What is Alternative Protein Processing Equipment - Global Market?

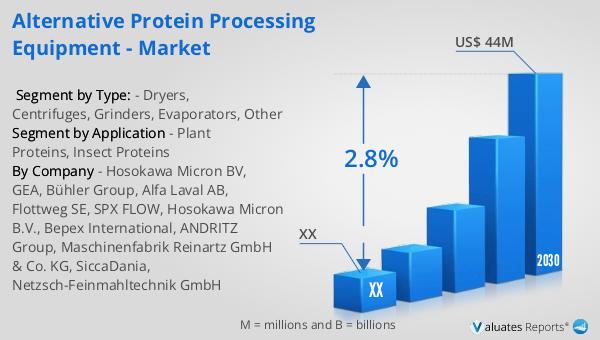

Alternative protein processing equipment is a crucial component in the burgeoning global market for alternative proteins, which includes plant-based, insect-based, and lab-grown proteins. These proteins are gaining popularity as sustainable and ethical alternatives to traditional animal proteins. The equipment used in processing these proteins is designed to efficiently extract, refine, and produce high-quality protein products. This market is driven by increasing consumer demand for healthier and more environmentally friendly food options. The equipment includes a variety of machines such as dryers, centrifuges, grinders, and evaporators, each playing a specific role in the protein production process. As the demand for alternative proteins continues to rise, the market for processing equipment is expected to grow, providing opportunities for manufacturers to innovate and improve their technologies. The global market for alternative protein processing equipment was valued at approximately $37 million in 2023, with projections indicating a growth to $44 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.8% during the forecast period from 2024 to 2030. This growth is indicative of the increasing importance of alternative proteins in the global food industry and the need for efficient processing solutions.

Dryers, Centrifuges, Grinders, Evaporators, Other in the Alternative Protein Processing Equipment - Global Market:

Dryers, centrifuges, grinders, evaporators, and other equipment are integral to the alternative protein processing industry, each serving a unique function in the production of high-quality protein products. Dryers are essential for removing moisture from protein sources, ensuring a longer shelf life and stability of the final product. They are particularly important in the production of plant-based proteins, where moisture content can affect texture and taste. Centrifuges, on the other hand, are used to separate different components of the protein mixture, such as fats and liquids, to achieve the desired purity and concentration. This is crucial in both plant and insect protein processing, where the separation of components can significantly impact the quality of the end product. Grinders are used to break down raw materials into smaller particles, facilitating easier processing and extraction of proteins. This equipment is vital in the initial stages of protein production, where raw materials need to be prepared for further processing. Evaporators are employed to concentrate protein solutions by removing excess water, enhancing the protein content and improving the efficiency of the production process. This step is particularly important in the production of liquid protein products, where concentration levels can affect the nutritional value and application of the product. Other equipment used in alternative protein processing includes mixers, homogenizers, and filtration systems, each contributing to the refinement and quality of the final protein product. Mixers ensure uniform distribution of ingredients, while homogenizers break down particles to create a smooth and consistent texture. Filtration systems are used to remove impurities and ensure the purity of the protein product. The integration of these various pieces of equipment is essential for the efficient and effective production of alternative proteins, meeting the growing consumer demand for sustainable and ethical food options. As the market for alternative proteins continues to expand, the demand for advanced processing equipment is expected to increase, driving innovation and technological advancements in the industry. Manufacturers are focusing on developing equipment that is not only efficient but also environmentally friendly, aligning with the sustainability goals of the alternative protein industry. This includes the use of energy-efficient technologies and the reduction of waste in the production process. The global market for alternative protein processing equipment is poised for growth, with increasing investments in research and development to improve the efficiency and effectiveness of these machines. As consumer preferences shift towards healthier and more sustainable food options, the role of processing equipment in the alternative protein industry becomes increasingly important, providing opportunities for manufacturers to capitalize on this growing trend.

Plant Proteins, Insect Proteins in the Alternative Protein Processing Equipment - Global Market:

The usage of alternative protein processing equipment in the production of plant and insect proteins is a testament to the versatility and adaptability of these machines. In the realm of plant proteins, equipment such as grinders and dryers play a pivotal role in transforming raw plant materials into consumable protein products. Grinders are used to break down plant materials like soybeans, peas, and lentils into smaller particles, facilitating the extraction of proteins. This process is crucial in ensuring that the proteins are easily accessible and can be efficiently processed into various forms, such as powders or textured products. Dryers are then used to remove moisture from the extracted proteins, ensuring a stable and long-lasting product. This step is particularly important in maintaining the quality and shelf life of plant-based protein products, which are often used as meat substitutes in various culinary applications. Insect proteins, on the other hand, require a slightly different approach in processing. The use of centrifuges and evaporators is more prevalent in this area, as these machines are adept at handling the unique properties of insect-based materials. Centrifuges are used to separate the protein-rich components from other parts of the insect, such as fats and chitin, ensuring a pure and concentrated protein product. This separation process is crucial in maintaining the nutritional value and quality of insect proteins, which are gaining popularity as a sustainable and efficient source of nutrition. Evaporators are then used to concentrate the protein solutions, enhancing their protein content and making them suitable for various applications, such as protein bars, powders, and supplements. The integration of these processing techniques is essential in meeting the growing demand for alternative proteins, providing consumers with a diverse range of options that cater to different dietary preferences and needs. As the market for alternative proteins continues to expand, the role of processing equipment becomes increasingly important in ensuring the quality, efficiency, and sustainability of protein production. Manufacturers are investing in research and development to improve the capabilities of these machines, focusing on energy efficiency, waste reduction, and the ability to handle a wide range of raw materials. This innovation is crucial in supporting the growth of the alternative protein industry, providing consumers with high-quality and sustainable protein options that align with their values and dietary preferences. The global market for alternative protein processing equipment is set to grow, driven by the increasing demand for plant and insect proteins and the need for efficient and effective processing solutions. As consumer awareness of the environmental and health benefits of alternative proteins continues to rise, the importance of processing equipment in this industry cannot be overstated, providing opportunities for manufacturers to capitalize on this growing trend.

Alternative Protein Processing Equipment - Global Market Outlook:

The global market for alternative protein processing equipment was valued at approximately $37 million in 2023, with projections indicating a growth to $44 million by 2030, reflecting a compound annual growth rate (CAGR) of 2.8% during the forecast period from 2024 to 2030. This growth is indicative of the increasing importance of alternative proteins in the global food industry and the need for efficient processing solutions. The North American market, in particular, is expected to see significant growth, driven by increasing consumer demand for healthier and more sustainable food options. While specific figures for the North American market were not provided, it is clear that the region will play a crucial role in the overall growth of the alternative protein processing equipment market. This growth is supported by a strong focus on innovation and technological advancements in the industry, with manufacturers investing in research and development to improve the efficiency and effectiveness of their equipment. As consumer preferences continue to shift towards healthier and more sustainable food options, the demand for advanced processing equipment is expected to increase, providing opportunities for manufacturers to capitalize on this growing trend. The global market for alternative protein processing equipment is poised for growth, with increasing investments in research and development to improve the efficiency and effectiveness of these machines. As consumer awareness of the environmental and health benefits of alternative proteins continues to rise, the importance of processing equipment in this industry cannot be overstated, providing opportunities for manufacturers to capitalize on this growing trend.

| Report Metric | Details |

| Report Name | Alternative Protein Processing Equipment - Market |

| Forecasted market size in 2030 | US$ 44 million |

| CAGR | 2.8% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Hosokawa Micron BV, GEA, Bühler Group, Alfa Laval AB, Flottweg SE, SPX FLOW, Hosokawa Micron B.V., Bepex International, ANDRITZ Group, Maschinenfabrik Reinartz GmbH & Co. KG, SiccaDania, Netzsch-Feinmahltechnik GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |