What is Rope Dyeing Machine - Global Market?

The Rope Dyeing Machine is a specialized piece of equipment used predominantly in the textile industry for dyeing yarns. This machine is integral to the process of creating denim and other fabrics that require a consistent and high-quality dye application. The global market for rope dyeing machines is driven by the demand for efficient and environmentally friendly dyeing processes. These machines are designed to handle large volumes of yarn, ensuring that each strand is uniformly dyed, which is crucial for maintaining the quality and appearance of the final fabric. The market is characterized by technological advancements that aim to reduce water and energy consumption, aligning with the growing emphasis on sustainable manufacturing practices. As textile manufacturers strive to meet stringent quality standards and environmental regulations, the adoption of advanced rope dyeing machines is expected to increase. This trend is further supported by the rising demand for denim and other dyed fabrics in the fashion industry, which continues to evolve with changing consumer preferences. The global market for rope dyeing machines is poised for growth as manufacturers seek to enhance their production capabilities while minimizing their environmental footprint.

Processing Time 3 Hours, Processing Time 4 Hours, Other in the Rope Dyeing Machine - Global Market:

In the global market for rope dyeing machines, processing time is a critical factor that influences the efficiency and cost-effectiveness of textile production. Machines with a processing time of 3 hours are designed to cater to manufacturers who prioritize speed and productivity. These machines are equipped with advanced features that allow for rapid dyeing cycles, enabling textile producers to meet tight deadlines and high-volume orders. The 3-hour processing time is particularly beneficial for manufacturers who operate in fast-paced environments, such as those producing fashion-forward garments that require quick turnaround times. On the other hand, machines with a processing time of 4 hours are tailored for manufacturers who emphasize precision and quality over speed. These machines offer a more controlled dyeing process, ensuring that the yarns are evenly dyed and free from defects. The 4-hour processing time allows for a more thorough dye penetration, which is essential for achieving deep and vibrant colors that are resistant to fading. This makes them ideal for producing high-end fabrics that demand superior quality and durability. Additionally, there are rope dyeing machines that offer customizable processing times, providing manufacturers with the flexibility to adjust the dyeing cycle according to their specific needs. These machines are equipped with programmable settings that allow operators to fine-tune the dyeing process, ensuring optimal results for different types of yarns and fabrics. The ability to customize processing times is particularly advantageous for manufacturers who produce a diverse range of products, as it enables them to adapt to varying production requirements without compromising on quality. Overall, the choice of processing time in rope dyeing machines is influenced by a variety of factors, including production volume, fabric type, and quality standards. Manufacturers must carefully consider these factors when selecting a machine to ensure that it aligns with their operational goals and market demands. As the global market for rope dyeing machines continues to evolve, manufacturers are increasingly seeking machines that offer a balance between speed, quality, and flexibility. This has led to the development of innovative machines that incorporate cutting-edge technology to enhance the dyeing process and meet the diverse needs of the textile industry.

Garment Industry, Other in the Rope Dyeing Machine - Global Market:

Rope dyeing machines play a pivotal role in the garment industry, particularly in the production of denim and other dyed fabrics. These machines are essential for achieving the rich, vibrant colors that are characteristic of high-quality garments. In the garment industry, the demand for rope dyeing machines is driven by the need for efficient and consistent dyeing processes that can handle large volumes of yarn. This is especially important for manufacturers who produce denim, as the dyeing process is a critical step in achieving the desired color and texture of the fabric. Rope dyeing machines are designed to ensure that each strand of yarn is uniformly dyed, which is crucial for maintaining the quality and appearance of the final garment. The use of these machines in the garment industry is further supported by the growing demand for sustainable and environmentally friendly manufacturing practices. As consumers become more conscious of the environmental impact of their clothing choices, manufacturers are increasingly adopting rope dyeing machines that are designed to minimize water and energy consumption. This not only helps to reduce the environmental footprint of the garment industry but also aligns with the industry's commitment to sustainability. In addition to their use in the garment industry, rope dyeing machines are also utilized in other sectors that require high-quality dyed fabrics. For example, these machines are used in the production of home textiles, such as curtains and upholstery, where the quality and consistency of the dyeing process are equally important. The versatility of rope dyeing machines makes them a valuable asset for manufacturers who produce a wide range of products, as they can be easily adapted to meet the specific requirements of different fabrics and applications. Overall, the global market for rope dyeing machines is driven by the demand for high-quality, sustainable dyeing processes in the garment industry and beyond. As manufacturers continue to seek innovative solutions to enhance their production capabilities and meet the evolving needs of consumers, the adoption of advanced rope dyeing machines is expected to increase.

Rope Dyeing Machine - Global Market Outlook:

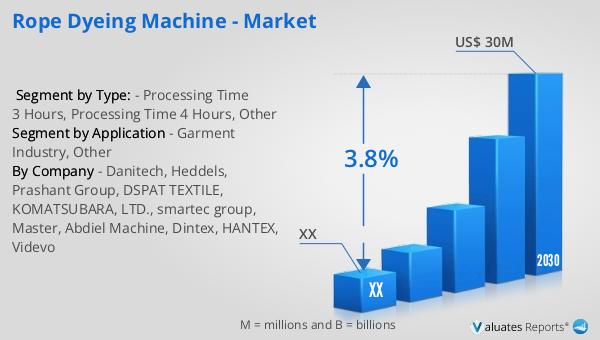

The global market for rope dyeing machines was valued at approximately $22 million in 2023, with projections indicating a growth to around $30 million by 2030. This growth, at a compound annual growth rate (CAGR) of 3.8% from 2024 to 2030, underscores the increasing demand for efficient and uniform dyeing processes in the textile industry. Textile manufacturers are under constant pressure to meet high-quality standards while also reducing their environmental impact. Rope dyeing machines are pivotal in achieving these objectives, as they offer a reliable solution for dyeing yarns uniformly and efficiently. The machines are designed to handle large volumes of yarn, ensuring consistent dye application, which is crucial for maintaining the quality and appearance of the final fabric. As the fashion industry continues to evolve with changing consumer preferences, the demand for dyed fabrics, particularly denim, is on the rise. This trend is further supported by the growing emphasis on sustainable manufacturing practices, as manufacturers seek to minimize their environmental footprint. The adoption of advanced rope dyeing machines is expected to increase as textile manufacturers strive to enhance their production capabilities while adhering to stringent quality standards and environmental regulations.

| Report Metric | Details |

| Report Name | Rope Dyeing Machine - Market |

| Forecasted market size in 2030 | US$ 30 million |

| CAGR | 3.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Danitech, Heddels, Prashant Group, DSPAT TEXTILE, KOMATSUBARA, LTD., smartec group, Master, Abdiel Machine, Dintex, HANTEX, Videvo |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |