What is Material Transfer Isolator System (MT-IS) - Global Market?

The Material Transfer Isolator System (MT-IS) is a specialized technology designed to facilitate the safe and sterile transfer of materials in various industries, particularly in pharmaceuticals and biotechnology. These systems are crucial in maintaining a controlled environment that prevents contamination during the transfer process. MT-IS units are typically enclosed spaces that use advanced filtration and airflow systems to ensure that the materials being transferred remain uncontaminated by external factors. The global market for MT-IS is expanding as industries increasingly recognize the importance of maintaining product integrity and adhering to stringent regulatory standards. The systems are designed to be flexible and adaptable, catering to the specific needs of different applications, whether in research laboratories or large-scale pharmaceutical manufacturing. As the demand for high-quality, contamination-free products grows, the role of MT-IS in ensuring safe and efficient material transfer becomes even more critical. This technology not only enhances operational efficiency but also plays a vital role in safeguarding public health by ensuring that products are free from harmful contaminants. The global market for MT-IS is poised for significant growth, driven by advancements in technology and increasing awareness of the importance of maintaining sterile environments in critical industries.

Open Isolator, Closed Isolator in the Material Transfer Isolator System (MT-IS) - Global Market:

Open Isolators and Closed Isolators are two primary types of Material Transfer Isolator Systems (MT-IS) that serve distinct purposes in the global market. Open Isolators are designed to allow for some level of interaction with the external environment while still maintaining a controlled internal atmosphere. These systems are typically used in situations where operators need to access the materials being transferred without compromising the sterility of the environment. Open Isolators are equipped with sophisticated filtration systems that ensure any air entering or leaving the isolator is free from contaminants. This type of isolator is particularly useful in research settings where flexibility and ease of access are crucial. On the other hand, Closed Isolators provide a completely sealed environment, ensuring that the materials inside are entirely isolated from the external environment. These systems are essential in applications where absolute sterility is required, such as in the production of sterile pharmaceuticals or in handling highly sensitive biological materials. Closed Isolators are equipped with advanced air handling and filtration systems that create a barrier between the internal and external environments, preventing any potential contamination. The choice between Open and Closed Isolators depends on the specific requirements of the application, with factors such as the level of sterility needed, the nature of the materials being handled, and the operational workflow all playing a role in the decision-making process. Both types of isolators are integral to the MT-IS market, providing solutions that cater to a wide range of industrial needs. As industries continue to prioritize product integrity and regulatory compliance, the demand for both Open and Closed Isolators is expected to grow, driving innovation and development in this critical area of material transfer technology.

Pharmaceutical Companies, Research Laboratories, Others in the Material Transfer Isolator System (MT-IS) - Global Market:

Material Transfer Isolator Systems (MT-IS) play a pivotal role in various sectors, including pharmaceutical companies, research laboratories, and other industries that require sterile environments for material handling. In pharmaceutical companies, MT-IS are essential for ensuring that drugs and other medical products are manufactured in a contamination-free environment. These systems help maintain the sterility of raw materials and finished products, which is crucial for meeting regulatory standards and ensuring patient safety. By providing a controlled environment for material transfer, MT-IS enable pharmaceutical companies to produce high-quality products that are free from contaminants, thereby enhancing their reputation and market competitiveness. In research laboratories, MT-IS are used to protect sensitive experiments and materials from contamination. These systems are particularly important in fields such as microbiology, biotechnology, and chemical research, where even the slightest contamination can compromise the integrity of experiments and lead to inaccurate results. MT-IS provide a sterile environment that allows researchers to conduct experiments with confidence, knowing that their results will be reliable and reproducible. In addition to pharmaceuticals and research, MT-IS are also used in other industries where maintaining a sterile environment is critical. For example, in the food and beverage industry, MT-IS can be used to ensure that ingredients and finished products are free from contaminants, thereby enhancing product quality and safety. Similarly, in the electronics industry, MT-IS can be used to protect sensitive components from dust and other contaminants that could affect their performance. Overall, the versatility and effectiveness of MT-IS make them an invaluable tool in any industry where maintaining a sterile environment is essential for product quality and safety.

Material Transfer Isolator System (MT-IS) - Global Market Outlook:

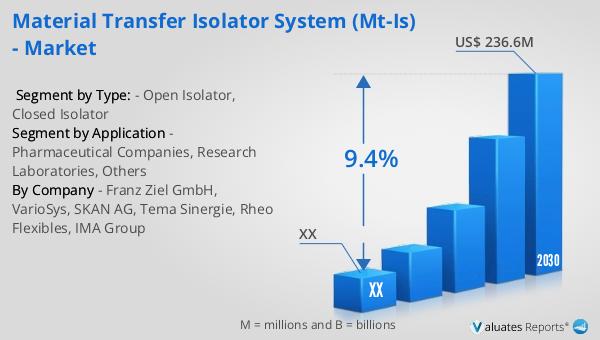

The global market for Material Transfer Isolator Systems (MT-IS) was valued at approximately $129 million in 2023, with projections indicating a growth to around $236.6 million by 2030. This represents a compound annual growth rate (CAGR) of 9.4% during the forecast period from 2024 to 2030. The increasing demand for MT-IS solutions is largely driven by the pharmaceutical, biotechnology, and research laboratory sectors, where maintaining sterile and controlled environments during material transfers is crucial. These systems are essential for ensuring product integrity and compliance with stringent regulatory standards. As industries continue to prioritize the production of high-quality, contamination-free products, the role of MT-IS in facilitating safe and efficient material transfer becomes increasingly important. The market growth is also supported by technological advancements that enhance the functionality and efficiency of these systems, making them more accessible and adaptable to a wide range of applications. As a result, the MT-IS market is expected to experience significant expansion, driven by the growing awareness of the importance of maintaining sterile environments in critical industries.

| Report Metric | Details |

| Report Name | Material Transfer Isolator System (MT-IS) - Market |

| Forecasted market size in 2030 | US$ 236.6 million |

| CAGR | 9.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Franz Ziel GmbH, VarioSys, SKAN AG, Tema Sinergie, Rheo Flexibles, IMA Group |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |