What is Fish Feed Extruder Machine - Global Market?

Fish feed extruder machines are specialized equipment used in the production of fish feed pellets. These machines play a crucial role in the aquaculture industry by transforming raw materials into high-quality feed that meets the nutritional needs of various fish species. The global market for fish feed extruder machines is driven by the increasing demand for aquaculture products, as fish farming becomes a more sustainable and efficient way to meet the world's growing protein needs. These machines are designed to produce feed that is easily digestible and nutritionally balanced, ensuring optimal growth and health for fish. The market encompasses a range of extruder types, including dry and wet variants, each suited to different production requirements and scales. As the aquaculture industry continues to expand, the demand for advanced and efficient fish feed extruder machines is expected to grow, driven by technological advancements and the need for sustainable fish farming practices. The market is characterized by a diverse range of manufacturers and suppliers, offering machines with varying capacities and features to cater to the specific needs of fish farmers worldwide.

Dry Type, Wet Type in the Fish Feed Extruder Machine - Global Market:

Fish feed extruder machines are broadly categorized into two types: dry type and wet type, each with distinct features and applications. The dry type fish feed extruder machine is known for its simplicity and cost-effectiveness. It operates without the need for a steam boiler, making it a more economical choice for small to medium-sized fish farms. This type of machine uses mechanical pressure and heat generated by the friction of the screw to cook and extrude the feed. The dry type extruder is suitable for producing floating feed pellets, which are ideal for surface-feeding fish species. Its compact design and ease of operation make it a popular choice among fish farmers who require a straightforward and efficient solution for feed production. On the other hand, the wet type fish feed extruder machine is equipped with a conditioner and requires a steam boiler for operation. This type of machine is capable of producing both floating and sinking feed pellets, making it versatile for different fish species with varying feeding habits. The wet type extruder is often used in larger fish farms and commercial feed production facilities due to its higher capacity and ability to produce a wider range of feed types. It offers better control over the cooking process, resulting in feed with improved digestibility and nutritional quality. The choice between dry and wet type extruders depends on several factors, including the scale of production, the specific nutritional requirements of the fish species being farmed, and the available budget for equipment investment. Both types of machines contribute significantly to the efficiency and sustainability of fish farming operations by enabling the production of high-quality feed that supports the health and growth of fish. As the global aquaculture industry continues to evolve, the demand for both dry and wet type fish feed extruder machines is expected to increase, driven by the need for innovative and efficient feed production solutions. Manufacturers are continually developing new technologies and features to enhance the performance and versatility of these machines, ensuring they meet the diverse needs of fish farmers around the world.

Freshwater Fishes, Saltwater Fishes in the Fish Feed Extruder Machine - Global Market:

Fish feed extruder machines are essential tools in the aquaculture industry, particularly for the production of feed for freshwater and saltwater fish species. In freshwater aquaculture, these machines are used to produce feed for a variety of fish species, including tilapia, catfish, and carp. Freshwater fish farming is a significant contributor to global fish production, and the use of extruder machines ensures that the feed produced is nutritionally balanced and suitable for the specific dietary needs of these fish. The ability to produce floating feed pellets is particularly beneficial for freshwater species that feed at the surface, as it allows for better feed management and reduces waste. In saltwater aquaculture, fish feed extruder machines are used to produce feed for species such as salmon, sea bass, and shrimp. Saltwater fish farming presents unique challenges, including the need for feed that can withstand the harsh marine environment and meet the high energy requirements of these species. Extruder machines are capable of producing high-energy feed pellets that are both durable and palatable, ensuring optimal growth and health for saltwater fish. The versatility of fish feed extruder machines allows for the production of feed with varying sizes, shapes, and nutritional profiles, catering to the diverse needs of different fish species. This adaptability is crucial in both freshwater and saltwater aquaculture, where the nutritional requirements of fish can vary significantly depending on factors such as species, age, and environmental conditions. By providing a reliable and efficient means of producing high-quality feed, fish feed extruder machines play a vital role in supporting the growth and sustainability of the global aquaculture industry. As the demand for fish and seafood continues to rise, the importance of these machines in ensuring the availability of nutritious and sustainable feed cannot be overstated.

Fish Feed Extruder Machine - Global Market Outlook:

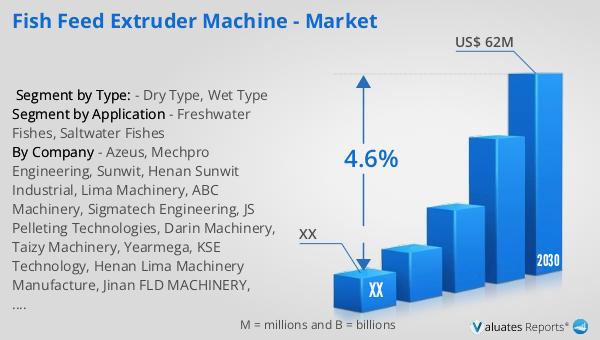

The global market for fish feed extruder machines was valued at approximately $45 million in 2023. This market is projected to grow steadily, reaching an estimated value of $62 million by 2030. This growth represents a compound annual growth rate (CAGR) of 4.6% during the forecast period from 2024 to 2030. The increasing demand for fish feed extruder machines is driven by the expanding aquaculture industry, which requires efficient and sustainable feed production solutions to meet the growing demand for fish and seafood products. As fish farming becomes more prevalent worldwide, the need for advanced and reliable feed production equipment is expected to rise. The market is characterized by a diverse range of manufacturers and suppliers, offering machines with varying capacities and features to cater to the specific needs of fish farmers. Technological advancements and innovations in feed production processes are also contributing to the growth of the market, as manufacturers strive to develop machines that offer improved efficiency, versatility, and sustainability. The global market for fish feed extruder machines is poised for continued growth, driven by the increasing demand for high-quality and sustainable fish feed in the aquaculture industry.

| Report Metric | Details |

| Report Name | Fish Feed Extruder Machine - Market |

| Forecasted market size in 2030 | US$ 62 million |

| CAGR | 4.6% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Azeus, Mechpro Engineering, Sunwit, Henan Sunwit Industrial, Lima Machinery, ABC Machinery, Sigmatech Engineering, JS Pelleting Technologies, Darin Machinery, Taizy Machinery, Yearmega, KSE Technology, Henan Lima Machinery Manufacture, Jinan FLD MACHINERY, RICHI MACHINERY, Wuhan Extruder Machine Merchandise, SHANDONG FOREVER MACHINERY |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |