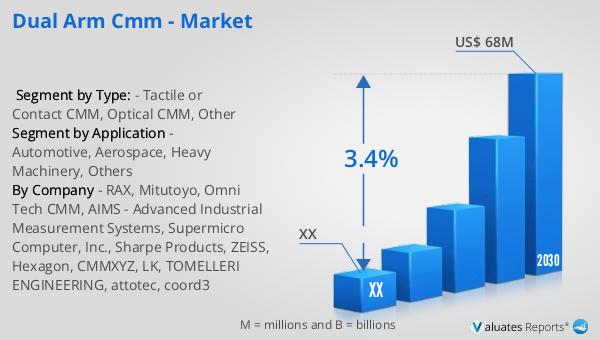

Dual Arm CMM - Global Market Outlook:

The global market for Dual Arm CMMs was valued at approximately $35 million in 2023. It is projected to grow to a revised size of $68 million by 2030, reflecting a compound annual growth rate (CAGR) of 3.4% during the forecast period from 2024 to 2030. This growth is indicative of the increasing demand for precision measurement tools across various industries. In North America, the market for Dual Arm CMMs was valued at a certain amount in 2023 and is expected to reach a specific value by 2030, with a CAGR of a certain percentage during the forecast period. This regional growth highlights the importance of Dual Arm CMMs in maintaining competitive advantage and ensuring product quality in North American industries. The market outlook suggests that as industries continue to evolve and adopt more advanced technologies, the need for accurate and reliable measurement solutions like Dual Arm CMMs will continue to grow. This growth is further supported by technological advancements that have made these machines more accessible and easier to integrate into existing production lines. Overall, the Dual Arm CMM market is poised for significant expansion as industries worldwide recognize the value of precision measurement in maintaining competitive advantage and ensuring product quality.

| Report Metric | Details |

| Report Name | Dual Arm CMM - Market |

| Forecasted market size in 2030 | US$ 68 million |

| CAGR | 3.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | RAX, Mitutoyo, Omni Tech CMM, AIMS - Advanced Industrial Measurement Systems, Supermicro Computer, Inc., Sharpe Products, ZEISS, Hexagon, CMMXYZ, LK, TOMELLERI ENGINEERING, attotec, coord3 |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |