What is Medical PCB - Global Market?

Medical printed circuit boards (PCBs) are essential components in the global healthcare industry, serving as the backbone for a wide range of medical devices. These PCBs are specifically designed to meet the stringent requirements of medical applications, where reliability, precision, and safety are paramount. The global market for medical PCBs is driven by the increasing demand for advanced medical devices that offer improved diagnostics, monitoring, and treatment capabilities. As healthcare technology continues to evolve, the need for sophisticated PCBs that can support complex functionalities is growing. Medical PCBs are used in various applications, including imaging systems, patient monitoring devices, and implantable devices like pacemakers. The market is characterized by continuous innovation, with manufacturers focusing on developing PCBs that are smaller, more efficient, and capable of handling higher data processing speeds. Additionally, the trend towards miniaturization and the integration of multiple functions into single devices is further propelling the demand for advanced medical PCBs. As a result, the medical PCB market is poised for significant growth, driven by technological advancements and the increasing adoption of electronic health solutions worldwide.

Flex PCB, Rigid PCB, High-Density Interconnect (HDI) PCB, Other in the Medical PCB - Global Market:

Flex PCBs, rigid PCBs, and high-density interconnect (HDI) PCBs are integral components of the medical PCB global market, each serving distinct roles in the design and functionality of medical devices. Flex PCBs, known for their flexibility and lightweight nature, are particularly valuable in medical applications where space and weight are critical considerations. These PCBs can be bent and folded to fit into compact spaces, making them ideal for wearable medical devices and implantable technologies. Their ability to withstand dynamic movements without compromising performance is crucial in applications such as flexible endoscopes and portable diagnostic equipment. On the other hand, rigid PCBs are known for their durability and stability, making them suitable for devices that require a solid and reliable platform. They are commonly used in larger medical equipment like MRI machines and CT scanners, where structural integrity is essential. Rigid PCBs provide a stable base for complex circuitry and are capable of supporting high-power applications, ensuring consistent performance in demanding environments. High-density interconnect (HDI) PCBs represent the cutting edge of PCB technology, offering increased circuit density and enhanced performance. These PCBs are designed to accommodate more components in a smaller area, making them ideal for advanced medical devices that require high-speed data processing and miniaturization. HDI PCBs are often used in sophisticated medical imaging systems and advanced diagnostic equipment, where precision and speed are critical. The ability to integrate multiple functions into a single PCB allows for more compact and efficient device designs, meeting the growing demand for portable and user-friendly medical technologies. Other types of PCBs, such as those with specialized coatings or materials, are also gaining traction in the medical market. These PCBs are designed to withstand harsh environments, such as those encountered in sterilization processes or within the human body. The use of biocompatible materials and advanced manufacturing techniques ensures that these PCBs can safely and effectively operate in medical applications. Overall, the diverse range of PCBs available in the medical market reflects the industry's commitment to innovation and the development of cutting-edge solutions that enhance patient care and improve healthcare outcomes.

Imaging Devices, Pacemakers, Electronic Health Records (EHRs), Monitoring Devices, Other in the Medical PCB - Global Market:

Medical PCBs play a crucial role in various healthcare applications, providing the necessary infrastructure for advanced medical technologies. In imaging devices, such as MRI machines, CT scanners, and ultrasound equipment, PCBs are responsible for processing complex data and ensuring accurate image generation. These devices rely on high-performance PCBs to handle the vast amounts of data generated during imaging procedures, enabling healthcare professionals to diagnose and treat patients effectively. The precision and reliability of PCBs in these applications are critical, as any malfunction could lead to incorrect diagnoses or treatment plans. In pacemakers, medical PCBs are used to control the electrical impulses that regulate heartbeats. These implantable devices require PCBs that are not only compact and efficient but also biocompatible and capable of withstanding the harsh conditions within the human body. The reliability of PCBs in pacemakers is vital, as any failure could have life-threatening consequences for patients. Electronic Health Records (EHRs) systems also benefit from the use of advanced PCBs, which facilitate the secure and efficient storage and retrieval of patient data. These systems rely on PCBs to manage large volumes of information, ensuring that healthcare providers have access to accurate and up-to-date patient records. In monitoring devices, such as blood glucose monitors and wearable fitness trackers, PCBs enable the continuous collection and analysis of patient data. These devices require PCBs that are both compact and energy-efficient, allowing for extended use without frequent recharging. The ability to provide real-time data is essential in monitoring applications, as it enables timely interventions and personalized treatment plans. Other medical applications, such as surgical instruments and laboratory equipment, also rely on PCBs to enhance functionality and improve performance. The versatility and adaptability of PCBs make them indispensable in the medical field, supporting a wide range of devices that contribute to better patient care and improved healthcare outcomes.

Medical PCB - Global Market Outlook:

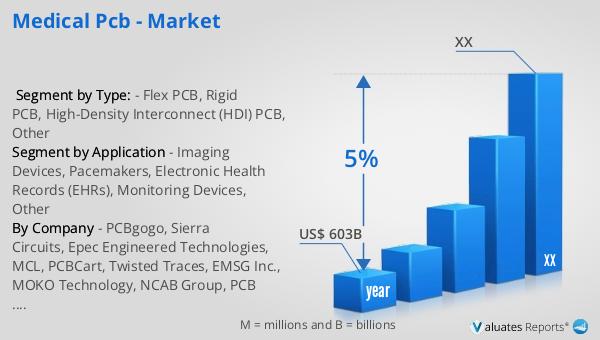

Based on our research, the global market for medical devices is projected to reach approximately $603 billion in 2023, with an anticipated growth rate of 5% annually over the next six years. This growth trajectory underscores the increasing demand for advanced medical technologies and the pivotal role that medical PCBs play in this expanding market. As healthcare systems worldwide continue to adopt electronic solutions to improve patient care and streamline operations, the demand for reliable and efficient PCBs is expected to rise. The integration of PCBs into medical devices enhances their functionality, enabling more precise diagnostics, effective monitoring, and improved treatment outcomes. The projected growth of the medical device market reflects the ongoing advancements in healthcare technology and the increasing reliance on electronic components to drive innovation. As the market expands, manufacturers are likely to focus on developing PCBs that meet the evolving needs of the healthcare industry, including miniaturization, increased functionality, and enhanced reliability. The global market outlook for medical devices highlights the critical role that PCBs play in shaping the future of healthcare, providing the foundation for cutting-edge technologies that improve patient outcomes and enhance the overall quality of care.

| Report Metric | Details |

| Report Name | Medical PCB - Market |

| Accounted market size in year | US$ 603 billion |

| CAGR | 5% |

| Base Year | year |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | PCBgogo, Sierra Circuits, Epec Engineered Technologies, MCL, PCBCart, Twisted Traces, EMSG Inc., MOKO Technology, NCAB Group, PCB Connect, Valtronic, EBICS, PCBWay, Bittele Electronics, TTM Technologies, Pramura, Altek Electronics, Rayming, Printed Circuits LLC, VSE, SFI Circuits, GS Swiss PCB AG, Micro Systems Technologies Managemen |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |