What is VCI Foam - Global Market?

VCI Foam, or Volatile Corrosion Inhibitor Foam, is a specialized material used globally to protect metal surfaces from corrosion. This foam is impregnated with chemical compounds that release corrosion-inhibiting vapors. These vapors form a protective layer on metal surfaces, preventing moisture and other corrosive elements from causing damage. The global market for VCI Foam is driven by its effectiveness in safeguarding metal products during storage and transportation. Industries such as automotive, electronics, aerospace, and metal manufacturing rely heavily on VCI Foam to ensure the longevity and integrity of their products. The demand for VCI Foam is increasing as industries seek more efficient and reliable methods to protect their metal components from corrosion. This market is characterized by continuous innovation, with manufacturers developing new formulations to enhance the protective capabilities of VCI Foam. As industries continue to expand globally, the need for effective corrosion protection solutions like VCI Foam is expected to grow, making it a crucial component in the global market for corrosion prevention materials.

Nitrite-free, Other in the VCI Foam - Global Market:

Nitrite-free VCI Foam represents a significant advancement in the global market for corrosion protection materials. Traditional VCI Foams often contain nitrites, which, while effective at inhibiting corrosion, pose environmental and health concerns. Nitrite-free VCI Foam addresses these issues by using alternative compounds that are safer for both the environment and human health. This innovation is particularly important as industries worldwide face increasing pressure to adopt more sustainable and eco-friendly practices. The development of nitrite-free VCI Foam involves extensive research and testing to ensure that the alternative compounds used are as effective as traditional nitrites in preventing corrosion. Manufacturers are investing in advanced technologies and materials science to create VCI Foams that not only meet but exceed the performance of their nitrite-containing counterparts. The transition to nitrite-free VCI Foam is also driven by regulatory changes in many countries, which are imposing stricter limits on the use of hazardous substances in industrial products. As a result, companies are increasingly adopting nitrite-free VCI Foam to comply with these regulations and to demonstrate their commitment to sustainability. The benefits of nitrite-free VCI Foam extend beyond environmental considerations. These foams are also designed to offer superior protection against a wide range of corrosive elements, including moisture, salt, and industrial pollutants. This makes them suitable for use in diverse environments and industries, from automotive manufacturing to electronics production. The versatility of nitrite-free VCI Foam is a key factor in its growing popularity. It can be used to protect a variety of metal surfaces, including steel, aluminum, and copper, making it an ideal solution for companies with diverse product lines. Additionally, nitrite-free VCI Foam is available in various forms, such as sheets, rolls, and custom shapes, allowing for easy integration into existing packaging and storage systems. The global market for nitrite-free VCI Foam is also benefiting from increased awareness among consumers and businesses about the importance of corrosion protection. As more companies recognize the cost savings and operational efficiencies that can be achieved by preventing corrosion, the demand for effective solutions like nitrite-free VCI Foam is expected to rise. This trend is further supported by advancements in digital technologies, which are enabling companies to monitor and manage corrosion risks more effectively. By using data analytics and IoT devices, businesses can gain real-time insights into the condition of their metal assets and take proactive measures to prevent corrosion. This proactive approach is driving the adoption of nitrite-free VCI Foam as part of comprehensive corrosion management strategies. In conclusion, nitrite-free VCI Foam is poised to play a pivotal role in the global market for corrosion protection materials. Its environmental benefits, combined with its effectiveness and versatility, make it an attractive option for industries seeking to enhance their corrosion prevention efforts. As regulatory pressures and consumer expectations continue to evolve, the demand for nitrite-free VCI Foam is likely to grow, solidifying its position as a key component in the fight against corrosion.

Automotive, Electronics, Aerospace, Metal in the VCI Foam - Global Market:

VCI Foam is widely used in various industries, including automotive, electronics, aerospace, and metal manufacturing, due to its exceptional corrosion protection properties. In the automotive industry, VCI Foam is crucial for protecting metal parts and components during storage and transportation. Car manufacturers and suppliers use VCI Foam to prevent rust and corrosion on parts such as engines, transmissions, and body panels. This ensures that the components remain in optimal condition until they are assembled into vehicles. The use of VCI Foam in the automotive sector helps reduce maintenance costs and extends the lifespan of metal parts, contributing to overall vehicle quality and reliability. In the electronics industry, VCI Foam is used to protect sensitive electronic components and devices from corrosion. Electronic devices often contain metal parts that are susceptible to corrosion, which can lead to malfunctions and failures. VCI Foam provides a protective barrier that prevents moisture and other corrosive elements from damaging these components. This is particularly important for manufacturers of consumer electronics, such as smartphones, laptops, and tablets, where product reliability is paramount. By using VCI Foam, electronics manufacturers can ensure that their products meet high-quality standards and maintain their functionality over time. The aerospace industry also relies on VCI Foam to protect metal parts and equipment from corrosion. Aircraft components, such as engines, landing gear, and structural parts, are exposed to harsh environmental conditions that can accelerate corrosion. VCI Foam helps mitigate these risks by providing a protective layer that shields metal surfaces from moisture, salt, and other corrosive agents. This is essential for maintaining the safety and performance of aircraft, as well as reducing maintenance costs and downtime. In the metal manufacturing industry, VCI Foam is used to protect raw materials and finished products from corrosion during storage and transportation. Metal manufacturers produce a wide range of products, from steel beams to aluminum sheets, which are often stored for extended periods before being used or sold. VCI Foam helps preserve the quality and integrity of these products by preventing corrosion, ensuring that they remain in pristine condition until they reach their final destination. This is particularly important for manufacturers that export their products to international markets, where long shipping times can increase the risk of corrosion. Overall, the use of VCI Foam in these industries highlights its versatility and effectiveness as a corrosion protection solution. By preventing corrosion, VCI Foam helps companies reduce costs, improve product quality, and enhance customer satisfaction. As industries continue to evolve and face new challenges, the demand for reliable and efficient corrosion protection solutions like VCI Foam is expected to grow, further solidifying its role in the global market.

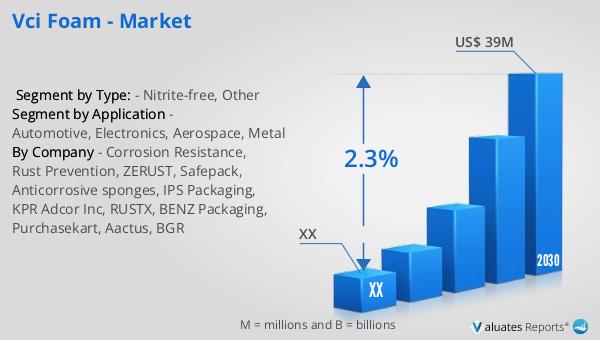

VCI Foam - Global Market Outlook:

In 2023, the global market for VCI Foam was valued at approximately $32 million. Looking ahead, it is projected to reach an adjusted value of $39 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.3% during the forecast period from 2024 to 2030. This growth indicates a steady increase in demand for VCI Foam as industries continue to prioritize corrosion protection for their metal products. The North American market for VCI Foam also shows promising growth prospects. Although specific figures for the North American market in 2023 and 2030 are not provided, it is expected to experience a similar upward trend during the forecast period. The growth in this region can be attributed to the strong presence of industries such as automotive, aerospace, and electronics, which are major consumers of VCI Foam. As these industries expand and innovate, the need for effective corrosion protection solutions like VCI Foam is likely to increase. The projected growth in the global and North American markets for VCI Foam underscores the importance of this material in safeguarding metal products from corrosion. As industries continue to evolve and face new challenges, the demand for reliable and efficient corrosion protection solutions like VCI Foam is expected to grow, further solidifying its role in the global market.

| Report Metric | Details |

| Report Name | VCI Foam - Market |

| Forecasted market size in 2030 | US$ 39 million |

| CAGR | 2.3% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Corrosion Resistance, Rust Prevention, ZERUST, Safepack, Anticorrosive sponges, IPS Packaging, KPR Adcor Inc, RUSTX, BENZ Packaging, Purchasekart, Aactus, BGR |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |