What is Global Double Sided Rotary Tablet Press Machine Market?

The Global Double Sided Rotary Tablet Press Machine Market refers to the worldwide industry focused on the production, distribution, and utilization of machines designed to compress powder into tablets. These machines are essential in various industries, including pharmaceuticals, nutraceuticals, and food production, where they are used to create tablets of consistent size, shape, and weight. The "double-sided" aspect means that these machines can press tablets on both sides simultaneously, increasing efficiency and output. Rotary tablet press machines operate with a rotating turret that holds multiple tooling stations, allowing for continuous production. This market is driven by the growing demand for tablets in various sectors, advancements in technology, and the need for high-speed, high-efficiency production methods. The machines are valued for their precision, reliability, and ability to produce large quantities of tablets in a short period. As industries continue to expand and innovate, the demand for advanced tablet press machines is expected to grow, making this market a critical component of modern manufacturing processes.

Bi-Layer Tablet Press, Multi-Layer Tablet Press in the Global Double Sided Rotary Tablet Press Machine Market:

The Global Double Sided Rotary Tablet Press Machine Market includes various types of machines, such as Bi-Layer Tablet Press and Multi-Layer Tablet Press, each serving specific needs within the industry. A Bi-Layer Tablet Press is designed to produce tablets with two distinct layers, which can be beneficial for combining different active ingredients that may not be compatible in a single layer. This type of press is particularly useful in the pharmaceutical industry, where it allows for the creation of complex medication regimens in a single tablet, improving patient compliance and treatment efficacy. The Bi-Layer Tablet Press operates by compressing one layer of powder, then adding a second layer and compressing again, ensuring that the two layers are securely bonded. On the other hand, a Multi-Layer Tablet Press can produce tablets with more than two layers, offering even greater flexibility in tablet formulation. This type of press is used when there is a need to separate multiple active ingredients or to create tablets with different release profiles. For example, a multi-layer tablet might have an immediate-release layer for quick relief and a sustained-release layer for long-term efficacy. The Multi-Layer Tablet Press works similarly to the Bi-Layer Press but with additional stages for each layer, allowing for the precise control of each layer's composition and thickness. Both types of presses are integral to the Global Double Sided Rotary Tablet Press Machine Market, as they enable manufacturers to meet the diverse and complex needs of their customers. These machines are equipped with advanced features such as automated controls, real-time monitoring, and high-speed production capabilities, making them essential tools for modern manufacturing. The ability to produce multi-layer tablets also opens up new possibilities for innovation in product development, allowing companies to create unique and effective products that stand out in the market. As the demand for specialized and high-quality tablets continues to grow, the importance of Bi-Layer and Multi-Layer Tablet Presses in the Global Double Sided Rotary Tablet Press Machine Market cannot be overstated.

Pharmaceutical, Nutraceutical, Food Industry, Others in the Global Double Sided Rotary Tablet Press Machine Market:

The usage of Global Double Sided Rotary Tablet Press Machines spans several key industries, including pharmaceuticals, nutraceuticals, the food industry, and others. In the pharmaceutical industry, these machines are indispensable for the mass production of tablets, which are one of the most common forms of medication. They ensure that each tablet is of consistent quality, dosage, and appearance, which is crucial for patient safety and regulatory compliance. The ability to produce tablets with multiple layers also allows pharmaceutical companies to develop complex medications that can deliver multiple active ingredients or have different release profiles, enhancing treatment efficacy and patient adherence. In the nutraceutical industry, which includes dietary supplements and functional foods, Double Sided Rotary Tablet Press Machines are used to create tablets that deliver vitamins, minerals, and other beneficial compounds. These machines help manufacturers produce high-quality, consistent products that meet consumer demand for health and wellness solutions. The food industry also benefits from these machines, particularly in the production of items like effervescent tablets, chewable tablets, and other compressed food products. The precision and efficiency of Double Sided Rotary Tablet Press Machines ensure that these products are safe, effective, and appealing to consumers. Beyond these primary industries, these machines are also used in other sectors such as cosmetics, where they can be used to create compact powders and other pressed products. The versatility and reliability of Double Sided Rotary Tablet Press Machines make them valuable assets in any industry that requires the production of compressed tablets. Their ability to handle a wide range of materials and formulations, coupled with advanced features like automated controls and real-time monitoring, ensures that they can meet the diverse needs of modern manufacturing. As industries continue to innovate and expand, the role of Double Sided Rotary Tablet Press Machines in ensuring high-quality, efficient production will only become more critical.

Global Double Sided Rotary Tablet Press Machine Market Outlook:

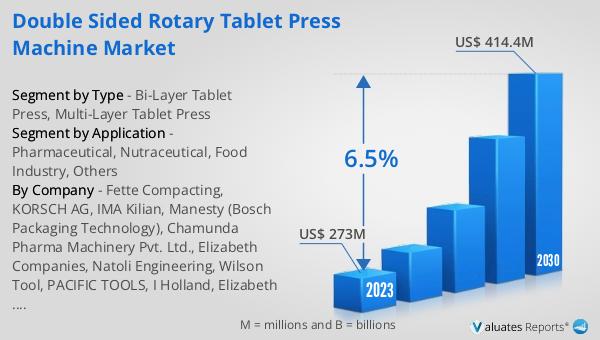

The global Double Sided Rotary Tablet Press Machine market was valued at US$ 273 million in 2023 and is anticipated to reach US$ 414.4 million by 2030, witnessing a CAGR of 6.5% during the forecast period 2024-2030. This market outlook highlights the significant growth potential of the industry, driven by increasing demand for high-efficiency tablet production across various sectors. The projected growth rate reflects the ongoing advancements in technology and the expanding applications of these machines in pharmaceuticals, nutraceuticals, and food production. As manufacturers seek to improve production efficiency and product quality, the adoption of Double Sided Rotary Tablet Press Machines is expected to rise. The market's growth is also supported by the need for precise and reliable tablet production methods, which these machines provide. With their ability to produce large quantities of tablets quickly and consistently, Double Sided Rotary Tablet Press Machines are becoming essential tools in modern manufacturing. The anticipated increase in market value underscores the importance of these machines in meeting the evolving needs of various industries and highlights the opportunities for innovation and development within the market.

| Report Metric | Details |

| Report Name | Double Sided Rotary Tablet Press Machine Market |

| Accounted market size in 2023 | US$ 273 million |

| Forecasted market size in 2030 | US$ 414.4 million |

| CAGR | 6.5% |

| Base Year | 2023 |

| Forecasted years | 2024 - 2030 |

| Segment by Type |

|

| Segment by Application |

|

| Production by Region |

|

| Consumption by Region |

|

| By Company | Fette Compacting, KORSCH AG, IMA Kilian, Manesty (Bosch Packaging Technology), Chamunda Pharma Machinery Pvt. Ltd., Elizabeth Companies, Natoli Engineering, Wilson Tool, PACIFIC TOOLS, I Holland, Elizabeth group, Pharmachine, NANNO Co., Ltd., Adamus SA, Rotek Pharma Technologies, PTK-GB Ltd., Karnavati Engineering, Jayshree Tablet Science, CMC Machinery LLC, JCMCO, SHAPER, Syntegon |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |