What is Ultra-Clear Tubing - Global Market?

Ultra-clear tubing is a specialized type of tubing known for its exceptional transparency and clarity, making it ideal for applications where visual monitoring of fluid flow is crucial. This tubing is typically made from high-quality materials such as silicone or PVC, which provide excellent flexibility, durability, and resistance to various chemicals and environmental conditions. The global market for ultra-clear tubing is driven by its widespread use in industries that require precise monitoring and control of fluid dynamics, such as pharmaceuticals, biotechnology, food and beverage, and medical devices. These industries demand high-quality transparent tubing solutions to ensure the integrity and safety of their processes. The tubing's clarity allows for easy detection of blockages, contamination, or changes in fluid color, which is essential for maintaining quality control and ensuring the smooth operation of systems. As industries continue to prioritize safety, efficiency, and quality, the demand for ultra-clear tubing is expected to grow, making it a vital component in various applications worldwide. The market's growth is further supported by advancements in material technology, which enhance the tubing's performance and expand its range of applications.

10m, 20m, 30m, 50m, 100m in the Ultra-Clear Tubing - Global Market:

In the global market for ultra-clear tubing, different lengths such as 10m, 20m, 30m, 50m, and 100m cater to diverse industrial needs. The 10m length is often preferred for laboratory settings and small-scale operations where precise measurements and easy handling are crucial. Its compact size allows for efficient use in confined spaces, making it ideal for experiments and tests that require short runs of tubing. The 20m length is suitable for medium-sized applications, offering a balance between manageability and extended reach. This length is commonly used in pilot plants and small production facilities where slightly longer tubing runs are necessary. The 30m length provides even greater flexibility, accommodating larger setups in industries such as pharmaceuticals and biotechnology, where longer tubing is needed to connect various equipment and systems. The 50m length is favored in larger industrial applications, such as chemical processing and semiconductor manufacturing, where extensive tubing networks are required to transport fluids over greater distances. Finally, the 100m length is essential for large-scale operations, including fuel and oil industries, where long runs of tubing are necessary to connect distant points within a facility. Each length of ultra-clear tubing serves specific purposes, ensuring that industries can select the most appropriate size for their unique requirements. The availability of these varied lengths allows for customization and optimization of processes, enhancing efficiency and productivity across different sectors. As industries continue to evolve and expand, the demand for ultra-clear tubing in various lengths is expected to grow, driven by the need for reliable and high-performance tubing solutions. The versatility of ultra-clear tubing in accommodating different lengths and applications underscores its importance in the global market, making it an indispensable component in numerous industrial processes.

Chemical, Semiconductor, Laboratory, Fuel and Oil, Other in the Ultra-Clear Tubing - Global Market:

Ultra-clear tubing finds extensive usage across various sectors, including chemical, semiconductor, laboratory, fuel and oil, and other industries, due to its exceptional transparency and performance characteristics. In the chemical industry, ultra-clear tubing is crucial for processes that require precise monitoring of fluid flow and chemical reactions. Its transparency allows operators to visually inspect the flow of chemicals, ensuring that processes are running smoothly and safely. This is particularly important in applications where the mixing of chemicals needs to be closely monitored to prevent contamination or hazardous reactions. In the semiconductor industry, ultra-clear tubing is used in the manufacturing of electronic components, where the purity and integrity of fluids are paramount. The tubing's clarity enables technicians to detect any impurities or blockages that could compromise the quality of the final product. In laboratory settings, ultra-clear tubing is essential for experiments and tests that require accurate measurement and observation of fluid dynamics. Its flexibility and durability make it suitable for a wide range of laboratory applications, from simple fluid transfer to complex analytical procedures. In the fuel and oil industry, ultra-clear tubing is used for the transportation and monitoring of fuels and lubricants. Its transparency allows for the detection of impurities or changes in fluid color, which can indicate contamination or degradation of the product. This is critical for maintaining the quality and performance of fuels and oils in various applications. Additionally, ultra-clear tubing is used in other industries such as food and beverage, where it is essential for maintaining hygiene and quality control during the processing and packaging of products. The tubing's transparency allows for easy inspection of fluid flow, ensuring that products meet the required standards for safety and quality. Overall, the versatility and reliability of ultra-clear tubing make it an indispensable tool in a wide range of industrial applications, driving its demand in the global market.

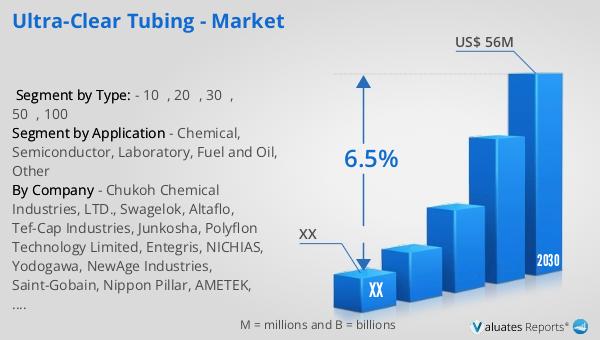

Ultra-Clear Tubing - Global Market Outlook:

The global market for ultra-clear tubing was valued at approximately $34 million in 2023, with projections indicating a growth to around $56 million by 2030, reflecting a compound annual growth rate (CAGR) of 6.5% during the forecast period from 2024 to 2030. This growth is largely driven by the increasing demand from industries such as pharmaceuticals, biotechnology, food and beverage, and medical devices, where ultra-clear tubing is essential for processes that require stringent monitoring and quality control of fluids, gases, or materials. The need for high-quality transparent tubing solutions in these sectors is paramount, as they ensure the integrity and safety of critical processes. In pharmaceuticals and biotechnology, for instance, ultra-clear tubing is used in the production and handling of sensitive compounds, where contamination or blockages could have serious implications. Similarly, in the food and beverage industry, the tubing's transparency allows for the visual inspection of fluid flow, ensuring that products meet the necessary safety and quality standards. The medical device industry also relies on ultra-clear tubing for applications such as fluid delivery systems, where precision and reliability are crucial. As these industries continue to grow and evolve, the demand for ultra-clear tubing is expected to increase, driving the market's expansion and highlighting the importance of high-quality transparent tubing solutions in various applications.

| Report Metric | Details |

| Report Name | Ultra-Clear Tubing - Market |

| Forecasted market size in 2030 | US$ 56 million |

| CAGR | 6.5% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Chukoh Chemical Industries, LTD., Swagelok, Altaflo, Tef-Cap Industries, Junkosha, Polyflon Technology Limited, Entegris, NICHIAS, Yodogawa, NewAge Industries, Saint-Gobain, Nippon Pillar, AMETEK, Adtech Polymer Engineering, Grayline, Fluorotherm, Habia Teknofluor, Xtraflex, PAR Group, Holscot, Bueno Technology |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |