What is Stainless Steel 3D Printing Material - Global Market?

Stainless steel 3D printing material is a significant component in the global market, offering a versatile and durable option for various industries. This material is primarily used in additive manufacturing, a process that builds objects layer by layer, allowing for complex designs and reduced waste. Stainless steel is favored for its strength, corrosion resistance, and ability to withstand high temperatures, making it ideal for producing parts that require durability and precision. The global market for stainless steel 3D printing material is expanding as industries such as aerospace, automotive, and healthcare increasingly adopt 3D printing technologies. This growth is driven by the demand for customized and efficient manufacturing solutions. The material's adaptability to different 3D printing technologies, such as selective laser melting and direct metal laser sintering, further enhances its appeal. As industries continue to innovate and seek sustainable manufacturing methods, the demand for stainless steel 3D printing material is expected to rise, reflecting its importance in modern production processes. The market's expansion is also supported by advancements in 3D printing technology, which improve the quality and efficiency of stainless steel parts, making them more accessible and cost-effective for various applications.

Austenitic Stainless Steels, Duplex Stainless Steels, Others in the Stainless Steel 3D Printing Material - Global Market:

Austenitic stainless steels are a popular choice in the stainless steel 3D printing material market due to their excellent corrosion resistance and formability. These steels are characterized by their high chromium and nickel content, which provides superior resistance to rust and staining. In the context of 3D printing, austenitic stainless steels are used to produce components that require a high degree of durability and resistance to harsh environments. Their non-magnetic properties also make them suitable for applications where magnetic interference must be minimized. The versatility of austenitic stainless steels allows them to be used in a wide range of industries, including aerospace, automotive, and medical devices. Duplex stainless steels, on the other hand, offer a unique combination of austenitic and ferritic stainless steel properties. They are known for their high strength and excellent corrosion resistance, particularly in chloride-rich environments. This makes them ideal for applications in the chemical and oil and gas industries, where exposure to corrosive substances is common. Duplex stainless steels are also used in the construction of bridges and other infrastructure projects due to their strength and durability. The use of duplex stainless steels in 3D printing allows for the creation of complex geometries that are both strong and resistant to corrosion, making them a valuable material in the global market. Other types of stainless steels used in 3D printing include martensitic and precipitation-hardening stainless steels. Martensitic stainless steels are known for their high strength and hardness, making them suitable for applications that require wear resistance and toughness. These steels are often used in the production of tools and machinery components. Precipitation-hardening stainless steels, on the other hand, offer a combination of high strength and corrosion resistance, making them ideal for aerospace and defense applications. The global market for stainless steel 3D printing material is diverse, with each type of stainless steel offering unique properties that cater to specific industry needs. As the demand for 3D printed components continues to grow, the market for stainless steel 3D printing materials is expected to expand, driven by the need for high-performance materials that can withstand challenging environments and complex manufacturing requirements.

Food and Beverage, Chemical, Enclosures, Consumer Products, Others in the Stainless Steel 3D Printing Material - Global Market:

The use of stainless steel 3D printing material in the global market spans various industries, each benefiting from the material's unique properties. In the food and beverage industry, stainless steel is used to produce components that come into direct contact with food products. Its corrosion resistance and ease of cleaning make it an ideal choice for manufacturing food processing equipment, ensuring hygiene and safety standards are met. The ability to create complex shapes and designs through 3D printing allows for the customization of equipment to meet specific processing needs, enhancing efficiency and productivity. In the chemical industry, stainless steel 3D printing material is used to produce components that must withstand harsh chemical environments. Its resistance to corrosion and high temperatures makes it suitable for manufacturing parts used in chemical processing plants, such as reactors, heat exchangers, and piping systems. The ability to produce intricate designs through 3D printing allows for the optimization of fluid dynamics and heat transfer, improving the overall efficiency of chemical processes. Stainless steel's durability and strength also make it a preferred material for enclosures used in various applications. In the consumer products sector, stainless steel 3D printing material is used to create a wide range of products, from kitchenware to electronic device components. Its aesthetic appeal, combined with its durability and resistance to wear and tear, makes it an attractive choice for manufacturers looking to produce high-quality consumer goods. The ability to customize designs through 3D printing allows for the creation of unique and innovative products that cater to consumer preferences. Other applications of stainless steel 3D printing material include the production of medical devices, automotive components, and aerospace parts. In the medical field, stainless steel is used to produce surgical instruments and implants due to its biocompatibility and resistance to corrosion. In the automotive and aerospace industries, stainless steel's strength and durability make it suitable for producing components that must withstand high stress and extreme conditions. The versatility and adaptability of stainless steel 3D printing material make it a valuable resource in the global market, offering solutions for a wide range of applications across various industries.

Stainless Steel 3D Printing Material - Global Market Outlook:

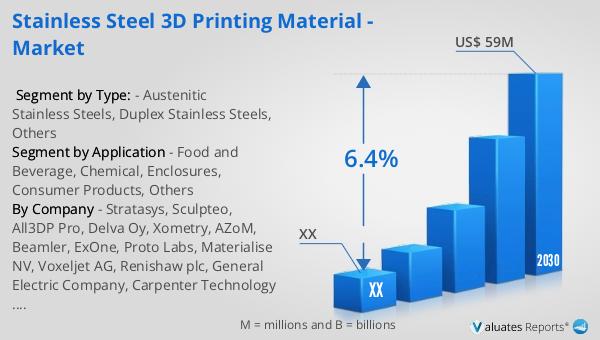

In 2023, the global market for stainless steel 3D printing material was valued at approximately $42 million. This market is projected to grow significantly, reaching an estimated value of $59 million by the year 2030. This growth represents a compound annual growth rate (CAGR) of 6.4% during the forecast period from 2024 to 2030. The increasing adoption of 3D printing technologies across various industries is a key driver of this market expansion. As industries continue to seek efficient and sustainable manufacturing solutions, the demand for stainless steel 3D printing material is expected to rise. This material's unique properties, such as its strength, corrosion resistance, and ability to withstand high temperatures, make it an attractive option for producing durable and precise components. The market's growth is also supported by advancements in 3D printing technology, which enhance the quality and efficiency of stainless steel parts. As a result, stainless steel 3D printing material is becoming more accessible and cost-effective for a wide range of applications. The projected growth of this market reflects the increasing importance of stainless steel 3D printing material in modern manufacturing processes, as industries continue to innovate and adapt to changing demands.

| Report Metric | Details |

| Report Name | Stainless Steel 3D Printing Material - Market |

| Forecasted market size in 2030 | US$ 59 million |

| CAGR | 6.4% |

| Forecasted years | 2024 - 2030 |

| Segment by Type: |

|

| Segment by Application |

|

| By Region |

|

| By Company | Stratasys, Sculpteo, All3DP Pro, Delva Oy, Xometry, AZoM, Beamler, ExOne, Proto Labs, Materialise NV, Voxeljet AG, Renishaw plc, General Electric Company, Carpenter Technology Corporation, 3D Systems Corporation, EOS GmbH |

| Forecast units | USD million in value |

| Report coverage | Revenue and volume forecast, company share, competitive landscape, growth factors and trends |